Programming and Operating Manual (Milling)

94 6FC5398-4DP10-0BA1, 01/2014

The tool selection takes place when the T word is programmed. Whether this is a

or only a

, is

defined in the machine data:

● The tool change (tool call) is performed either directly using the T word or

● The change takes place after the preselection with the T word by an additional instruction

(see also Section

"Miscellaneous function M (Page 103)").

If a certain tool is activated, it remains stored as an active tool even beyond the end of the program and after turning

off/turning on the control system.

If you change a tool manually, input the change in the control system so that the control system knows the correct tool.

For example, you can start a block with the new T word in MDA mode.

T... ; Tool number: 1 ... 32 000, T0 - no tool

The control system can store a maximum of 64 tools.

; Tool change without M6:

; Perform tool change; thereafter, T14 is active

Tool compensation number D

Functionality

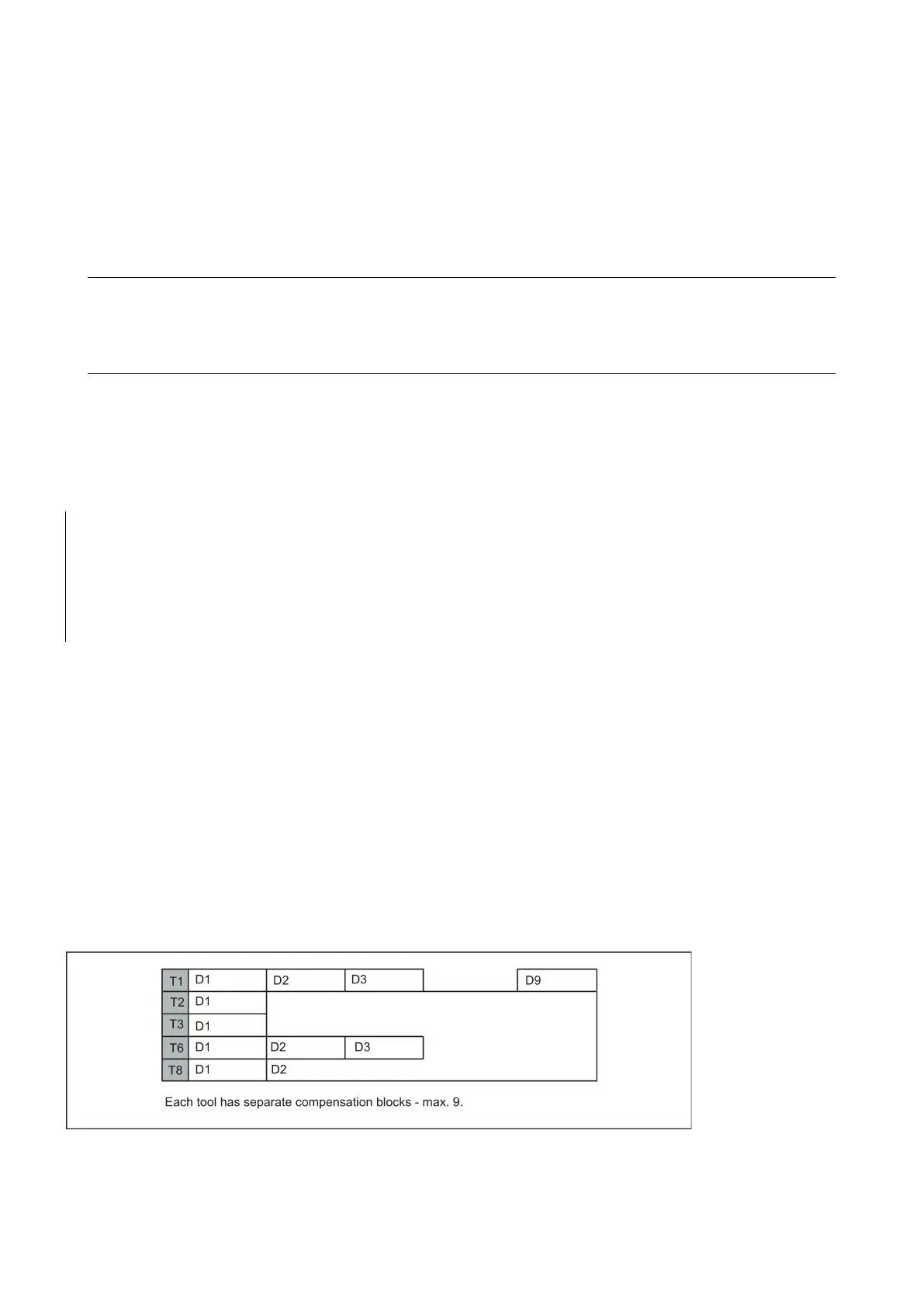

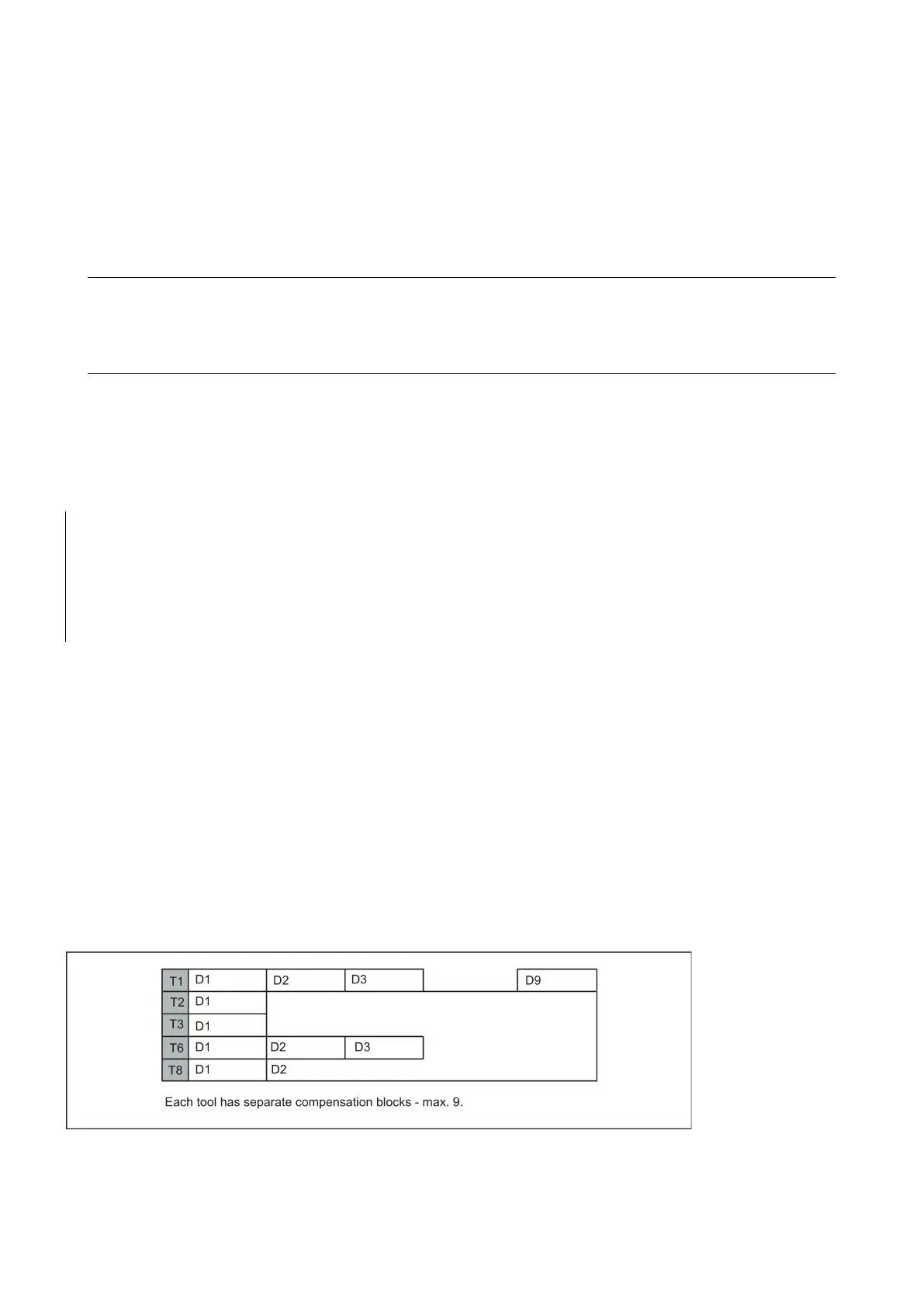

It is possible to assign 1 to 9 data fields with different tool offset blocks (for multiple cutting edges) to a specific tool. If a

special cutting tool is required, it can be programmed with D and the corresponding number.

If no D word is written, D1 takes effect

.

When

is programmed, offsets for the tool have no

.

D... ; Tool offset number: 1 ... 9,

D0: No compensations active!

A maximum of 64 data fields (D numbers) for tool offset blocks can be stored in the control system simultaneously:

See the following illustration for examples for assigning tool compensation numbers/tool:

Loading...

Loading...