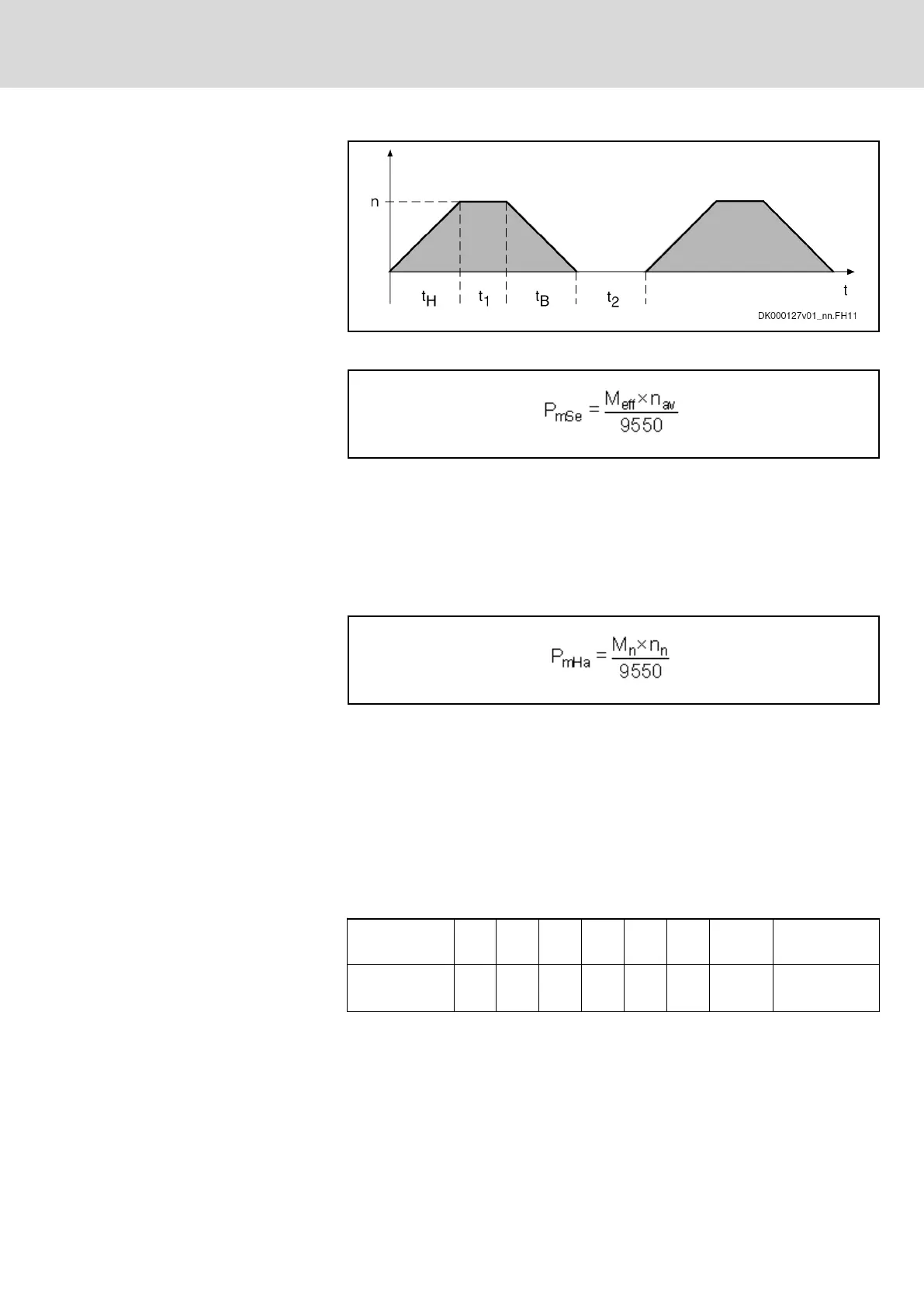

Fig.15-5: Average Speed; Effects of Run-Up and Braking Times Taken Into Ac‐

count

Mechanical Power for Servo

Drives

P

mSe

Mechanical continuous power for servo drives [kW]

M

rms

Effective motor torque [Nm]

n

av

Average motor speed [min

-1

]

Fig.15-6: Mechanical Power for Servo Drives

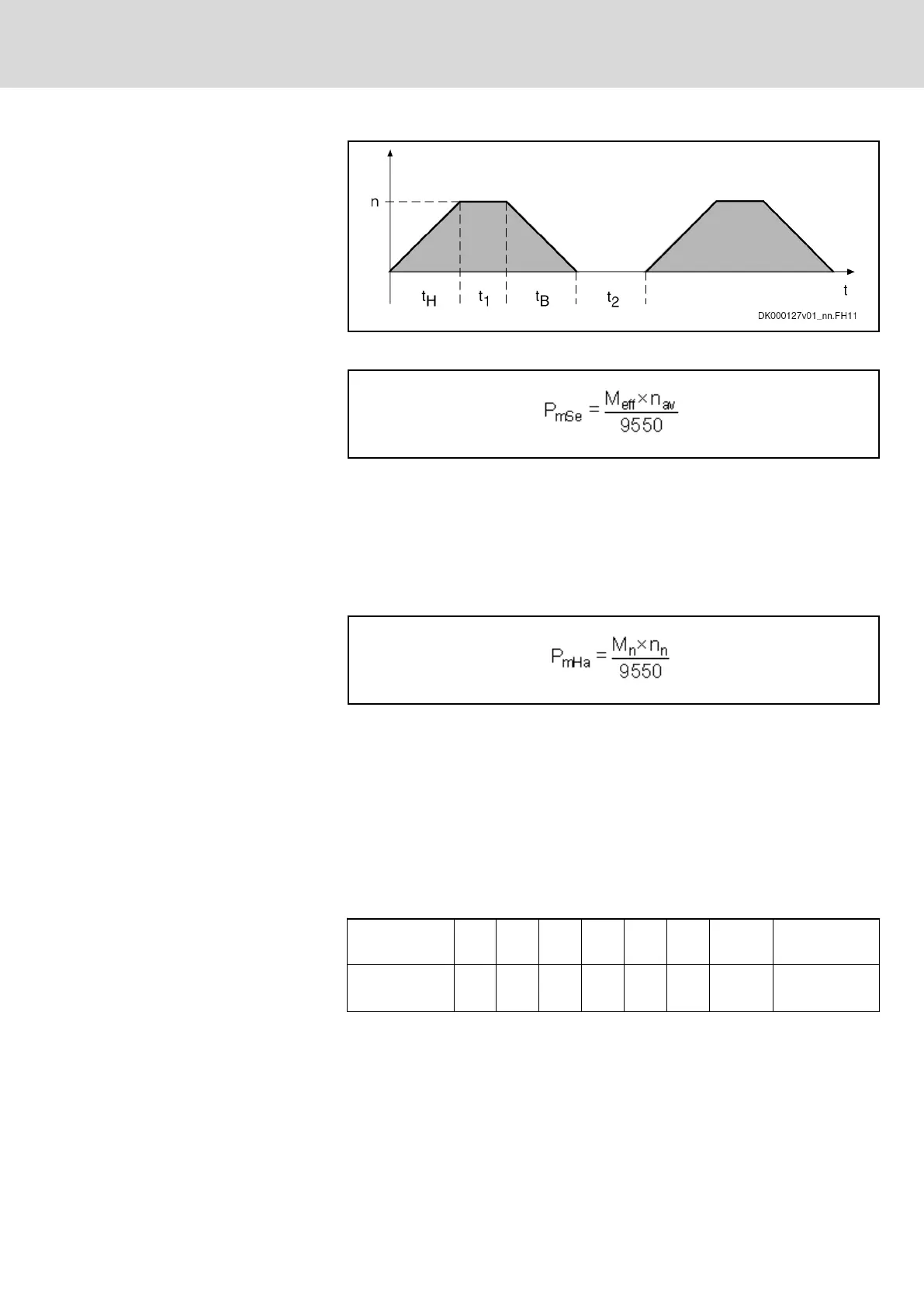

Mechanical Power for Main Drives

Main drives are drives which are mainly used in the constant power speed

range. Thus, nominal power is decisive for sizing the mains supply. The me‐

chanical nominal power of the main drives can be taken from the operating

characteristic or calculated from nominal speed and nominal torque.

P

mHa

Mechanical nominal power for main drives (shaft output) [kW]

M

n

Nominal motor torque [Nm]

n

n

Nominal motor speed [min

-1

]

Fig.15-7: Mechanical Power for Main Drives

DC Bus Continuous Power for

Servo Drives

The drive controller or the group of drive controllers has to make available the

DC bus power. However, in most applications, simultaneous loading of all

drives will not occur; thus, only the simultaneously occurring power must be

considered for calculating the DC bus continuous power to be made available

for servo drives. To calculate the DC bus continuous power to be made avail‐

able for typical NC feed axes at machine tools, inclusion of a so-called simul‐

taneity factor has proved to be favorable in practical application:

Number of ax‐

es

1 2 3 4 5 6 7 n = n + 1

Simultaneity

factor (F

G

)

1 1,15 1,32 1,75 2,0 2,25

F

G

=2,5 F

Gn

= F

G

+ 0,25

Tab.15-1: Simultaneity Factors

DOK-INDRV*-SYSTEM*****-PR06-EN-P

Rexroth IndraDrive Drive Systems with HMV01/02 HMS01/02, HMD01, HCS02/03

Bosch Rexroth AG 249/309

Calculations

Loading...

Loading...