UM-PRORUNNER_Mk5-1.2-EN-US 33

Description

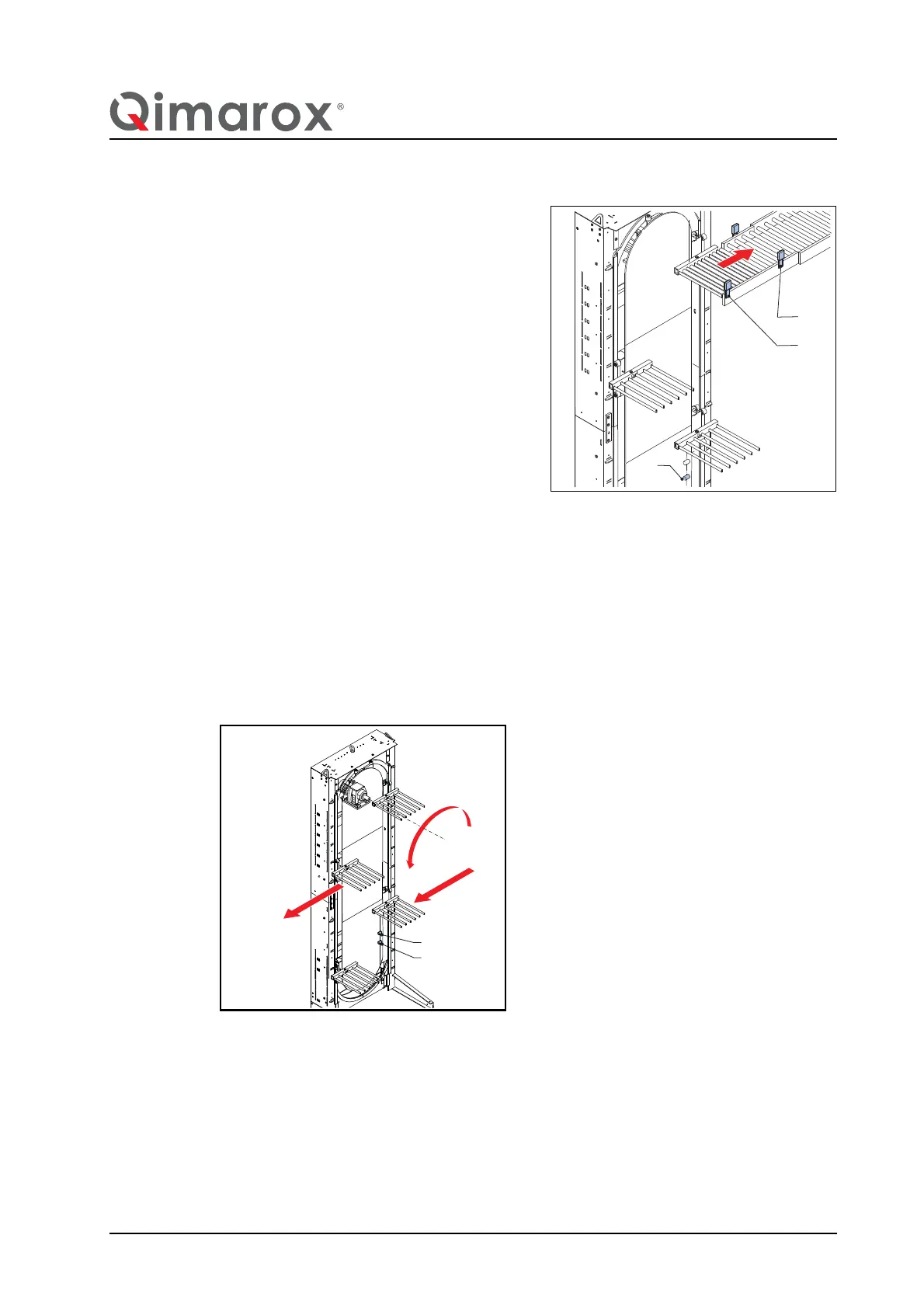

Monitoring of the passage of the product carrier

/i

Sensor B3 has been mounted into the

machine. This sensor is operated by each

product carrier in the circulating movement.

After this a time frame will start. At the end of

this time frame it is checked whether the

passage where the product carrier passes the

putting down position is free from product. This

is checked by sensors B8 and B9.

The distance between operation of sensor B3 and the putting down position must be

smaller than the space between the two consecutive product carriers. When products are

still present at the moment that the time frame ends, detected by sensors B8 and B9, the

machine drive must stop immediately. The drive may only start up again when these

positions have been reported empty for a certain period. Sensor B8 sets a flag when there

is a product on the outfeed. Sensor B9 resets the flag at a falling edge. If the flag is set

(true) the lift stops at the moment that the time frame expires.The lift can go on at the

moment that the flag is reset (false) again.

Signalling descending / ascending carrier

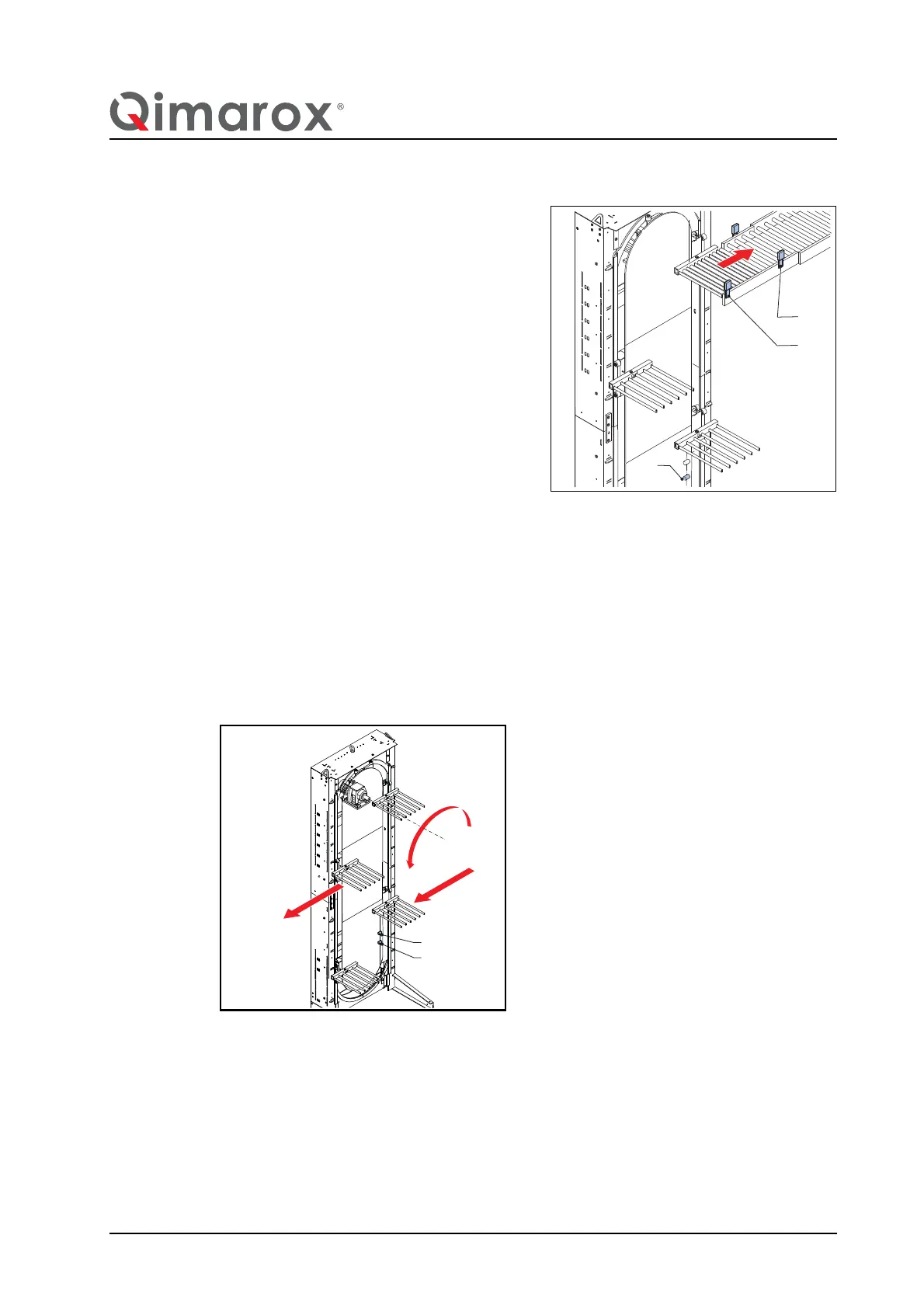

Fig. 1Ascending carrier

/i

The infeed conveyor is on the lower position

and the outfeed conveyor is on the higher

position. The products are transported from the

lower to the higher position.

B3 Start time frame sensor

B8 Sensor for checking presence of

product on the outfeed

B9 Sensor for checking if product has

left the outfeed (on falling edge)

B9

B8

B3

B1 Product release sensor

B3 Start time frame sensor

Loading...

Loading...