UM-PRORUNNER_Mk5-1.2-EN-US 91

Maintenance belt conveyor

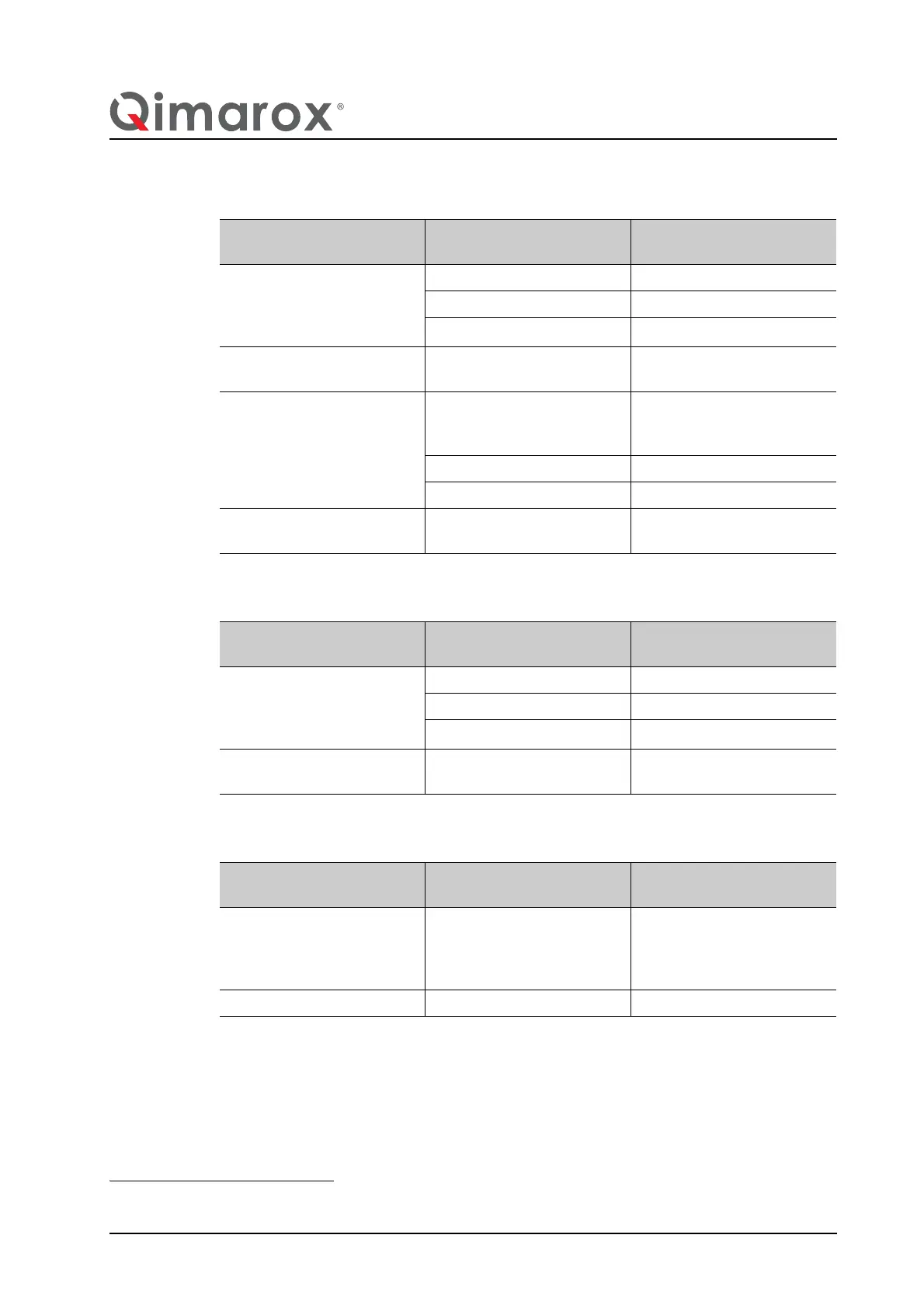

9.2.3 Monthly maintenance

/i

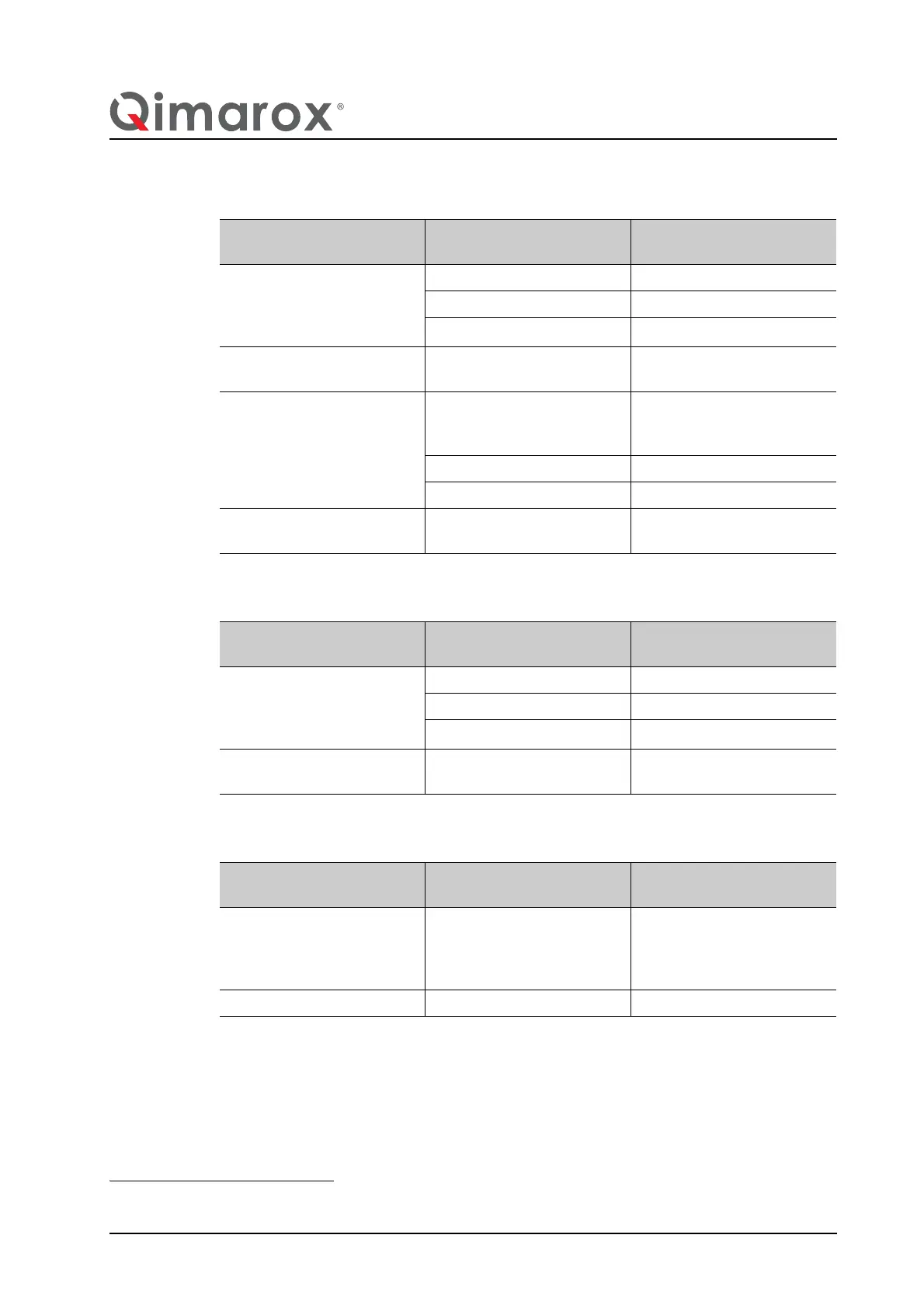

9.2.4 6-monthly maintenance

/i

9.2.5 2-yearly maintenance

1

/i

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Check the seals for leakage. Replace the seals.

Check for visible damage. Replace the damaged parts.

Check for running sounds. Replace the motor reductor.

Pulley bearings Check for slack. Refer to sec-

tion 9.6.

Replace the pulley. Refer to

section 9.7.

Photocells and reflectors Check for visible damage. Replace the photocell and the

reflector if necessary. Refer to

section 9.7.

Check for loose parts. Fasten loose parts.

Clean. Refer to section 9.3.

Cabling Make sure that all cables are

securely fastened.

Connect the cables again if

necessary.

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Check the oil level. Refill the oil.

Check the oil for contamination. Change the oil.

Check the air gap of the brake. Adjust the air gap.

All bolt connections Check all bolt connections. Tighten bolts using the correct

tool and torque.

1 Or after 10,000 running hours, whichever comes first.

Item Task Action when required by the

check

Motor reductor

Follow the instructions in the

manual of the manufacturer of

the motor reductor.

Change the oil.

Pulleys Replace the pulleys.

Loading...

Loading...