Maintenance and meter exchange

FLOWSIC500 · Operating Instructions · 8025733/1GMJ/V4-2/2022-07 · © SICK Engineering GmbH 125

Subject to change without notice

7.4.10.1 Leak tightness check successful

7.4.10.2 Leak tightness check not successful

1 Remove the test cap with the socket

wrench.

2 Screw in the closure cap.

3 Then connect the replacement gas

flow meter to the electric system, see

§3. 4 “Electrical installation”.

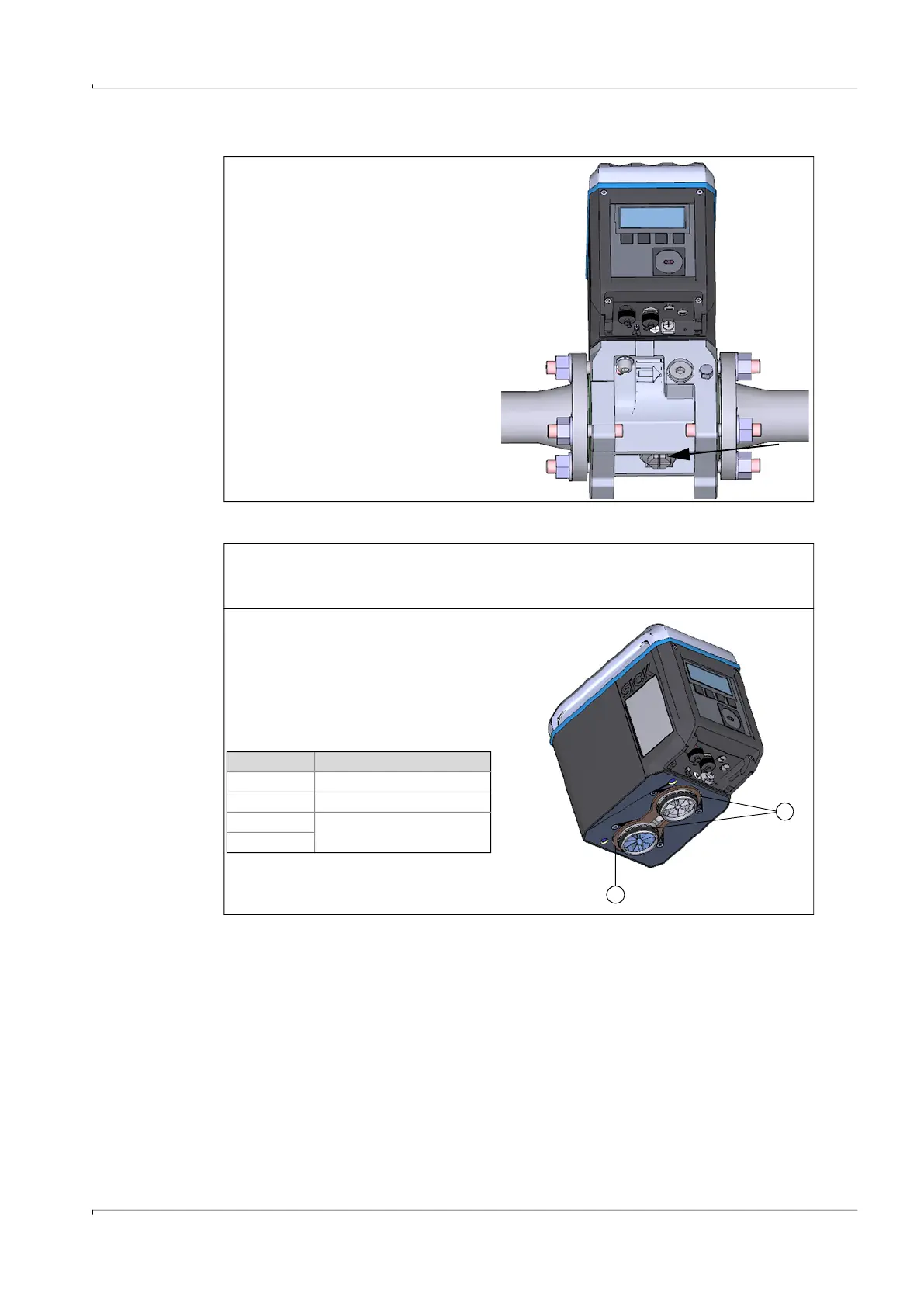

1 Close the line and depressurize the device.

2 Vent the environment.

3 Remove the gas flow meter from the adapter as described, see → p. 118, §7.4.8.

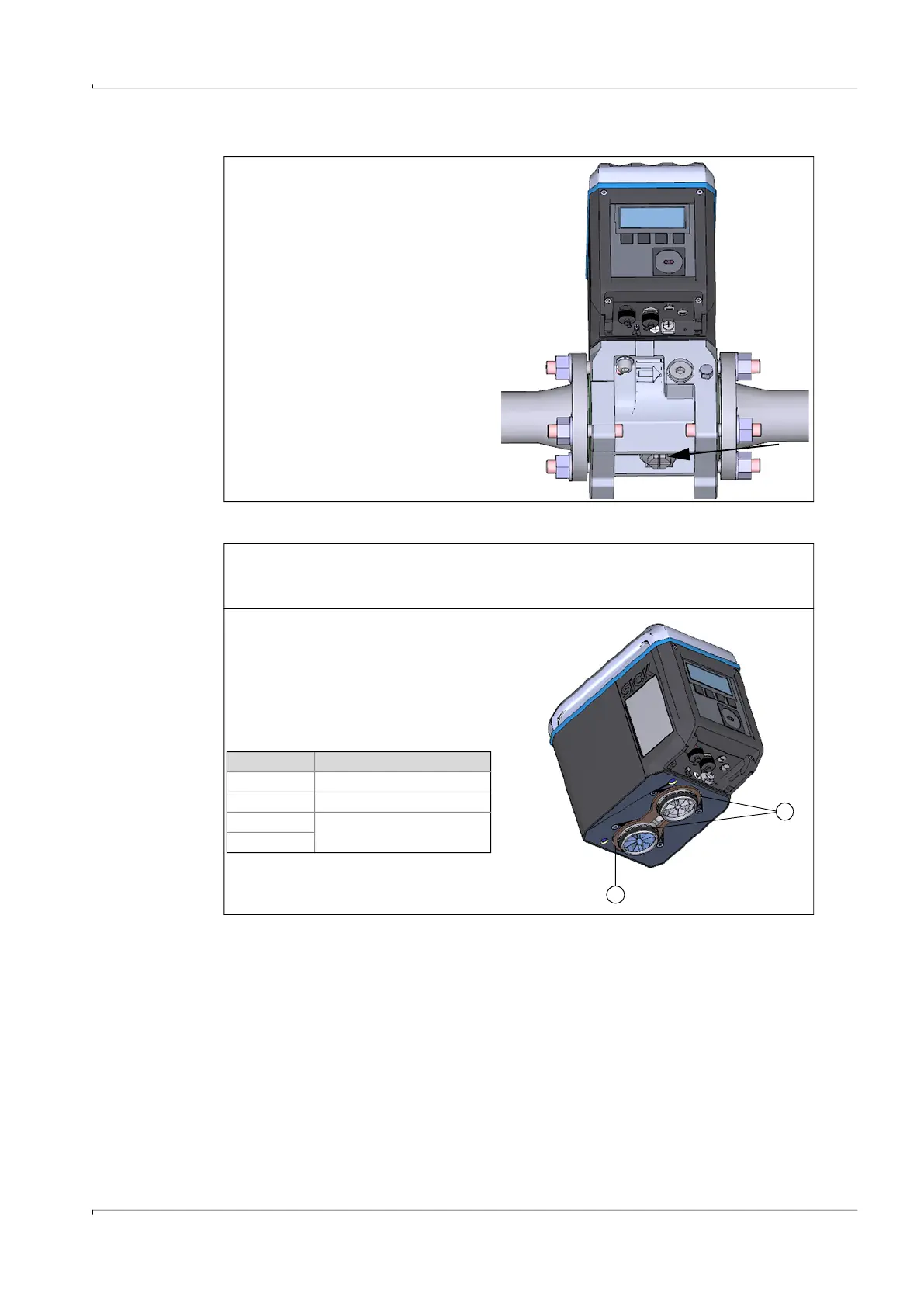

4 Check flat seal (1) and the O-rings on

connections pieces (2) for

completeness, intactness and

correct installation. When the sealing

elements are damaged, a new seal

set is available as spare part.

1

2

Meter size Item number

DN50 2067394

DN80 2067395

DN100

2067396

DN150

Loading...

Loading...