UM-PRORUNNER_Mk5-1.2-EN-US 35

Description

Requirements for the product carrier

The product carrier must be mounted correctly

on the carrier axis.For a mounting example

refer to the instructions for the mounting

carrier. The product carrier must provide stable

support for the product during pick up and

movement. During the pass through of circular

movement, horizontal accelerations occur. The

product carrier must be strong enough to

capture the static and dynamic forces in order

to prevent damage to the product and parts of

the machine. During the pick up of a product a

peak load occurs. The stiffness of the product

carrier along with the product weight, product

geometry, and the speed of the carrier

determines the height of the peak load. To

reduce peak loads, place resilient materials between the product and the product carrier.

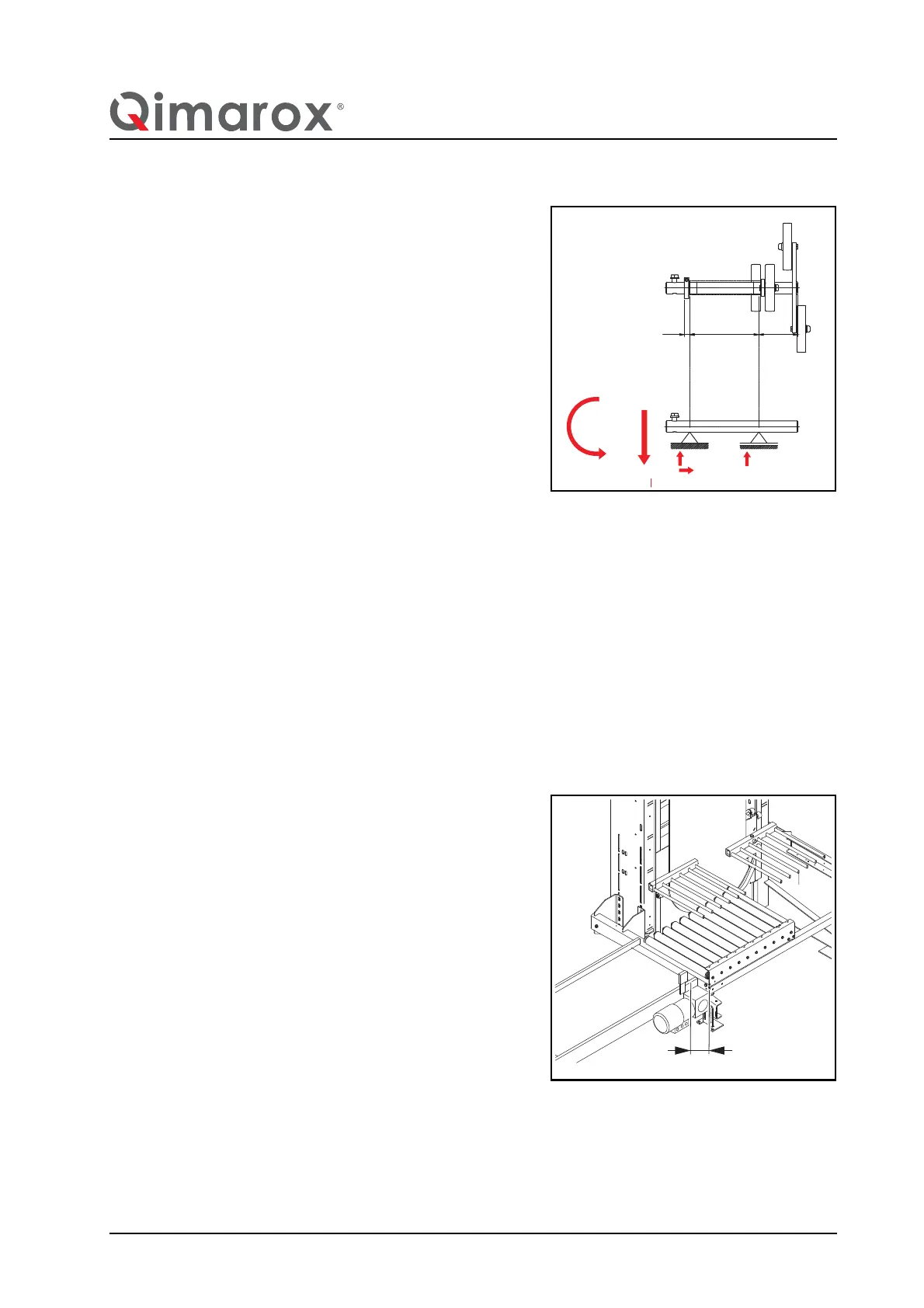

The center of gravity of the product carrier must be on the centerline of the leveler. The

center of gravity of the product must be about the vertical surface through the carrier axis.

Calculation of the product carrier

The maximal permitted load on the carrier axis is limited by the strength of the carrier axis.

The forces on the carrier axis are determined by the weight of the carrier, the weight of the

product, and acceleration forces during pick up of the product. The forces during pick up of

the product can be considered as a collision of the product with a resilient carrier, and then

make an estimation of the maximal force that occurs.The carrier axis can be considered as

a layer with support points on both ends and is loaded by a force and a moment. This

calculation can be checked by Qimarox on request.

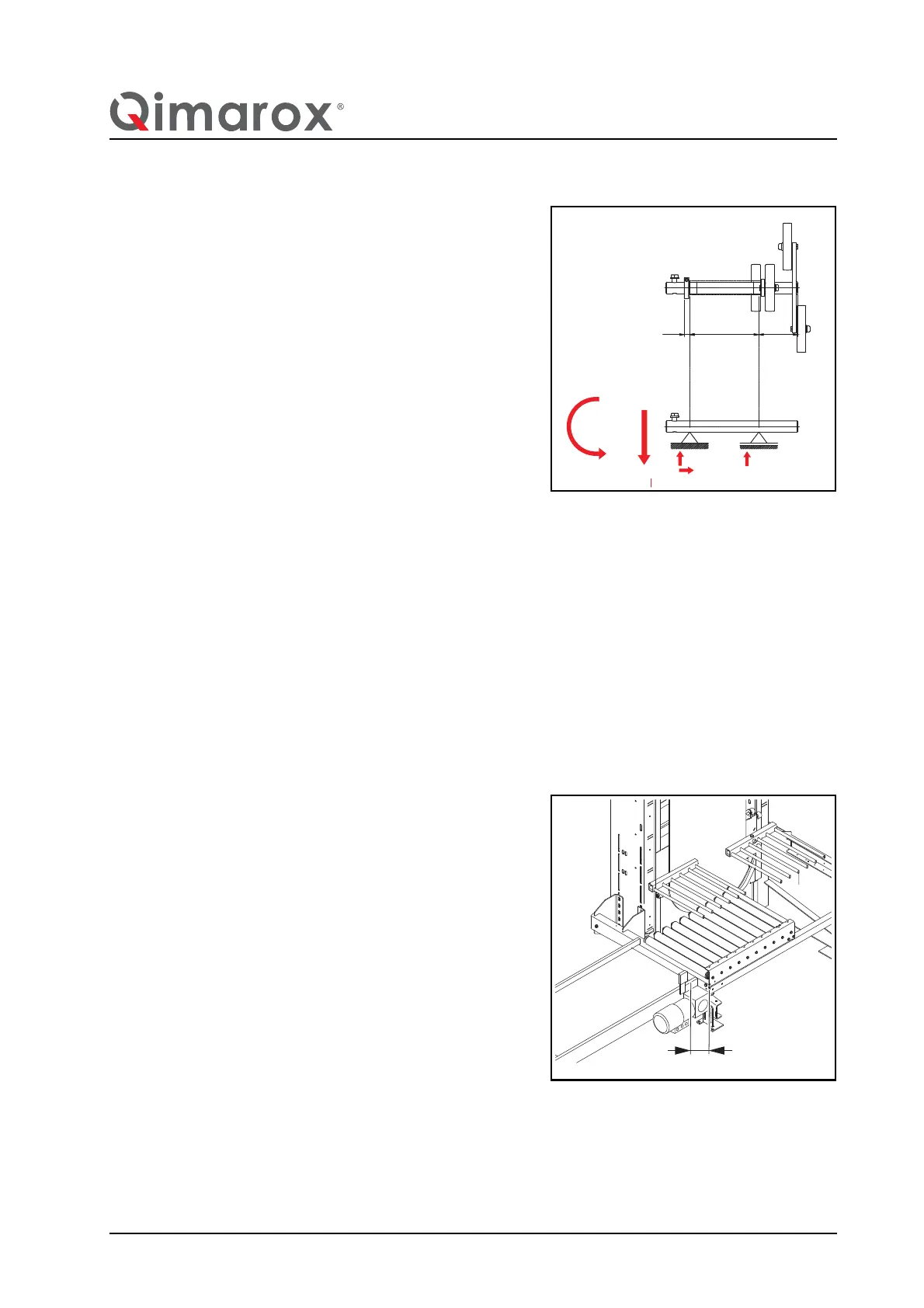

4.3.3 Specification of gap between conveyors

The maximum allowed gap (A) between supply

/ output conveyor and infeed / outfeed

conveyor is 25 mm.

Loading...

Loading...