Reference Manual Rev 1.13

004R-646-113 Page 13

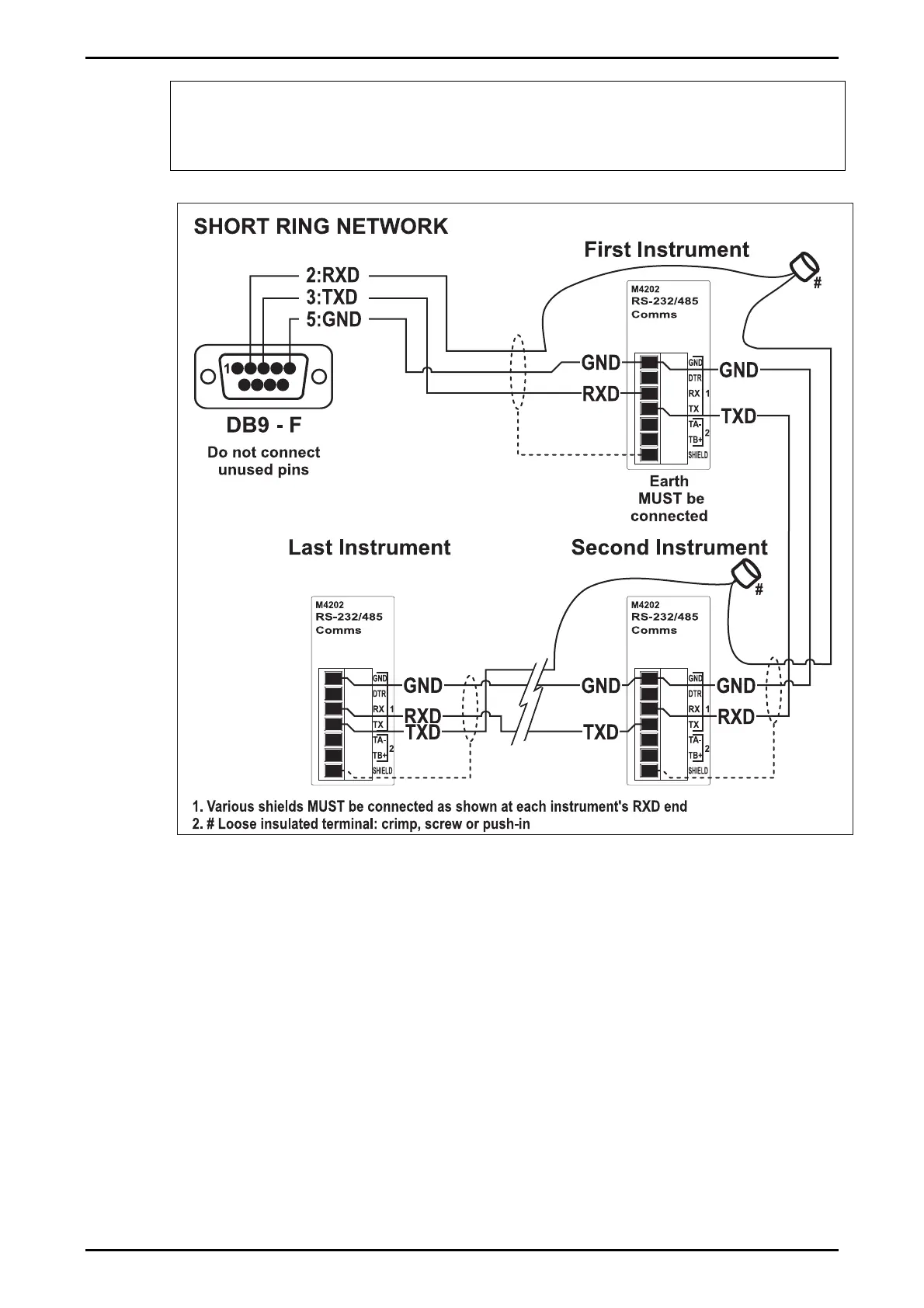

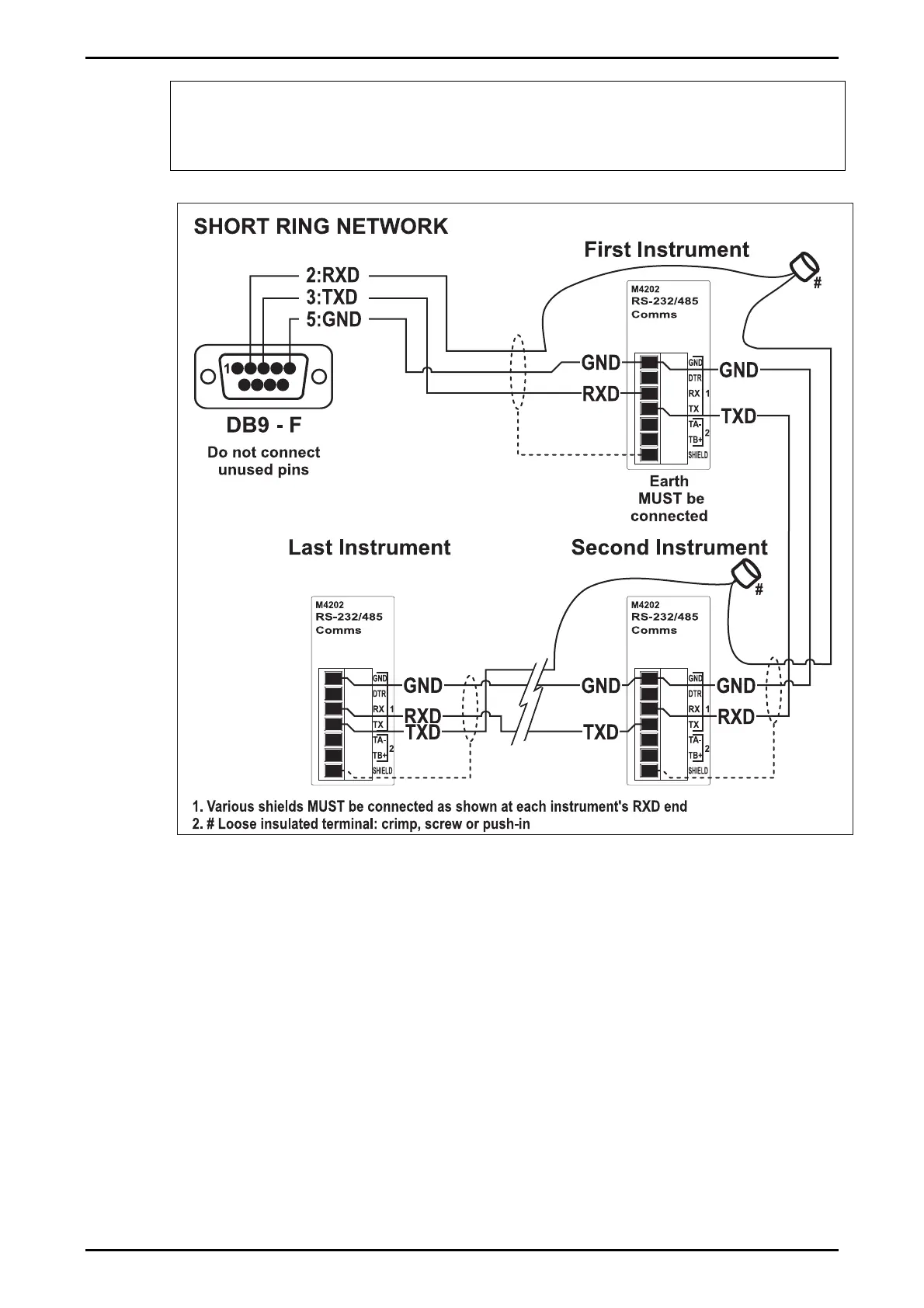

When operating in a Ring Network, the Instruments must have:

same serial port options, i.e., baud, parity, data bits, stop bits;

unique addresses.

Figure 7: RS-232 Short Cable Runs (Ring Network using COM Port)

Loading...

Loading...