Programming and Operating Manual (Milling)

206 6FC5398-4DP10-0BA1, 01/2014

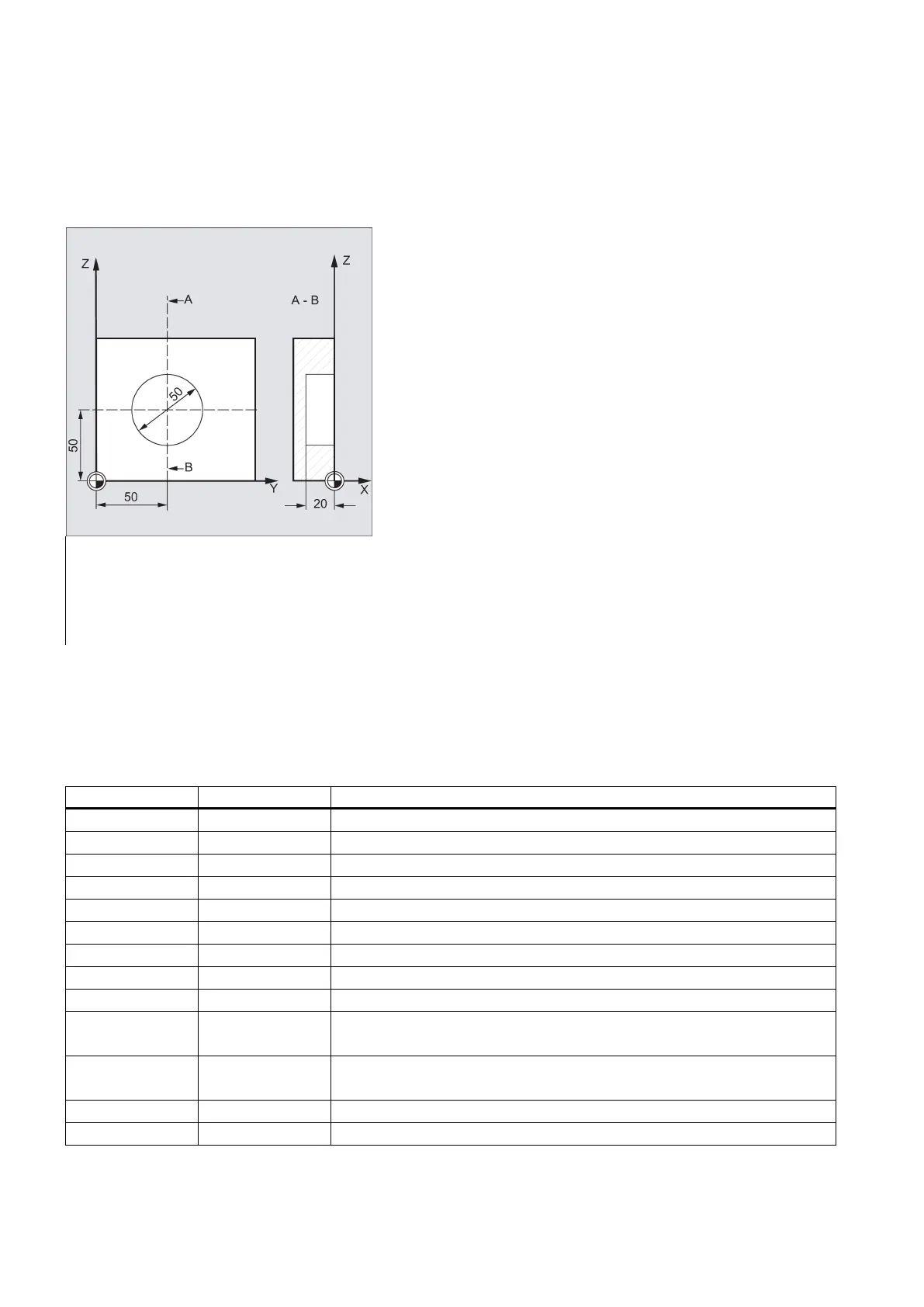

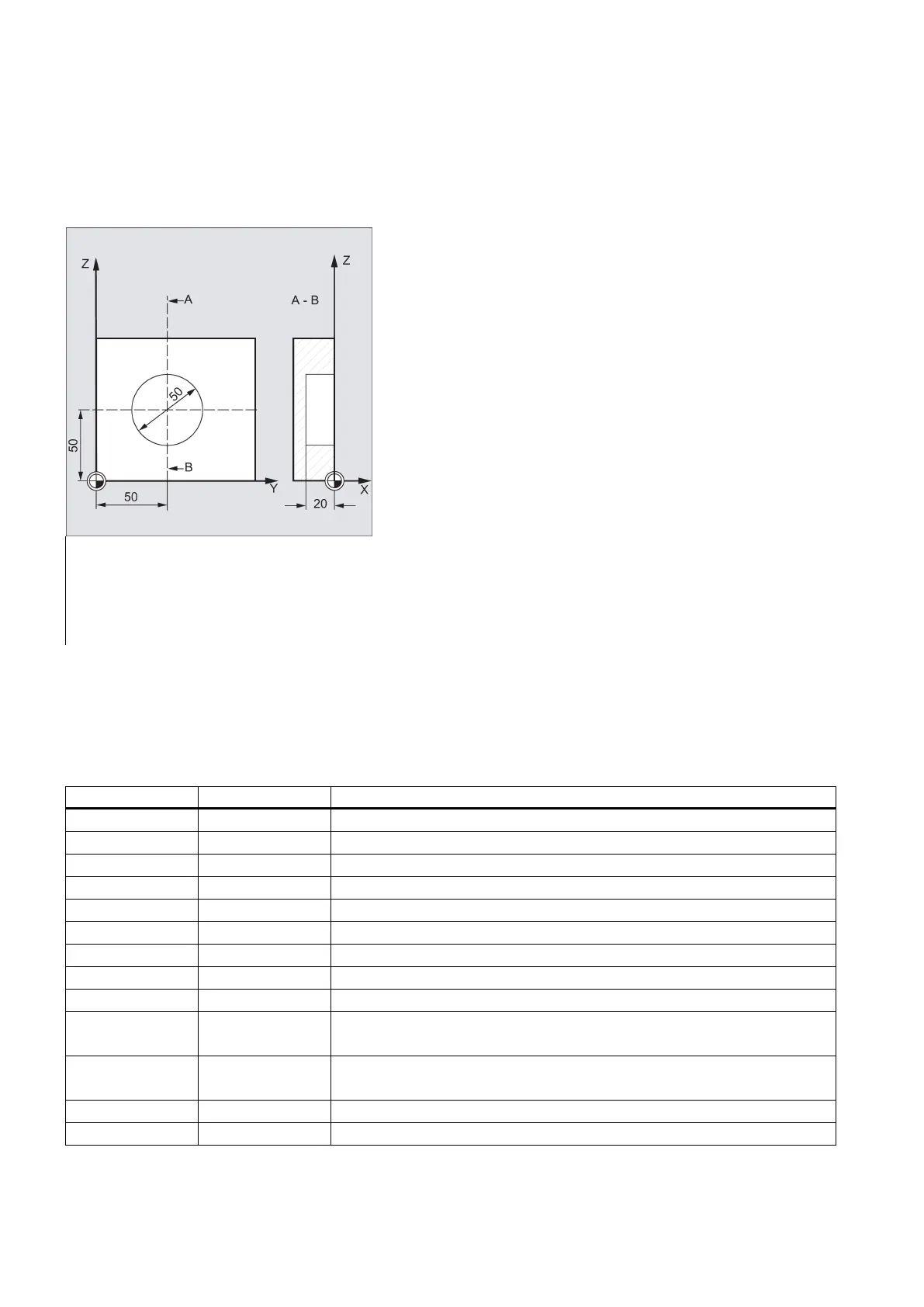

Programming example: Circular pocket

With this program, you can machine a circular pocket in the YZ plane. The center point is determined by Y50 Z50. The

infeed axis for the depth infeed is the X axis. Neither finishing dimension nor safety clearance is specified. The pocket is

machined with down-cut milling. Infeed is performed along a helical path.

A milling cutter with 10 mm radius is used. See the following programming example for circular pocket:

N10 G17 G90 G0 S650 M3 T1 D1

; Specification of technology values

; Approach starting position

N30 POCKET4(3, 0, 0, -20, 25, 50, 60, 6, 0, 0, 200, 100, 1,

21, 0, 0, 0, 2, 3)

; Cycle call

Parameters FAL and FALD are omitted

Thread milling - CYCLE90

Programming

CYCLE90 (RTP, RFP, SDIS, DP, DPR, DIATH, KDIAM, PIT, FFR, CDIR, TYPTH, CPA, CPO)

RTP REAL Retraction plane (absolute)

RFP REAL Reference plane (absolute)

SDIS REAL Safety clearance (enter without sign)

DP REAL Final drilling depth (absolute)

DPR REAL Final drilling depth relative to the reference plane (enter without sign)

DIATH REAL Nominal diameter, outer diameter of the thread

KDIAM REAL Core diameter, internal diameter of the thread

PST REAL Thread pitch; value range: 0.001 ... 2000.000 mm

FFR REAL Feedrate for thread milling (enter without sign)

CDIR INT Direction of rotation for thread milling

Values: 2 (for thread milling with G2), 3 (for thread milling with G3)

TYPTH INT Thread type

Values: 0=internal thread, 1=external thread

CPA REAL Center point of circle, abscissa (absolute)

CPO REAL Center point of circle, ordinate (absolute)

Loading...

Loading...