Programming and Operating Manual (Milling)

82 6FC5398-4DP10-0BA1, 01/2014

Right-hand or left-hand thread

The

thread lead determines the direction of spindle rotation:

Positive: right-hand (as with M3)

Negative: left-hand (as with M4)

A complete thread tapping cycle with thread interpolation is provided with the standard cycle CYCLE84.

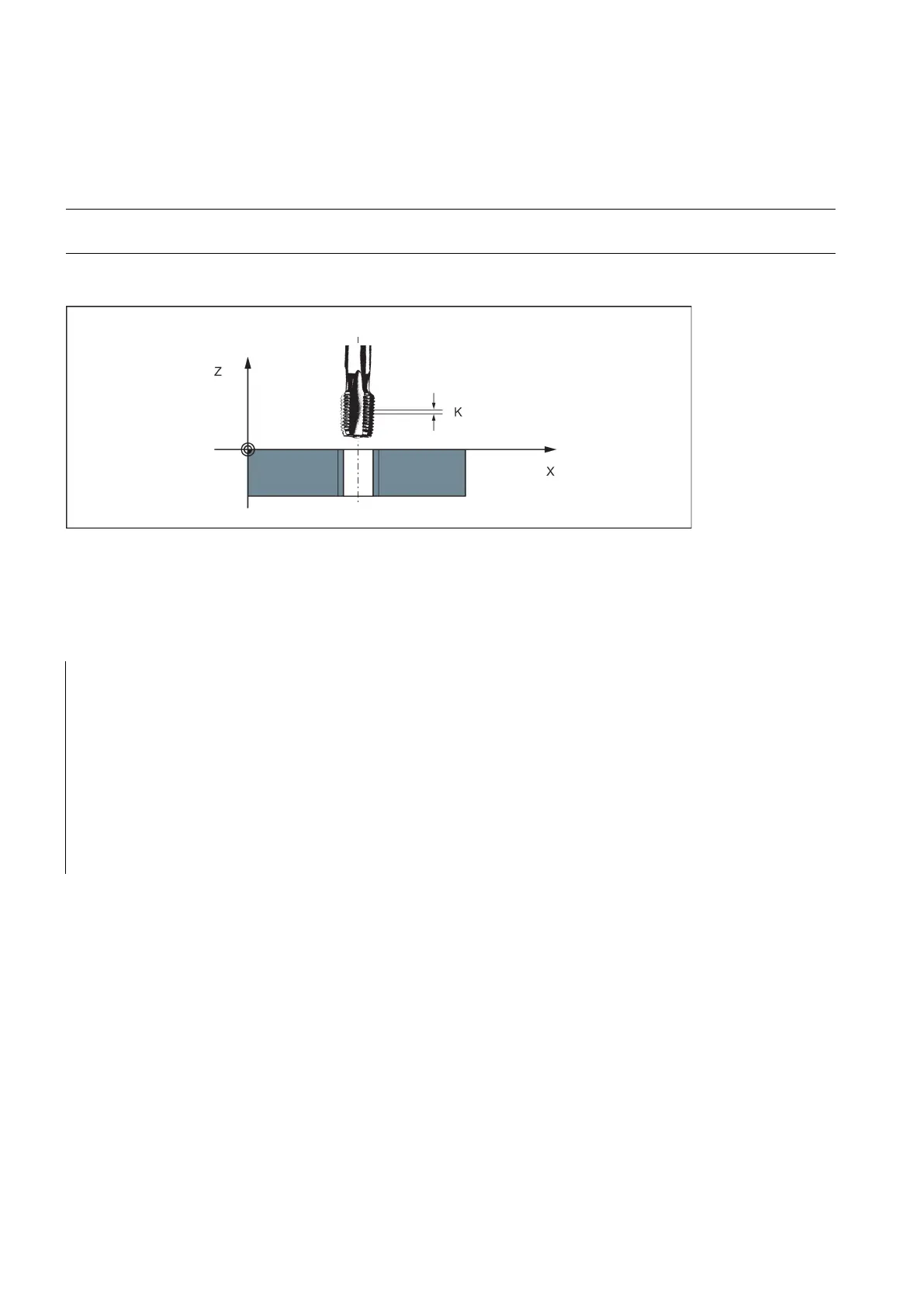

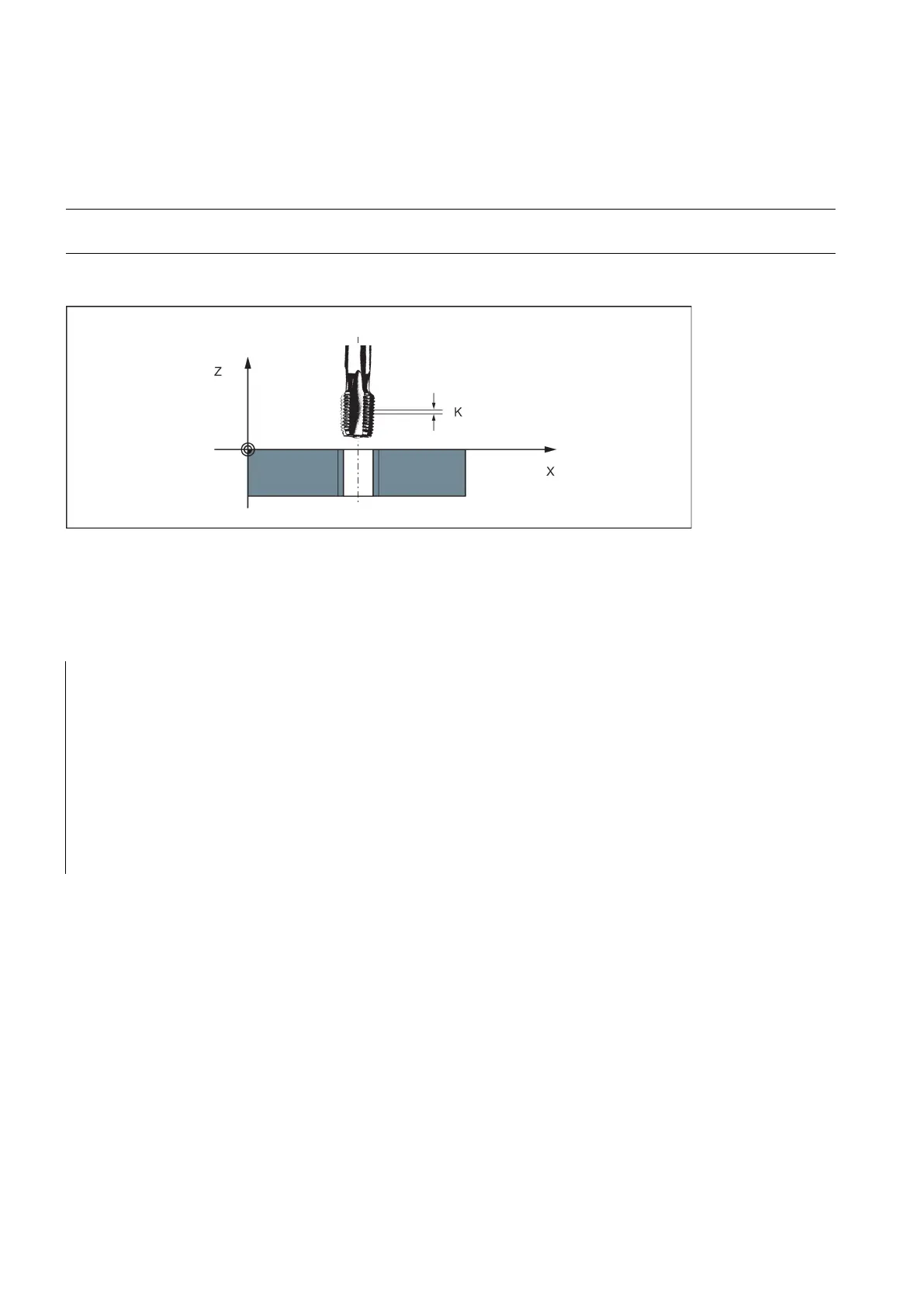

See the following illustration for tapping using G331/G332:

For G331/G332, the velocity of the axis for the thread length results from the spindle speed and the thread lead. The

feedrate F is not relevant

. It is, however, stored. However, the maximum axis velocity (rapid traverse) defined in the machine

data can not be exceeded. This will result in an alarm.

lead as per table: 0.8 mm/rev., hole already

; Approach starting point

; Spindle in position control

; Tapping, K positive = clockwise

of the spindle, end point Z=-25 mm

Fixed point approach

8.6.1

Fixed point approach: G75

Functionality

By using G75, a fixed point on the machine, e.g. tool change point, can be approached. The position is stored permanently

in the machine data for all axes. A maximum of four fixed points can be defined for each axis.

No offset is effective. The speed of each axis is its rapid traverse.

G75 requires a separate block and is non-modal. The machine axis identifier must be programmed!

In the block after G75, the previous G command of the "Interpolation type" group (G0, G1,G2, ...) is active again.

Loading...

Loading...