Programming and Operating Manual (Milling)

162 6FC5398-4DP10-0BA1, 01/2014

The center point coordinates for the milling pattern or the pocket to be machined are programmed in a rectangular

coordinate system.

The G functions active prior to the cycle call and the current programmable frame remain active beyond the cycle.

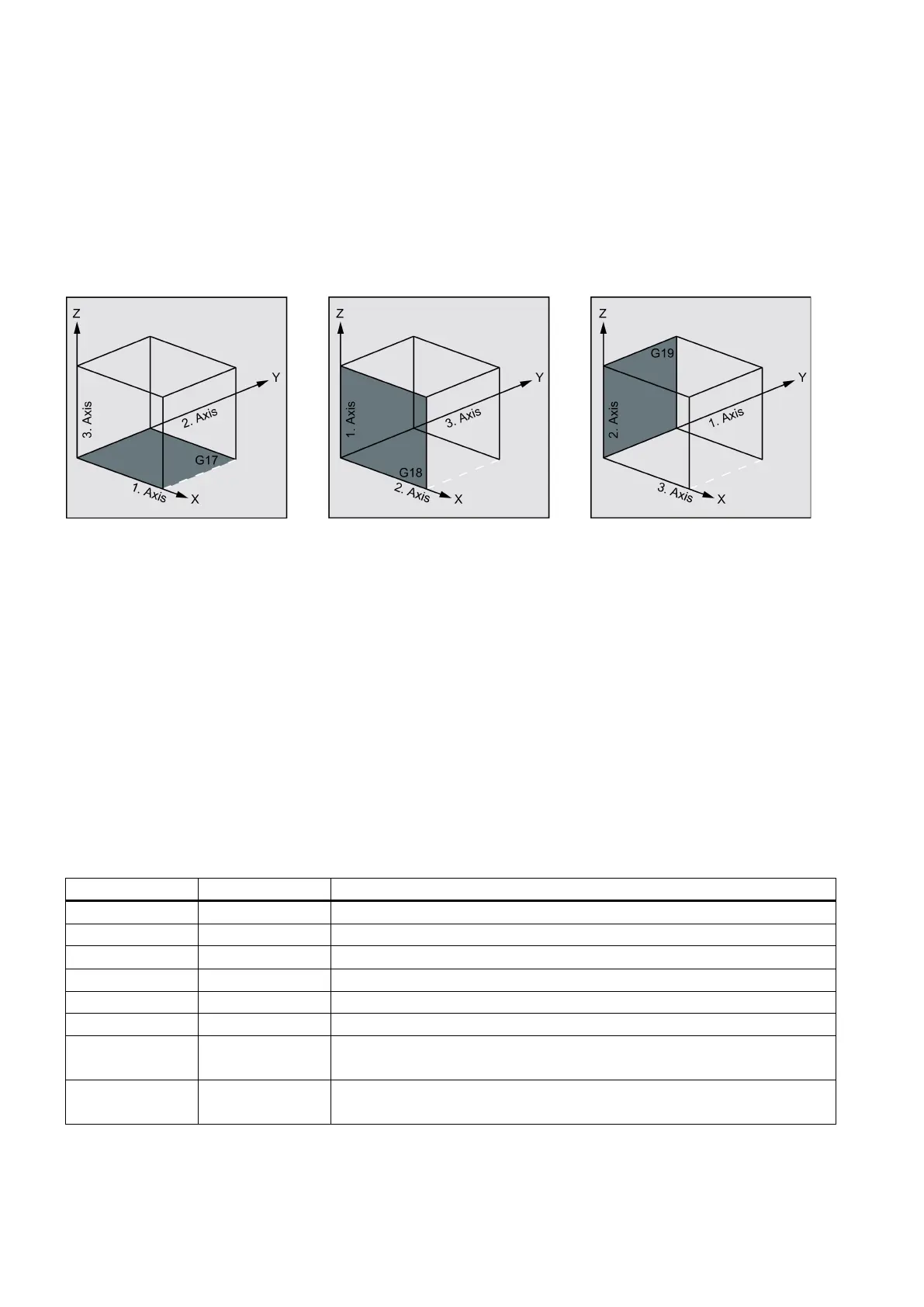

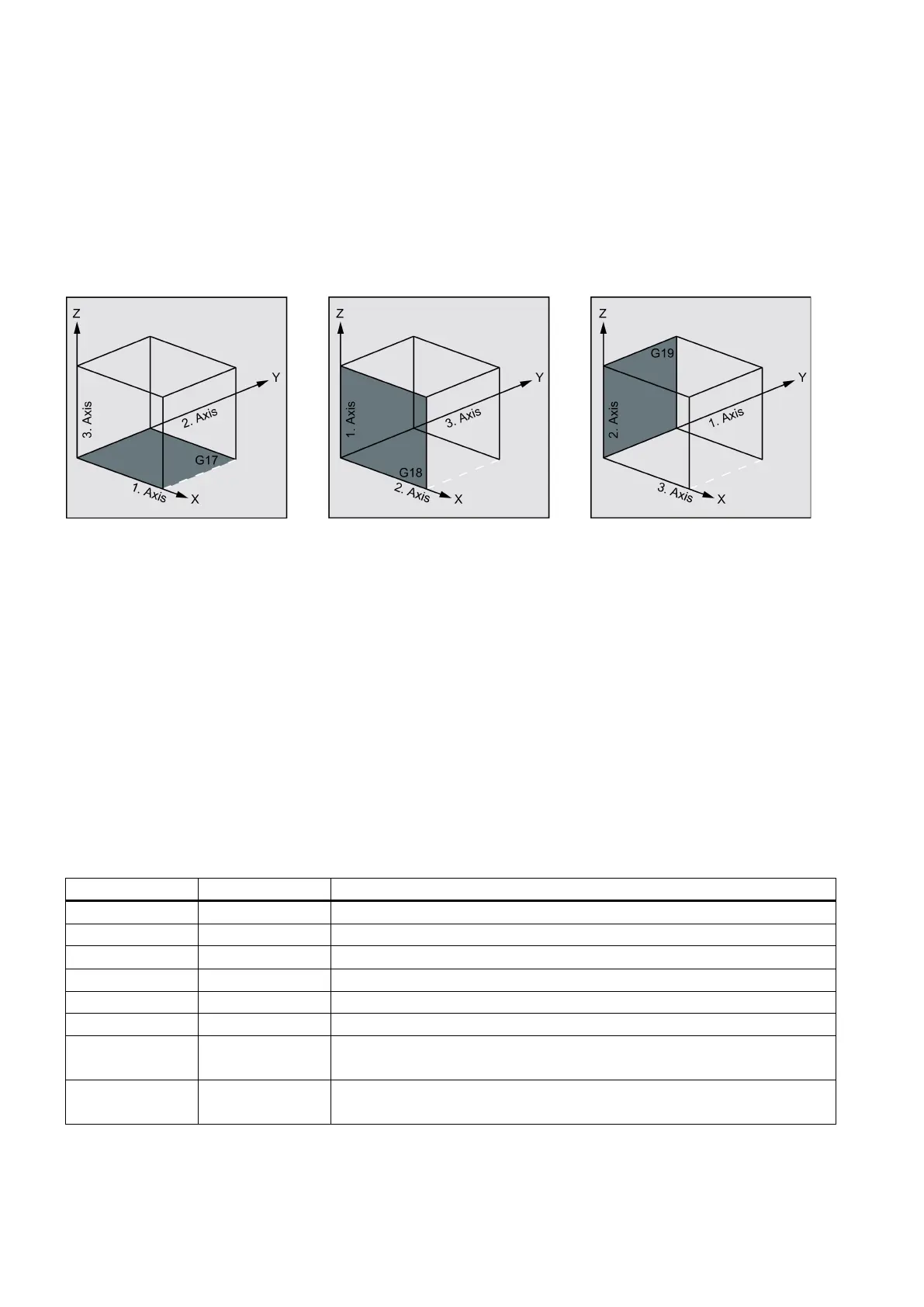

Milling cycles generally assume that the current workpiece coordinate system has been defined by selecting a plane (G17,

G18 or G19) and activating a programmable frame (if necessary). The infeed axis is always the third axis of this coordinate

system.

See the following illustration for plane and axis assignment:

Messages with regard to the machining state

During the execution of the milling cycles, various messages that refer to the machining status are displayed on the screen.

The following messages are possible:

● "Elongated hole <No.>(first figure) being machined"

● "Slot <No.>(other figure) being machined"

● "Circumferential slot <No.>(last figure) being machined"

In each case, <No.> stands for the number of the figure that is currently being machined.

These message do not interrupt the program execution and continue to be displayed until the next message is displayed or

the cycle is completed.

Face milling - CYCLE71

Programming

CYCLE71 (_RTP, _RFP, _SDIS, _DP, _PA, _PO, _LENG, _WID, _STA, _MID, _MIDA, _FDP, _FALD, _FFP1, _VARI, _FDP1)

_RTP REAL Retraction plane (absolute)

_RFP REAL Reference plane (absolute)

_SDIS REAL Safety clearance (to be added to the reference plane; enter without sign)

_DP REAL Depth (absolute)

_PA REAL Starting point (absolute), first axis of the plane

_PO REAL Starting point (absolute), second axis of the plane

_LENG REAL Rectangle length along the first axis, incremental.

The corner from which the dimension starts results from the sign.

_WID REAL Rectangle length along the second axis, incremental.

The corner from which the dimension starts results from the sign.

Loading...

Loading...