Programming and Operating Manual (Milling)

110 6FC5398-4DP10-0BA1, 01/2014

In block N10, the starting conditions are assigned to the corresponding arithmetic parameters. The calculation of the

coordinates in X and Z and the processing takes place in N20.

In block N30, R1 is incremented by the clearance angle R3, and R4 is decremented by 1.

If R4 > 0, N20 is executed again; otherwise, N50 with End of program.

Jump destination for program jumps

Functionality

A

or a

serve to mark blocks as jump destinations for program jumps. Program jumps can be used to

branch to the program sequence.

Labels can be freely selected, but must contain a minimum of 2 and a maximum of 8 letters or numbers of which the

first two

characters must be letters

or underscore characters.

Labels that are in the block that serves as the jump destination are

. They are always at the start of a block.

If a block number is also present, the label is located

.

Labels must be unique within a program.

;LABEL1 is the label, jump destination

;TR789 is the label, jump destination

- No block number existing

;Block number can be jump target

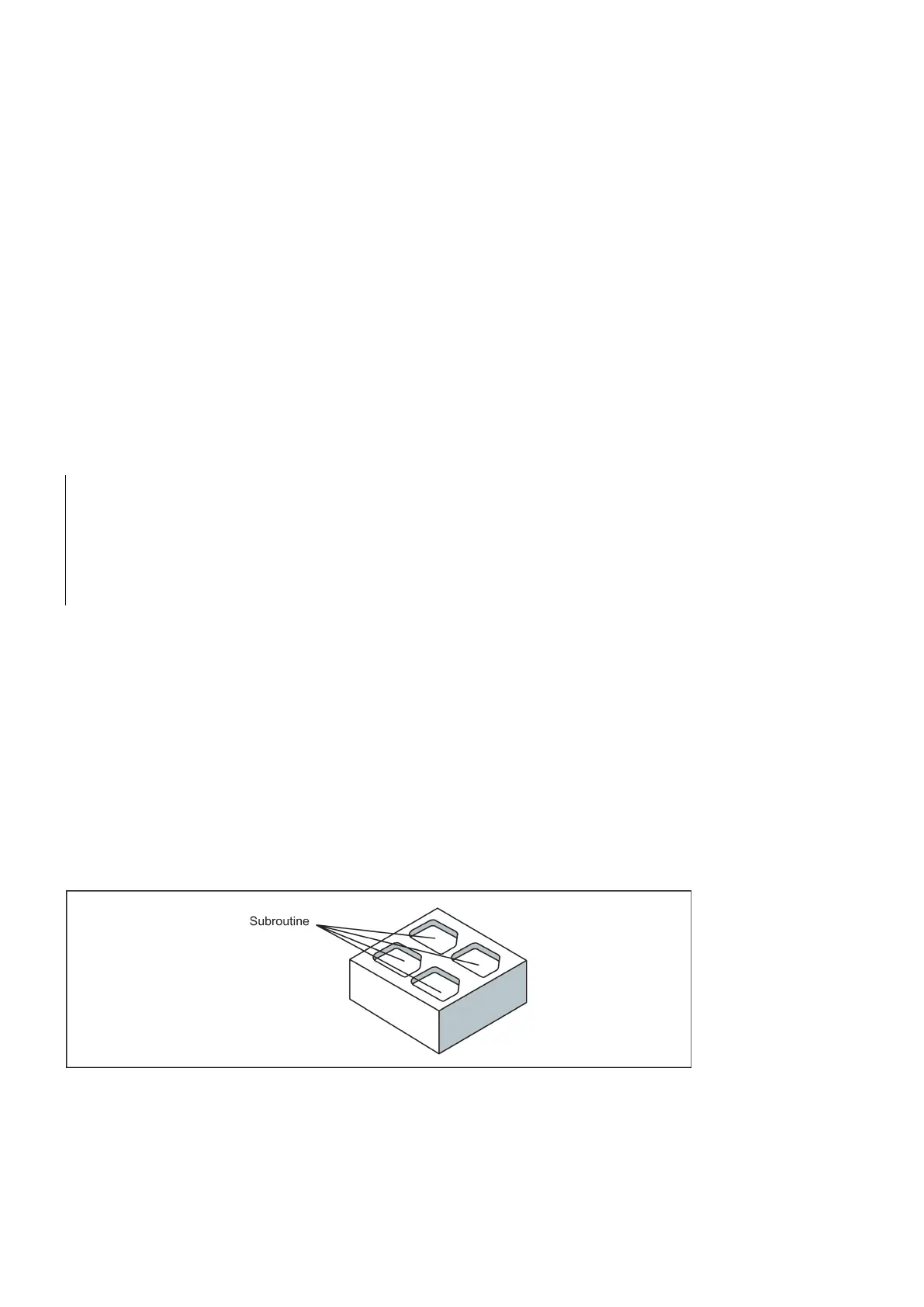

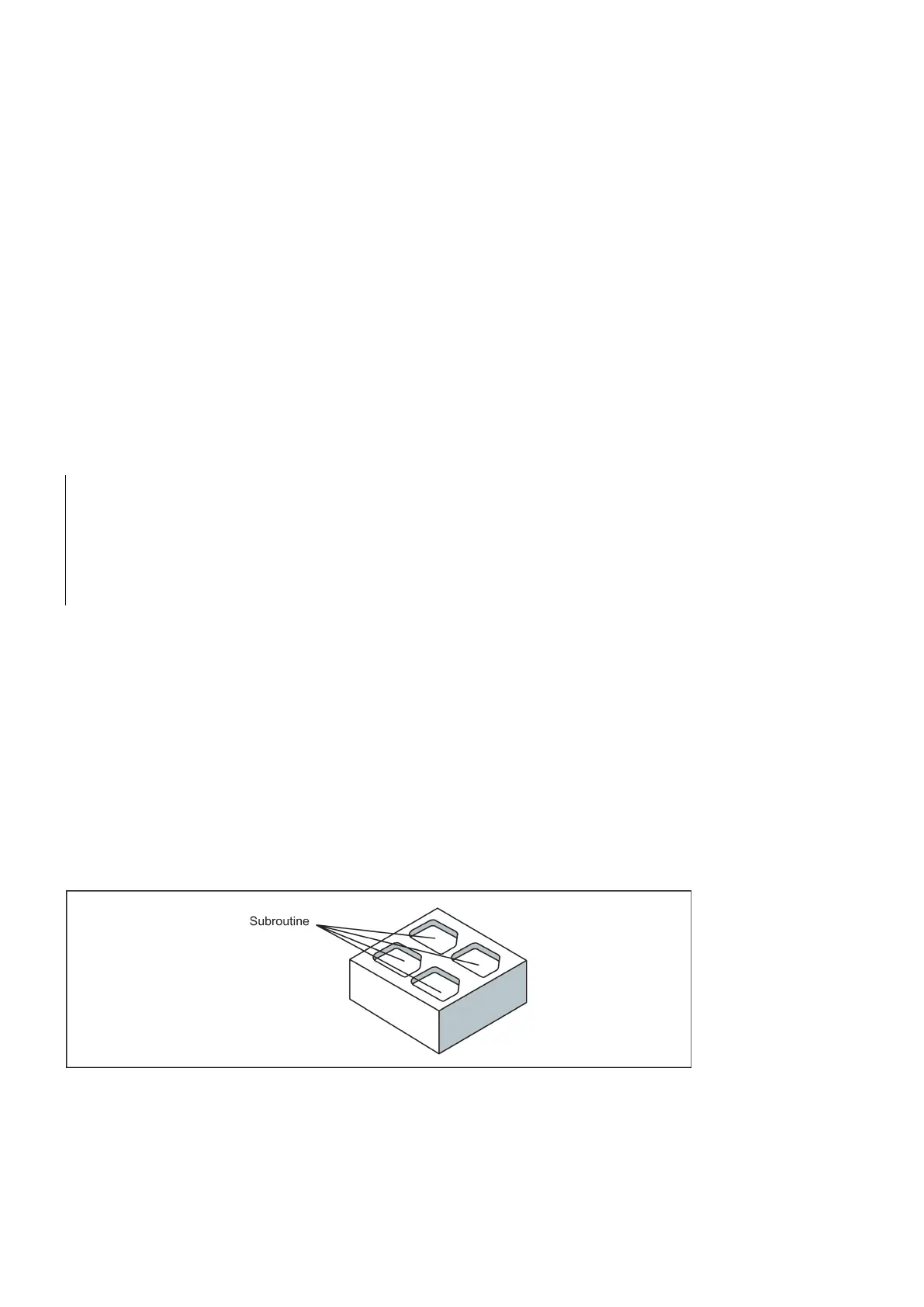

Subroutine technique

8.15.1

General information

Application

Basically, there is no difference between a main program and a subroutine.

Frequently recurring machining sequences are stored in subroutines, e.g. certain contour shapes. These subroutines are

called at the appropriate locations in the main program and then executed.

One form of a subroutine is the

. The machining cycles contain generally valid machining cases (e.g. drilling,

tapping, groove cutting, etc.). By assigning values via included transfer parameters, you can adapt the subroutine to your

specific application.

See the following illustration for example for using a subroutine for a workpiece four times:

Loading...

Loading...