Programming and Operating Manual (Milling)

210 6FC5398-4DP10-0BA1, 01/2014

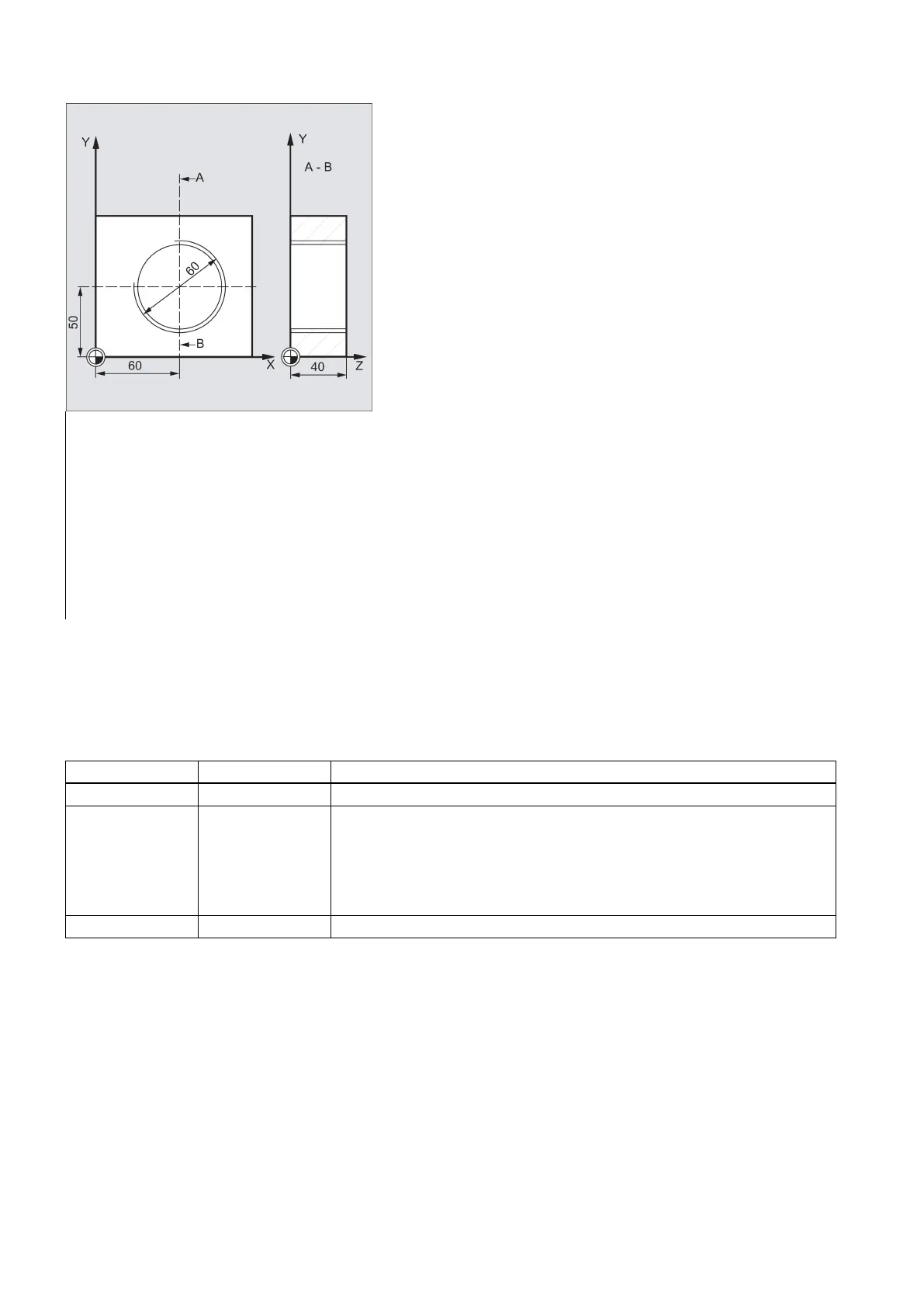

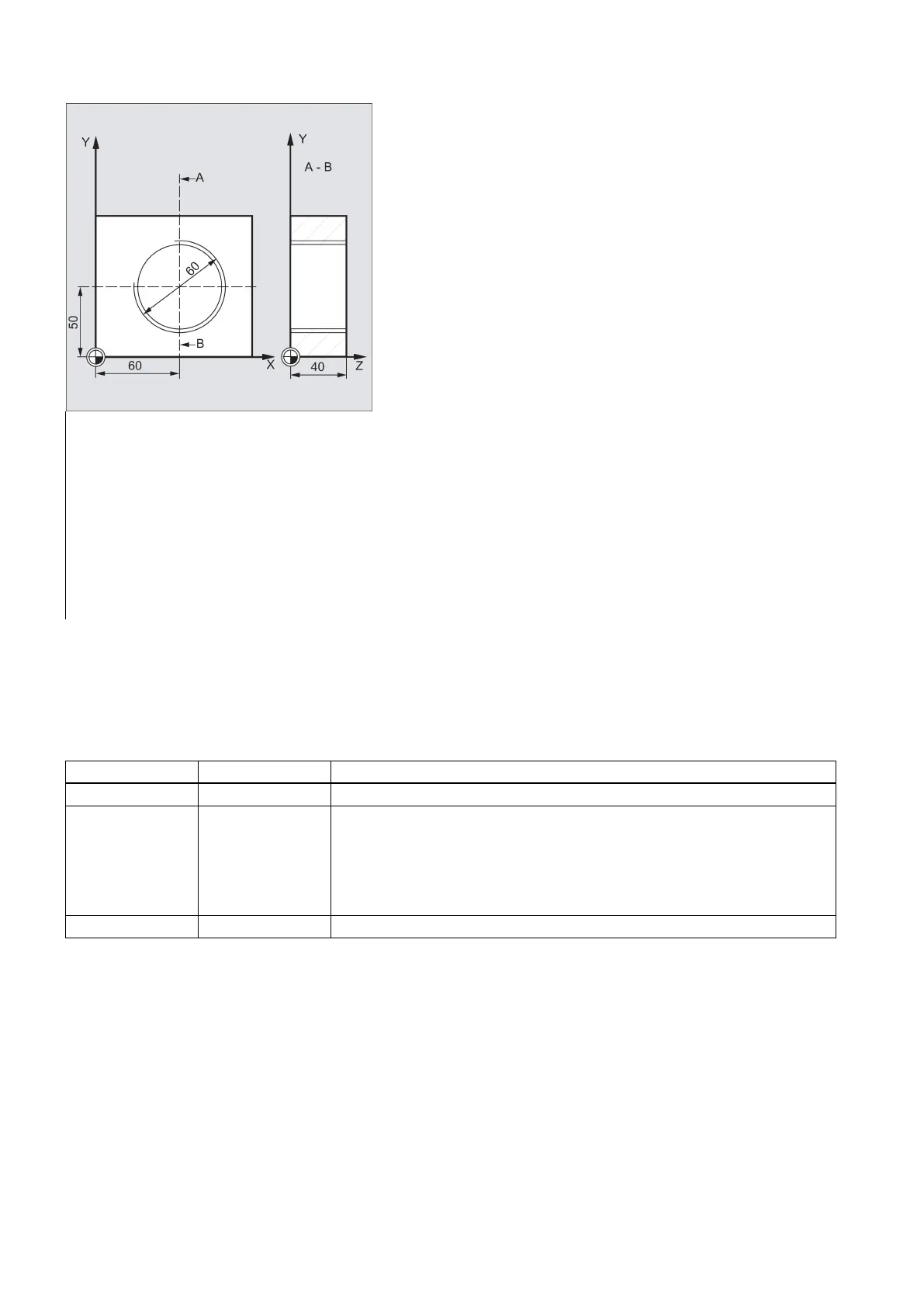

DEF REAL RTP=48, RFP=40, SDIS=5, DP=0, DPR=40, DIATH=60,

KDIAM=50

DEF REAL PIT=2, FFR=500, CPA=60,CPO=50

; Definition of the variable with value

assignments

N10 G90 G0 G17 X0 Y0 Z80 S200 M3

; Approach starting position

; Specification of technology values

N30 CYCLE90 (RTP, RFP, SDIS, DP, DPR, DIATH, KDIAM, PIT,

FFR, CDIR, TYPTH, CPA, CPO)

; Cycle call

; Approach position after cycle

High speed settings - CYCLE832

Programming

CYCLE832 (TOL, TOLM, 1)

TOL REAL Tolerance of machining axes

TOLM INT Machining type selection

0: Deselect

1: Finishing

2: Semi-finishing

3: Roughing

PSYS INT Internal parameter, only the default value 1 is possible

Use CYCLE832 to machine free-form surfaces that involve high requirements for velocity, precision and surface quality.

This cycle function groups together the important G codes, machine data and setting data that are required for high-speed

cutting machining.

Explanation of the parameters

TOL (Tolerance)

This refers to the tolerance of axes involved in machining. The tolerance value is written to the relevant machine or setting

data depending on the G codes.

Loading...

Loading...