Programming and Operating Manual (Milling)

192 6FC5398-4DP10-0BA1, 01/2014

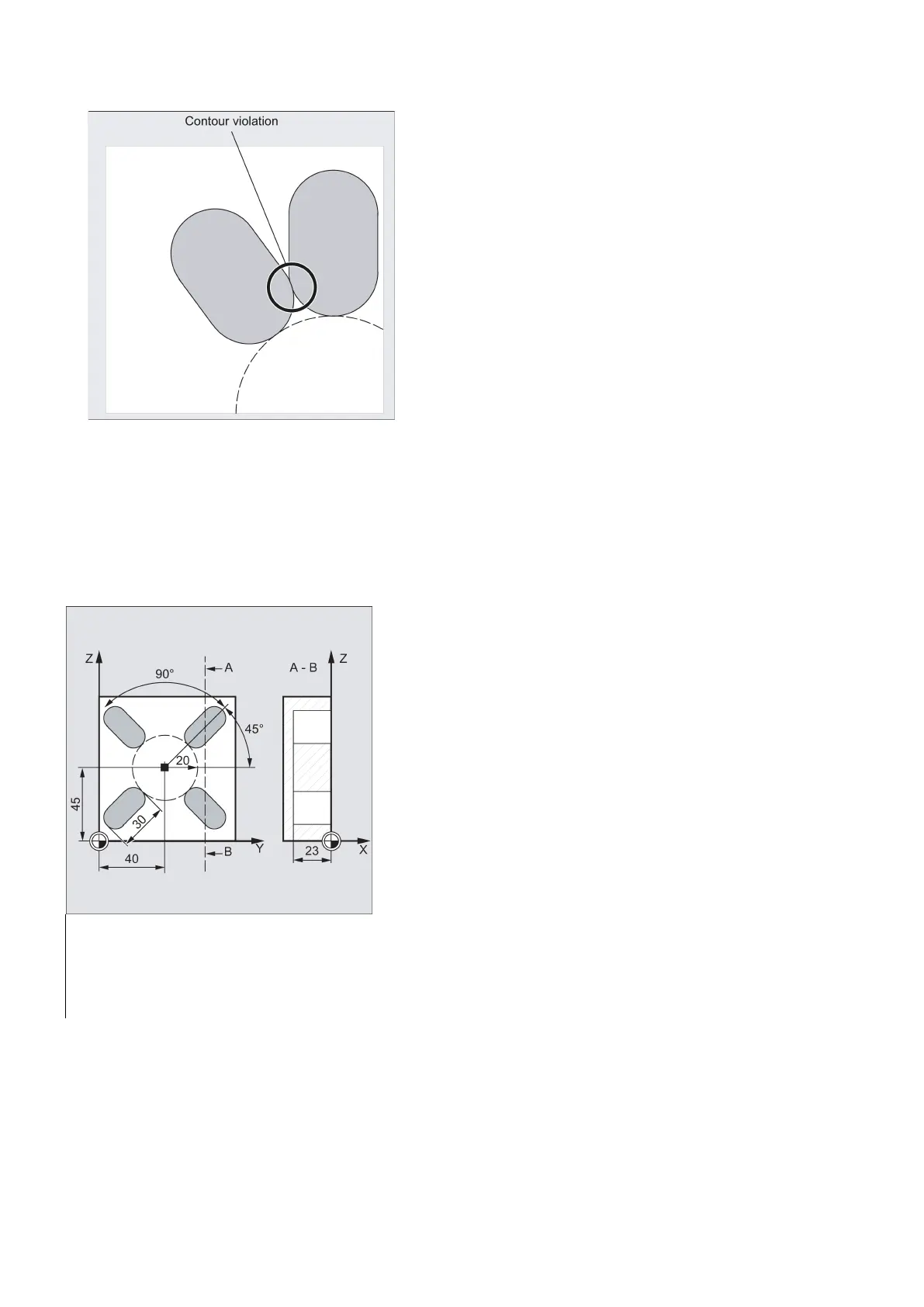

Programming example: Grooves

Four slots are milled.

The slots have the following dimensions: Length 30 mm, width 15 mm and depth 23 mm. The safety clearance is 1 mm, the

final machining allowance is 0.5 mm, the milling direction is G2, the maximum infeed in the depth is 6 mm.

The slot is to be machined completely. Infeed during finishing is to be performed directly to the pocket depth and the same

feedrate and speed are to be used.

See the following programming example for grooves:

N10 G17 G90 T1 D1 S600 M3

; Specification of technology values

; Approach starting position

N30 SLOT1(5, 0, 1, -23, , 4, 30, 15, 40, 45, 20, 45, 90,

100, 320, 6, 2, 0.5, 0, , 0, )

; Cycle call, VARI, MIDF, FFP2 and SSF

Circumferential slot - SLOT2

Programming

SLOT2 (RTP, RFP, SDIS, DP, DPR, NUM, AFSL, WID, CPA, CPO, RAD, STA1, INDA, FFD, FFP1, MID, CDIR, FAL, VARI,

MIDF, FFP2, SSF, FFCP)

Loading...

Loading...