Conditions for determining the accuracy of the actual object position:

•

Web sheet in optimal object position

•

Fluctuation in read direction < ± 100 mm

•

Constant ambient temperature

Determining measurement accuracy for actual object position

1. Select characteristic for the distance between sender and receiver in the diagram.

Example: Characteristic "d" for 1,000 mm

2. Identify optimal object position. Example: 678.0 mm

3. Identify actual object position. The actual object position is the actual distance

between object and sender. Example: 648.0 mm

4. Calculate difference between the optimal object position and the real object posi‐

tion.

Example: 648.0 mm – 678.0 mm = –30 mm

5. Identify accuracy using the diagram.

Example: ± 0.48 mm

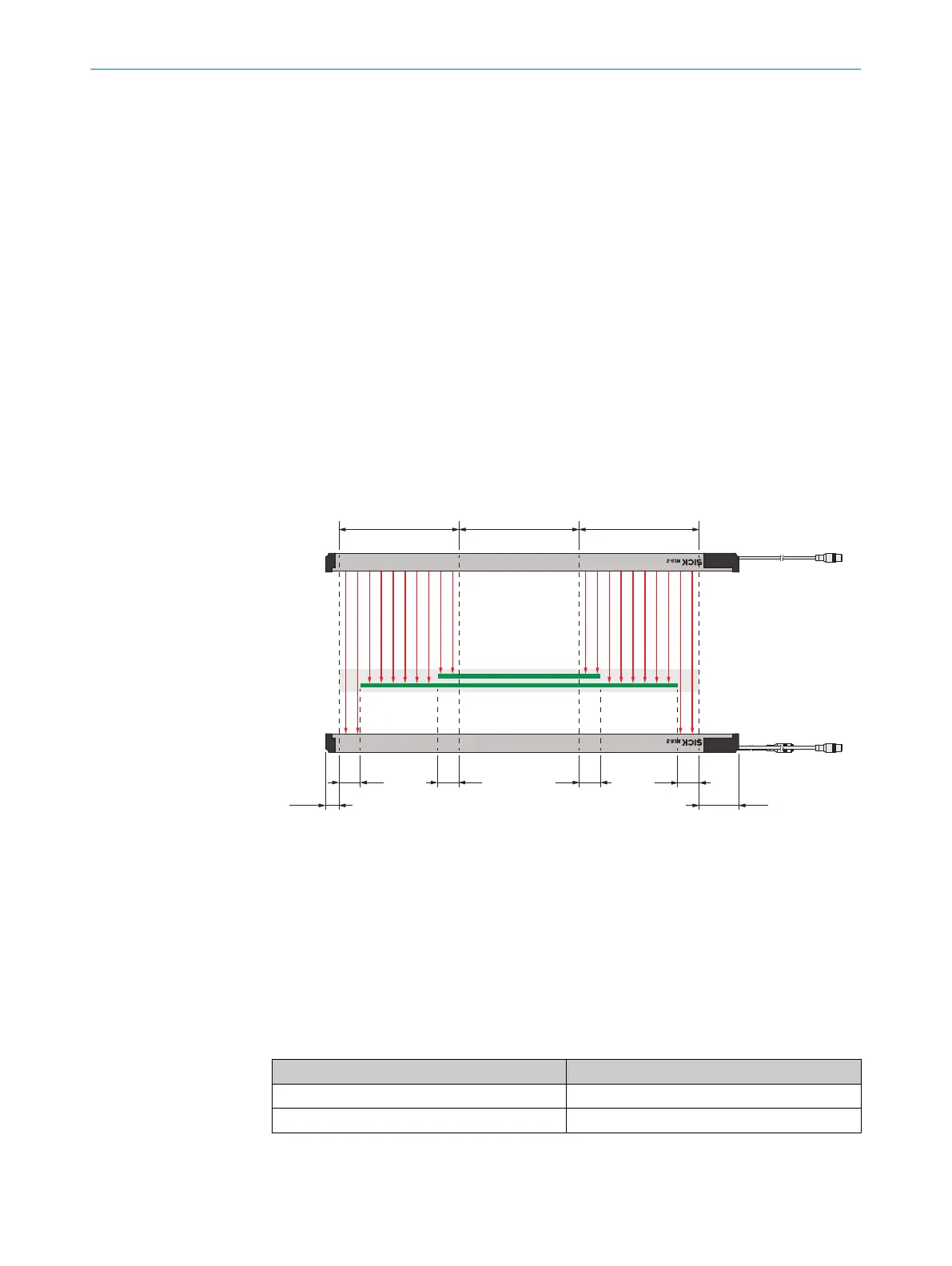

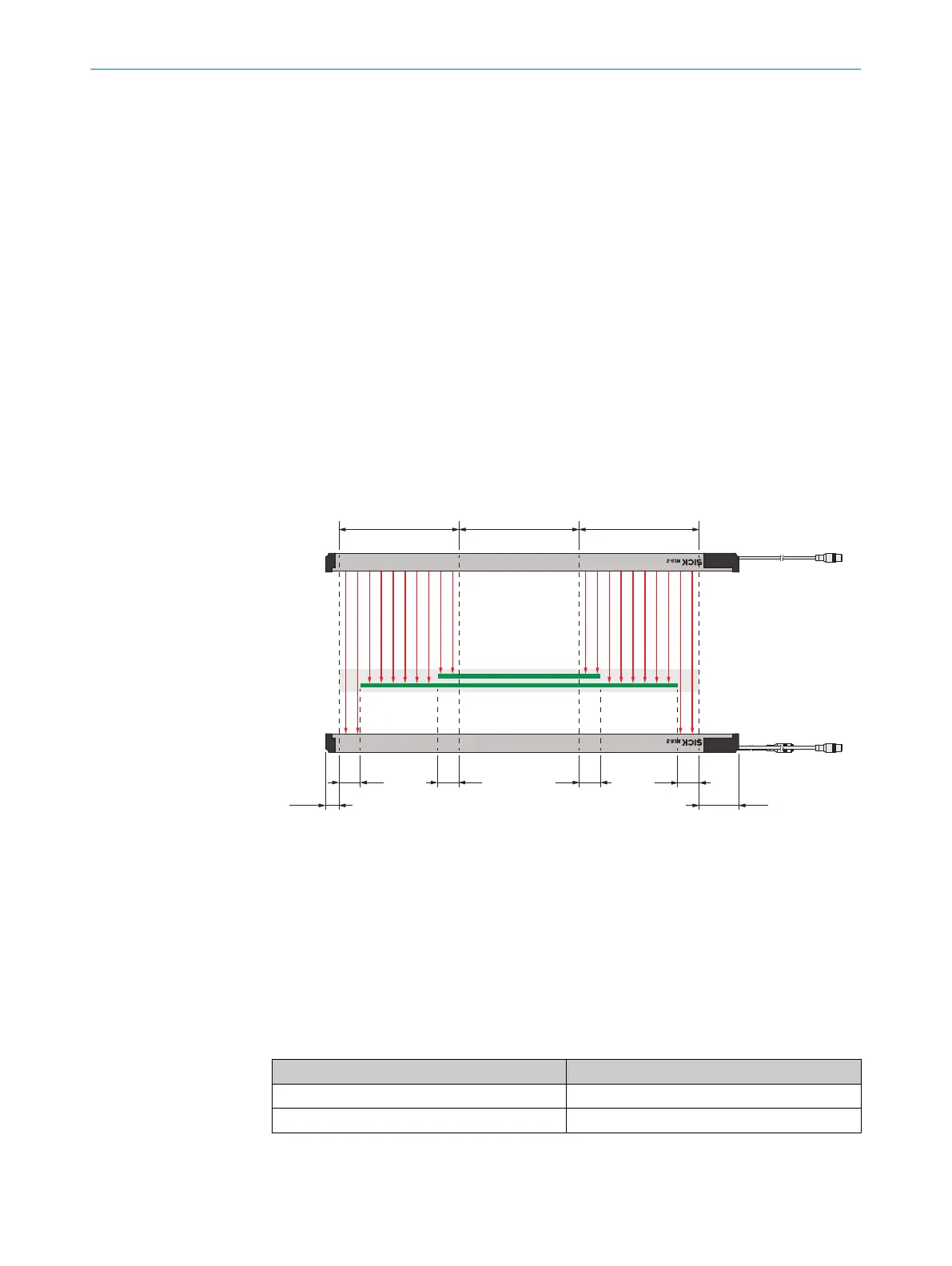

4.4 Required minimum distances for an object

You must comply with the following minimum distances for an object:

•

Measurement field border - edge

rs

min

max

4

5

3

1

2

A

62

8

13,5

A A A

6

7

Figure 18: Object widths (example of MLG-2 with empty modules)

1

Head side measurement modules

2

Empty modules

3

Connection side measurement modules

4

Minimal object width with empty modules arranged in the center

5

Maximum object width

6

A: Necessary distance between measurement field border - edge

7

Head side blind zone

8

Connection side blind zone

Table 10: Required distance A

Description Distance A (measurement field border - edge)

Typical distance 23 mm

Minimum distance under ideal conditions

1

8 mm

1

Ideal conditions: Homogeneous material, optimal ambient conditions and optimal object position

PLANNING 4

8024643/2019-09-02 | SICK O P E R A T I N G I N S T R U C T I O N | MLG-2 WebChecker

25

Subject to change without notice

Loading...

Loading...