Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA1, 01/2014

53

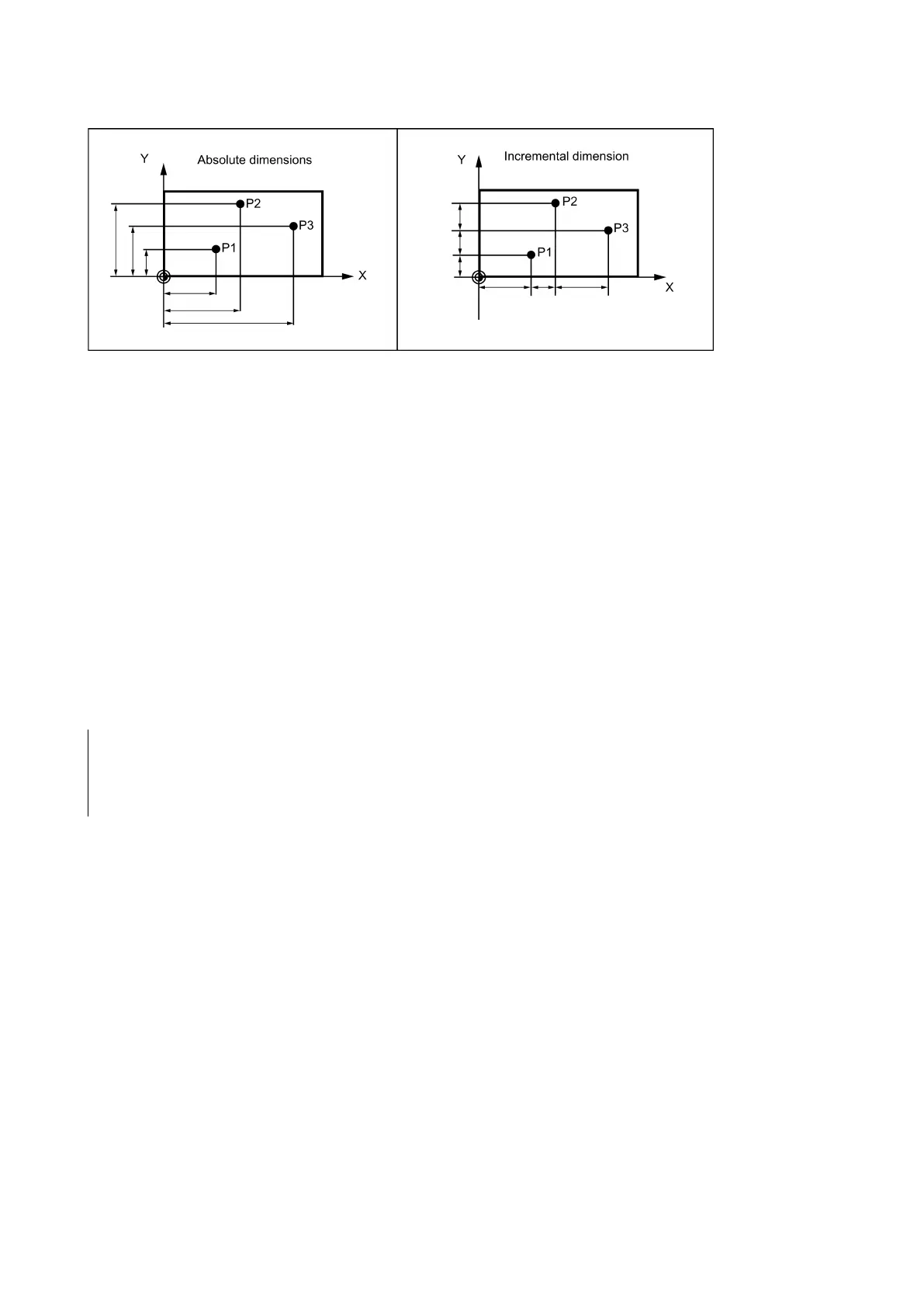

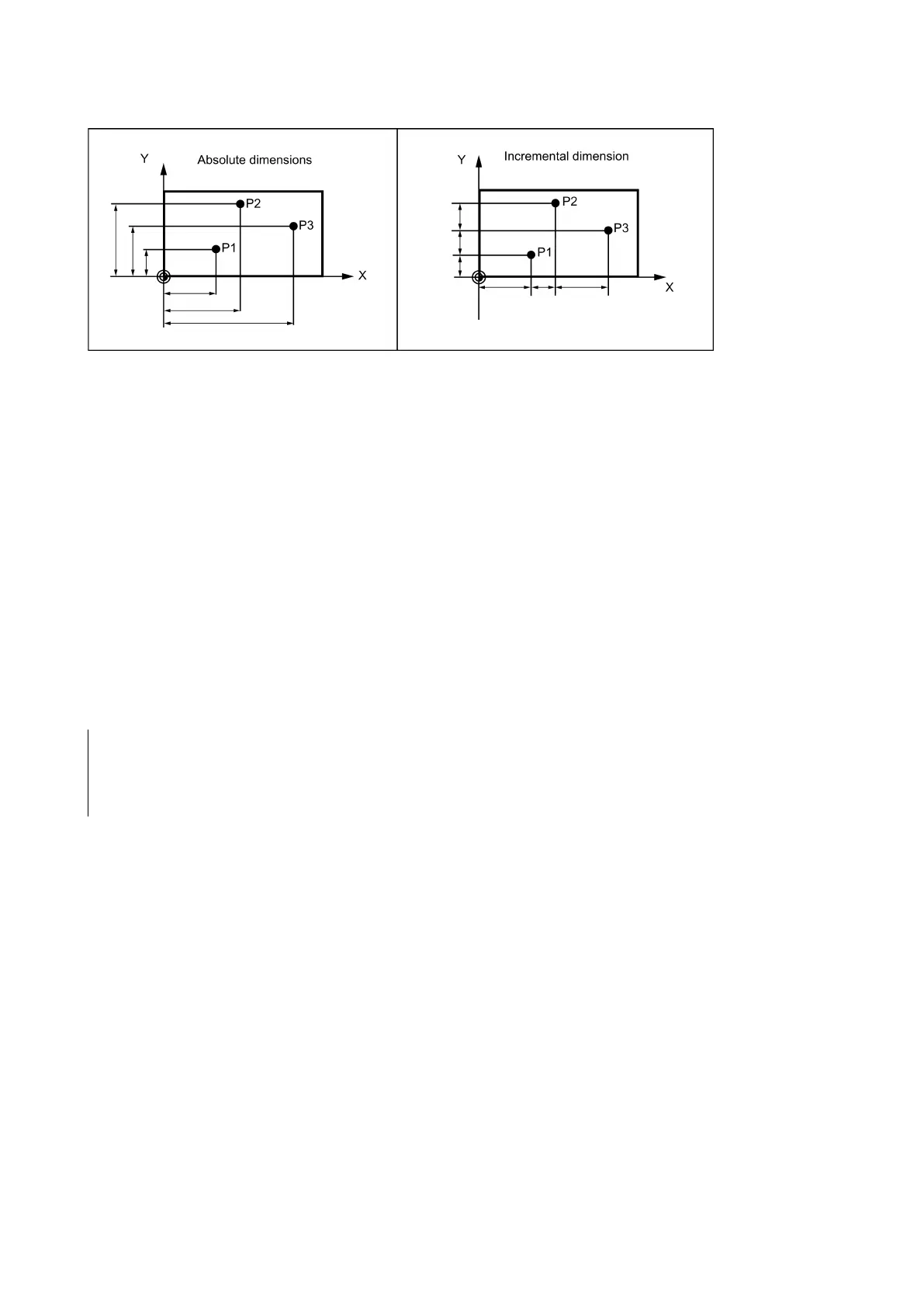

See the following illustration for different dimensioning types in the drawing:

Absolute dimensioning G90

With absolute dimensioning, the dimensioning data refers to the

zero of the coordinate system currently active

(workpiece

or current workpiece coordinate system or machine coordinate system). This is dependent on which offsets are currently

active: programmable, settable, or no offsets.

Upon program start, G90 is active for

and remains active until it is deselected in a subsequent block by G91

(incremental dimensioning data) (modally active).

Incremental dimensioning G91

With incremental dimensioning, the numerical value of the path information corresponds to the

axis path to be traversed

.

The leading sign indicates the

.

G91 applies to all axes and can be deselected in a subsequent block via G90 (absolute dimensioning).

Specification with =AC(...), =IC(...)

After the end point coordinate, write an equality sign. The value must be specified in round brackets.

Absolute dimensions are also possible for circle center points using =AC(...). Otherwise, the reference point for the circle

center is the circle starting point.

; X-dimensions remain absolute, incremental Z dimension

; Switch-over to incremental dimensioning

; X-remains incremental dimensioning, Z-absolute

Dimensions in metric units and inches: G71, G70, G710, G700

Functionality

If workpiece dimensions that deviate from the base system settings of the control system are present (inch or mm), the

dimensions can be entered directly in the program. The required conversion into the base system is performed by the control

system.

G70 ; Inch dimensions

G71 ' Metric dimensions

G700 ; Inch dimensions, also for feedrate F

G710 ; Metric dimensions, also for feedrate F

Loading...

Loading...