Programming and Operating Manual (Milling)

80 6FC5398-4DP10-0BA1, 01/2014

The drilling depth is specified by specifying one of the axes X, Y or Z; the thread pitch is specified via the relevant I, J or K.

G33 remains active until canceled by another instruction from this G group (G0, G1, G2, G3...).

Right-hand or left-hand thread

Right-hand or left-hand thread is set with the rotation direction of the spindle (M3 right (CW), M4 left (CCW) - see Section

"Spindle movements (Page 87)"). To do this, the rotation value must be programmed under address S or a rotation speed

must be set.

A complete cycle of tapping with compensating chuck is provided by the standard cycle CYCLE840.

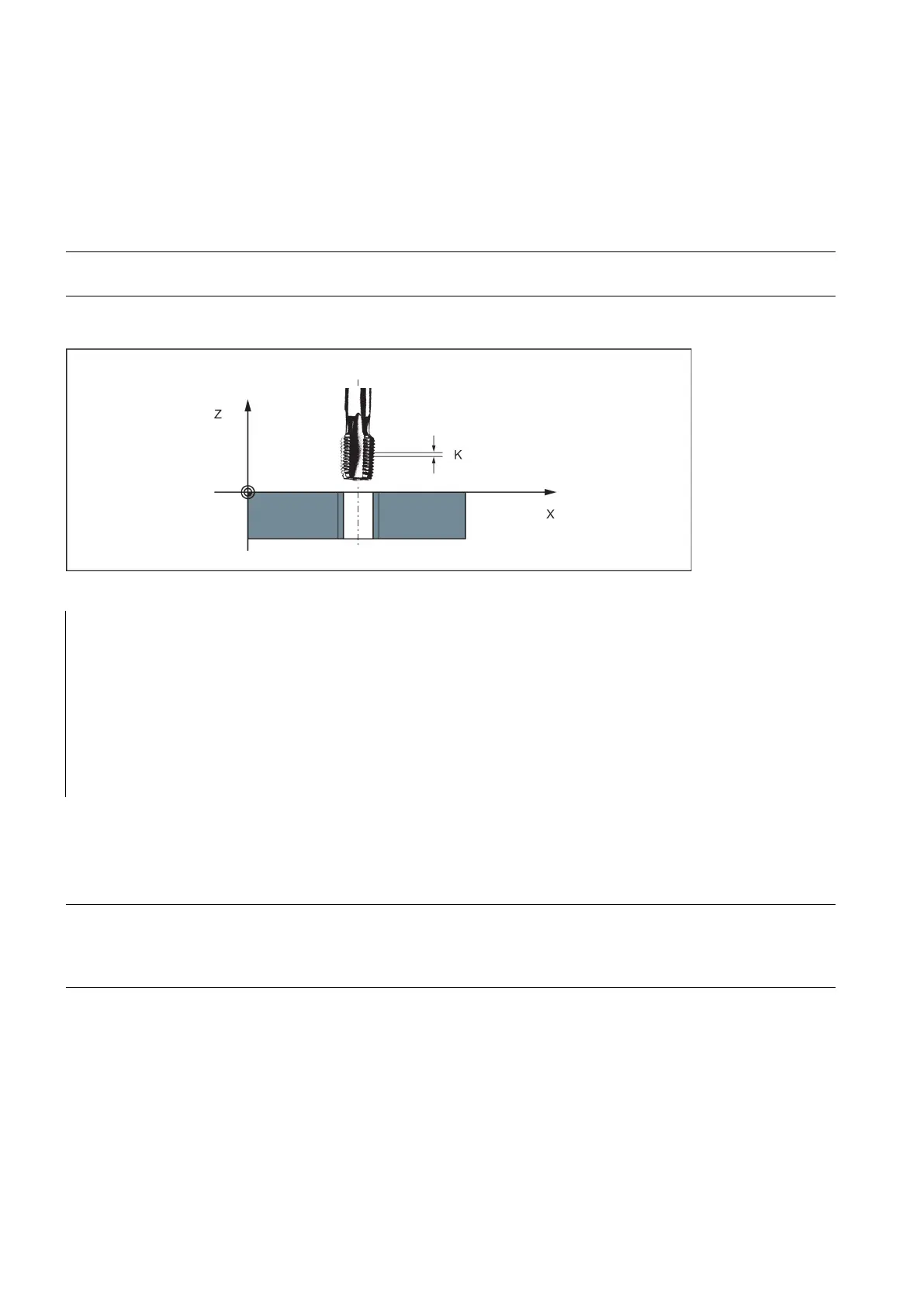

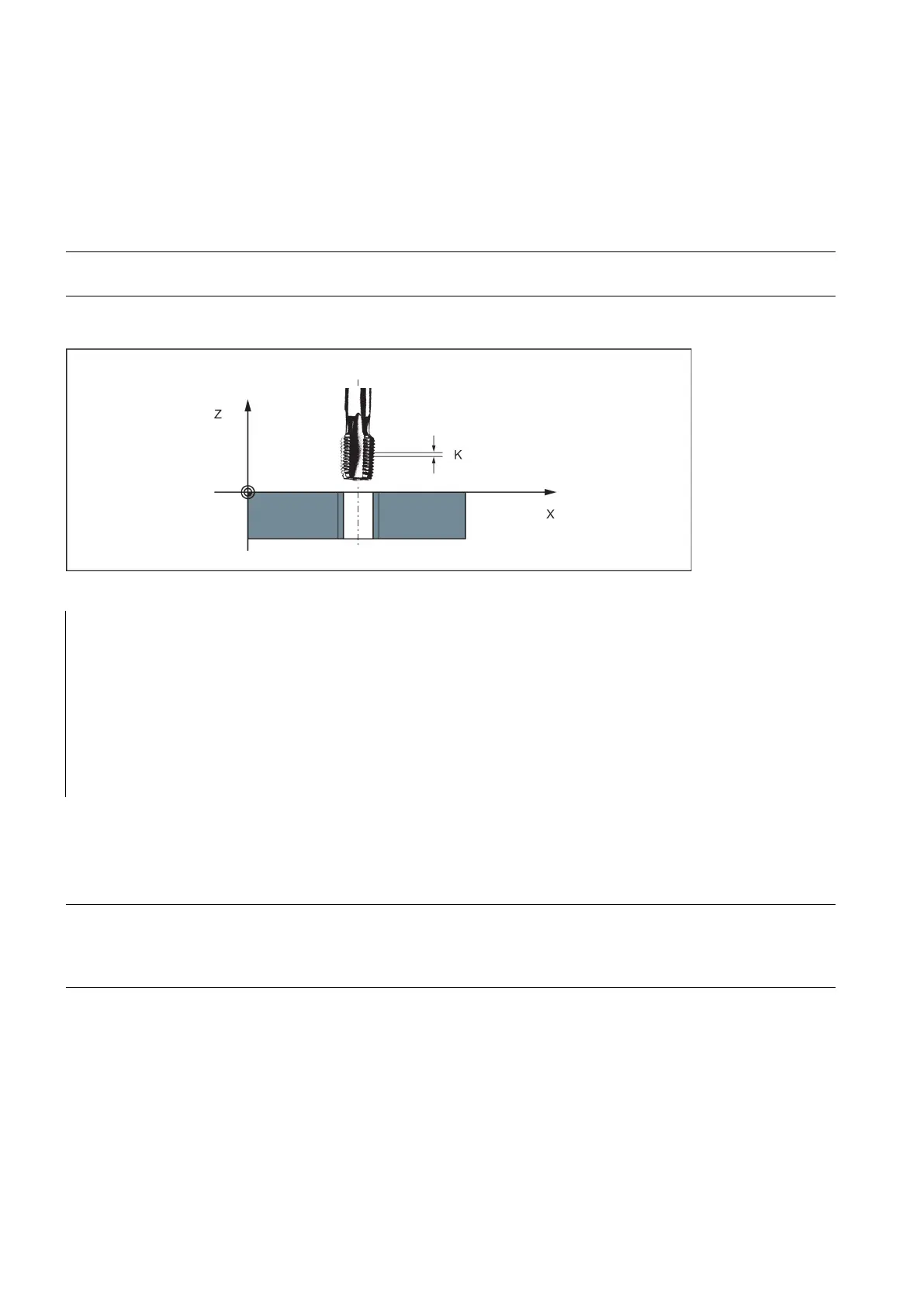

See the following illustration for tapping using G33:

; pitch as per table: 0.8 mm/rev., hole already

N10 G54 G0 G90 X10 Y10 Z5 S600 M3 ; Approach starting point, clockwise spindle

; Tapping, end point -25 mm

; Retraction, counter-clockwise spindle rotation

With G33 threads, the velocity of the axis for the thread lengths is determined on the basis of the spindle speed and the

thread pitch. The

feedrate F is not relevant

. It is, however, stored. However, the maximum axis velocity (rapid traverse)

defined in the machine data can not be exceeded. This will result in an alarm.

● The spindle speed override switch should remain unchanged for thread machining.

● The feedrate override switch has no meaning in this block.

Tapping with compensating chuck: G63

Functionality

G63 can be used for tapping with compensating chuck. The programmed feedrate F must match with the spindle speed S

(programmed under the address "S" or specified speed) and with the thread pitch of the drill:

F [mm/min] = S [rpm] x thread pitch [mm/rev.]

Loading...

Loading...