This enables a coordinated maintenance sequence.

The maintenance sequence is documented and can be tracked.

Maintenance is initiated and edited in the faceplate in the "Maintenance" view

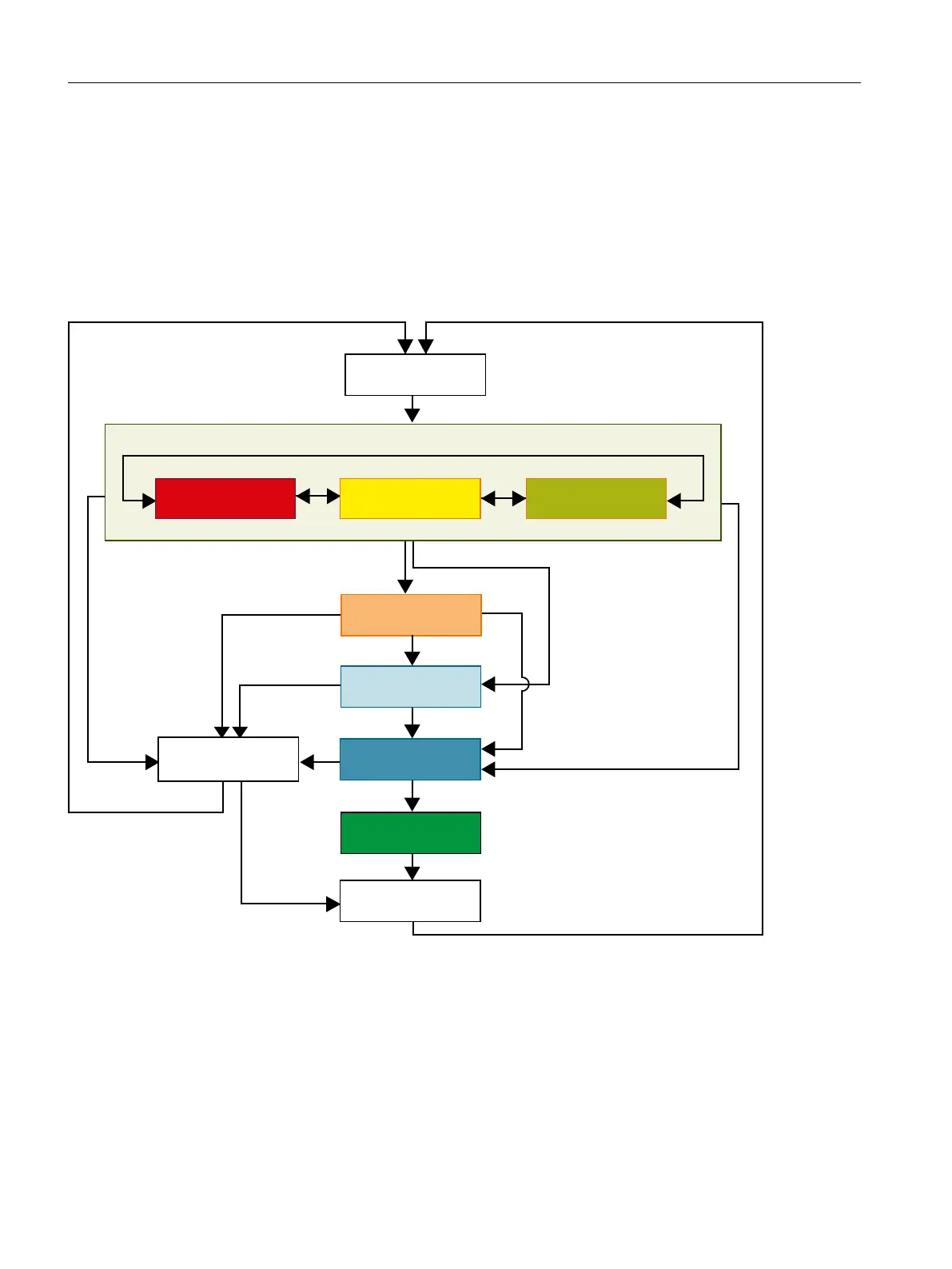

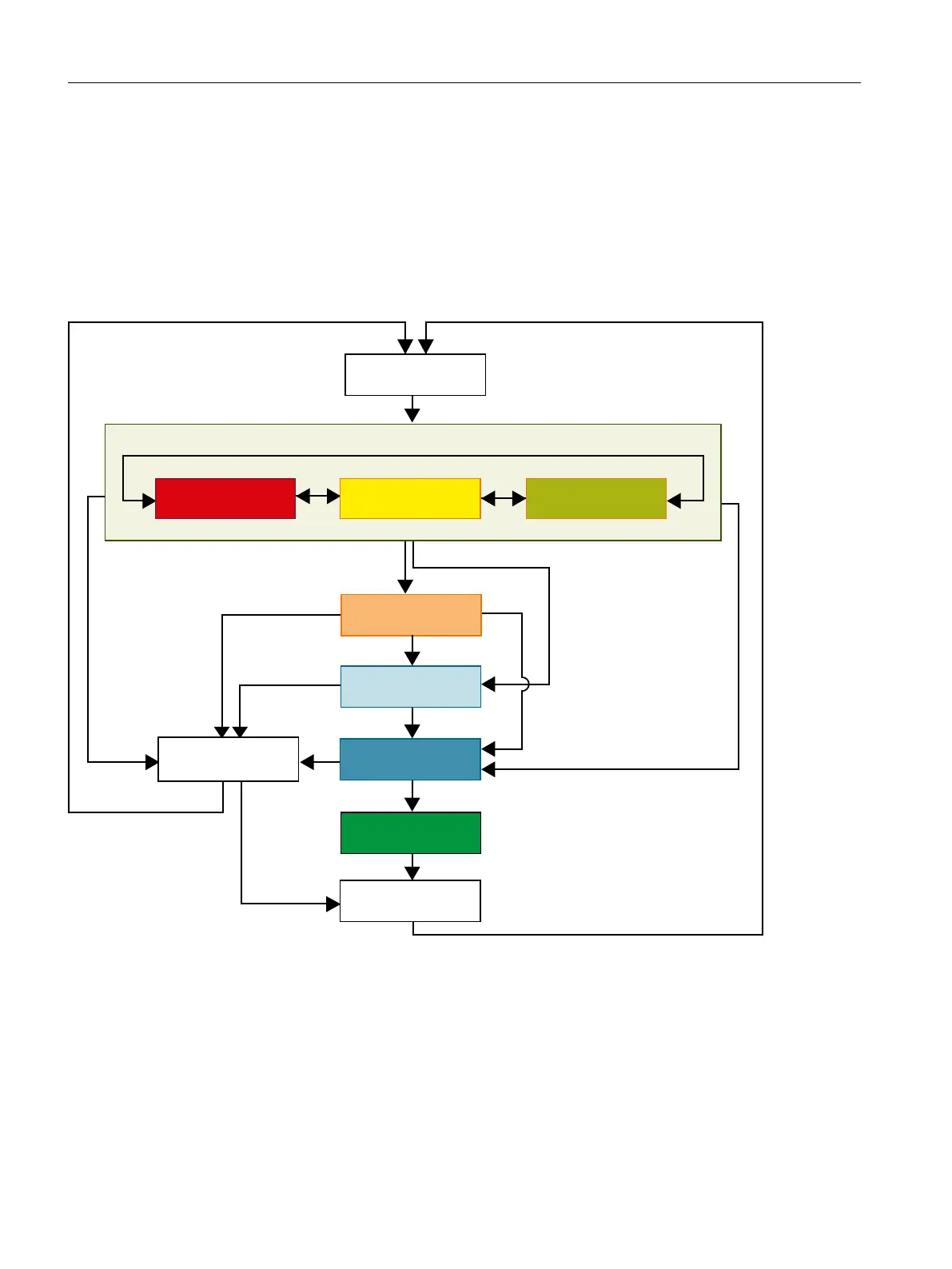

Status diagram

The possible status transitions are explained in the diagram below.

0DLQWHQDQFHDODUP

,QVHUYLFH

0DLQWHQDQFHUHTXLUHG

0DLQWHQDQFH

GHPDQGHG

&RPSOHWHG

&DQFHO

3ODQQHGVHUYLFLQJ

5HOHDVHUHTXHVW

*RRG

1RUPDOVWDWXV

Actions of the maintenance engineer cause status changes.

The next section provides detailed instructions for activating and deactivating a maintenance

job.

Additional information

You can find additional information on the release for maintenance and on configuring the

technological blocks in the online help

Process Control System PCS 7; Advanced Process

Library

.

Operator control and monitoring

6.13 Overview of maintenance

Maintenance Station

190 Function Manual, 03/2016, A5E36187641-AA

Loading...

Loading...