Programming and Operating Manual (Milling)

86 6FC5398-4DP10-0BA1, 01/2014

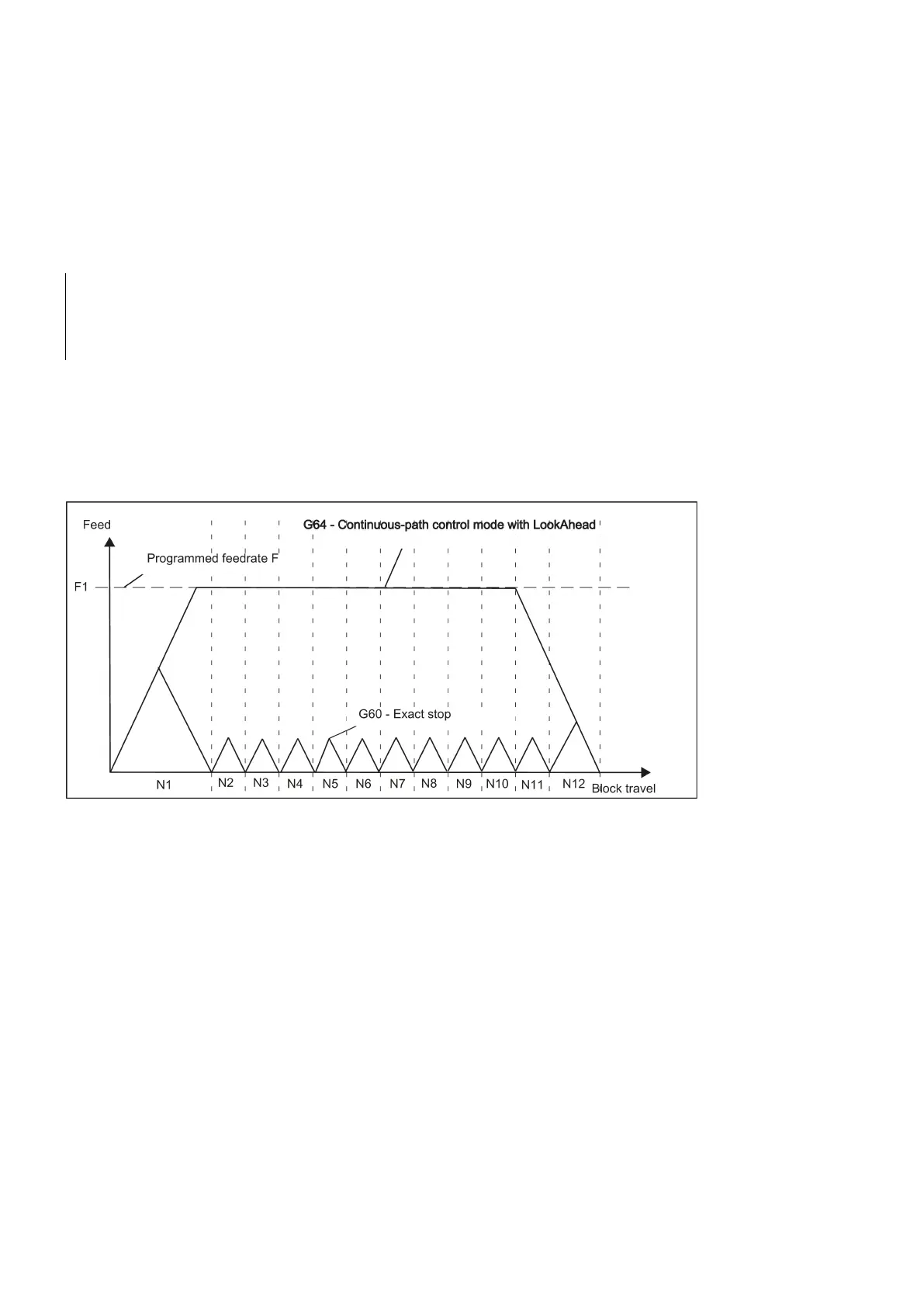

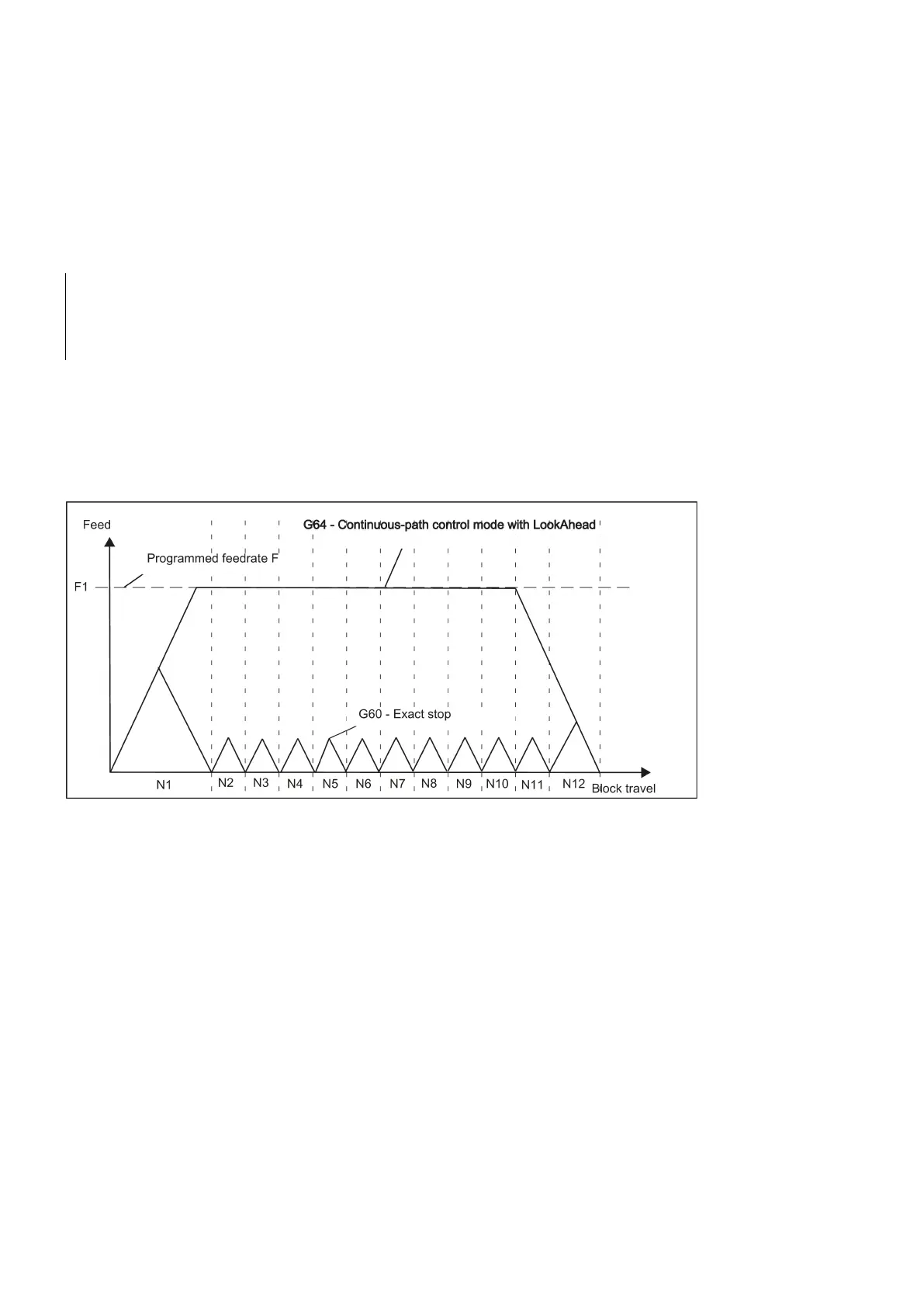

Continuous-path control mode G64

The objective of the continuous-path control mode is to avoid deceleration at the block boundaries and to switch

with

a path velocity as constant as possible

(in the case of tangential transitions). The function works with

look-ahead

velocity control

over several blocks.

For non-tangential transitions (corners), the velocity can be reduced rapidly enough so that the axes are subject to a

relatively high velocity change over a short period of time. This may lead to a significant jerk (acceleration change). The size

of the jerk can be limited by activating the SOFT function.

; Continuous-path control mode continues to be active

; Switching over to exact stop

Look-ahead velocity control:

In the continuous-path control mode with G64, the control system determines the velocity control for several NC blocks in

advance automatically. This enables acceleration and deceleration across multiple blocks with approximately tangential

transitions. For paths that consist of short travels in the NC blocks, higher velocities can be achieved than without look

ahead.

See the following illustration for comparison of the G60 and G64 velocity behavior:

Dwell time: G4

Functionality

Between two NC blocks, you can interrupt the machining for a defined time by inserting a

with G4; e.g. for

relief cutting.

The words with F... or S... are only used in this block for the specified time. Any previously programmed feedrate F or a

spindle speed S remain valid.

G4 F... ; Dwell time in seconds

G4 S... ; Dwell time in spindle revolutions

Loading...

Loading...