Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA1, 01/2014

163

_STA REAL Angle between the longitudinal axis of the rectangle and the first axis of the

plane (abscissa, enter without sign).

Range of values: 0° ≤ STA < 180°

_MID REAL Maximum infeed depth (enter without sign)

_MIDA REAL Maximum infeed width during solid machining in the plane as a value (enter

without sign)

_FDP REAL Retraction travel in the finishing direction (incremental, enter without sign)

_FALD REAL Finishing dimension in the depth (incremental, enter without sign)

_FFP1 REAL Feedrate for surface machining

_VARI INT Machining type (enter without sign)

UNITS DIGIT

Values: 1 roughing, 2 finishing

TENS DIGIT:

Values:

1: parallel to the first axis of the plane, in one direction,

2: parallel to the second axis of the plane, in one direction,

3: parallel to the first axis of the plane, with alternating direction

4: parallel to the second axis of the plane, with alternating direction

_FDP1 REAL Overrun travel in the direction of the plane infeed (incremental, enter without

sign)

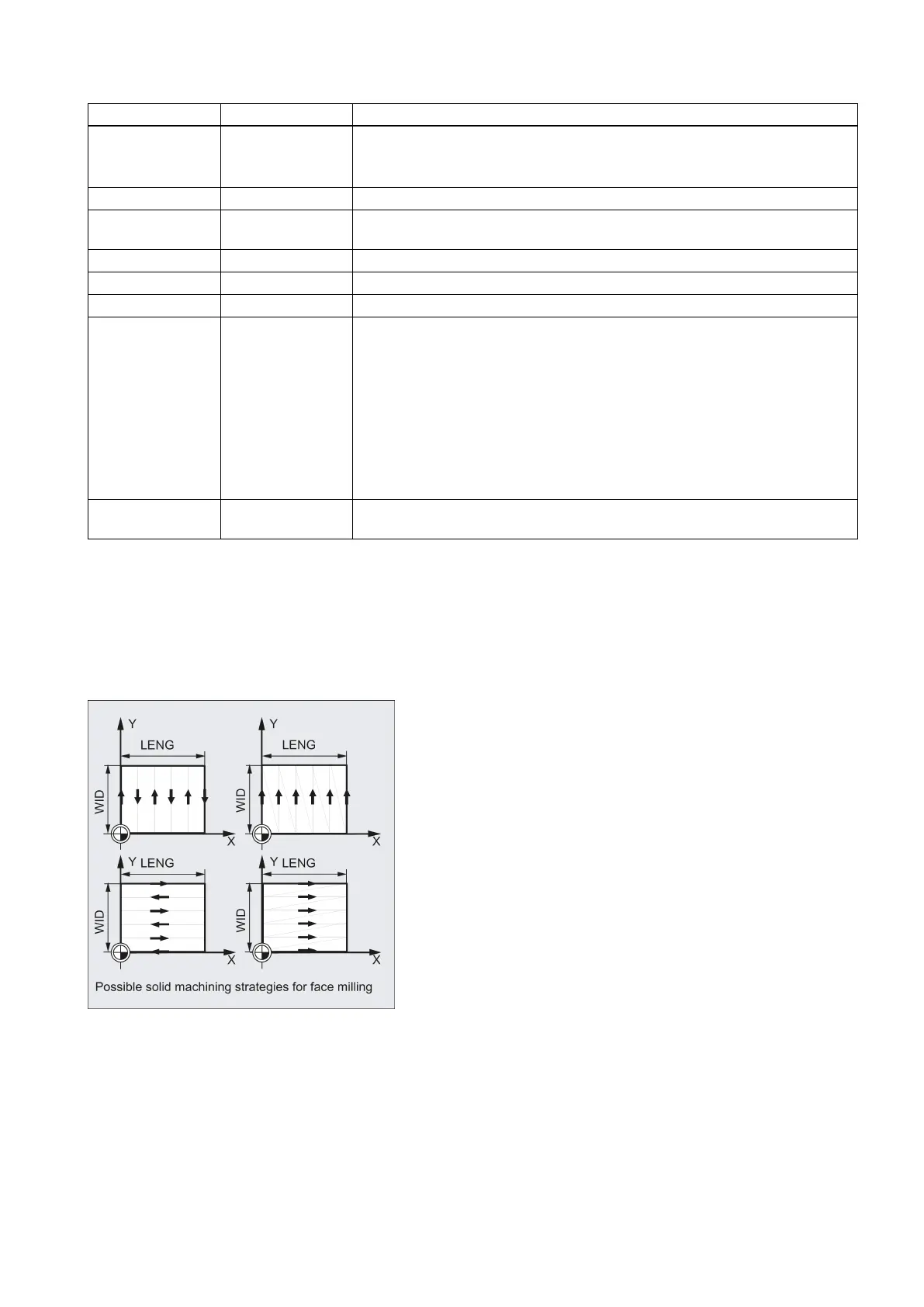

Use CYCLE71 to mill any rectangular surface. The cycle differentiates between roughing (machining the surface in several

steps until reaching the final machining allowance) and finishing (milling the end face in one step). The maximum infeed in

width and depth can be specified.

The cycle operates without cutter radius compensation. The depth infeed is performed in the open.

See the following illustration for possible face milling strategies:

Sequence

Position reached prior to cycle start:

Starting position is any position from which the infeed point can be approached at the height of the retraction plane without

collision.

Loading...

Loading...