Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA1, 01/2014

193

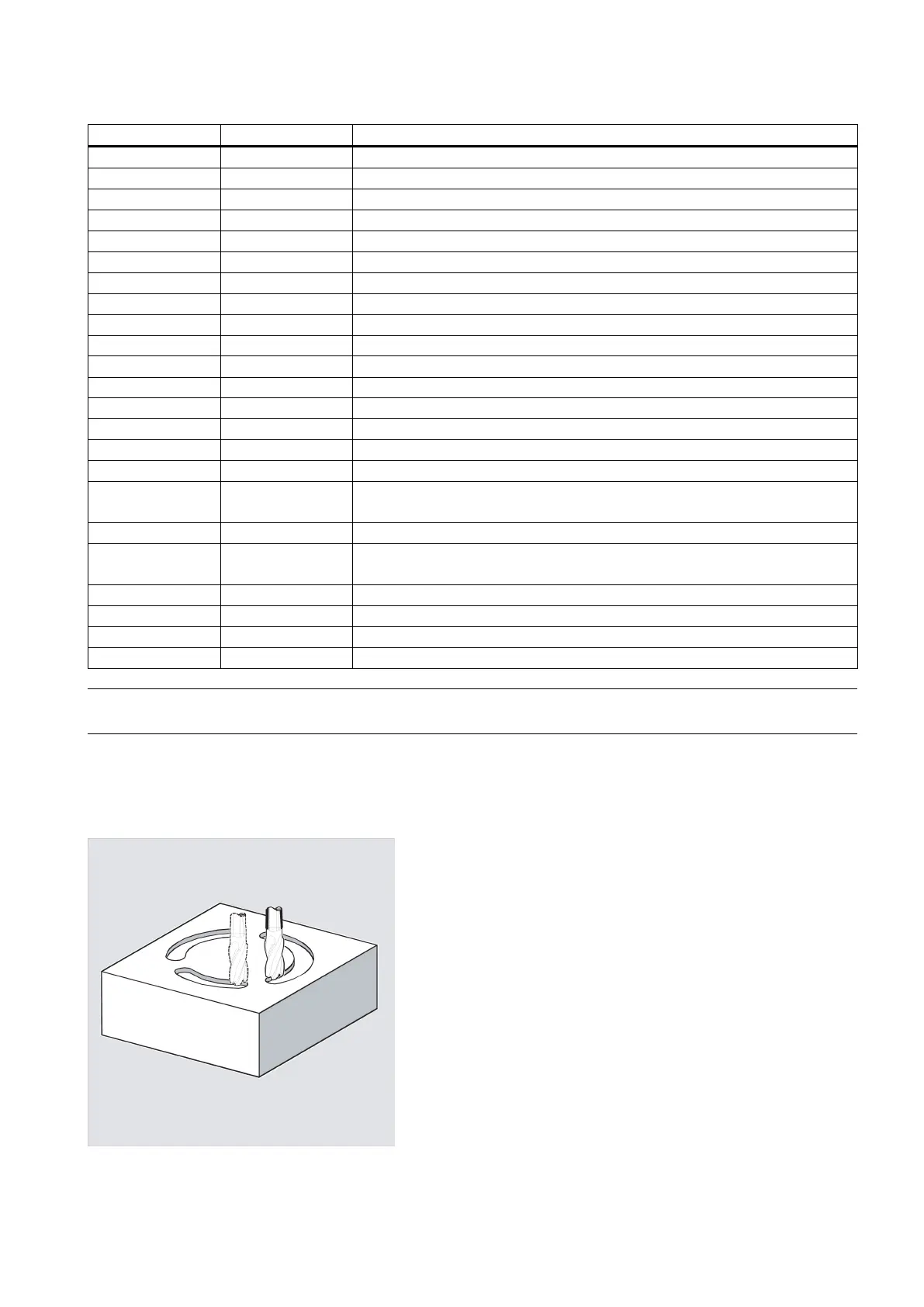

RTP REAL Retraction plane (absolute)

RFP REAL Reference plane (absolute)

SDIS REAL Safety clearance (enter without sign)

DP REAL Slot depth (absolute)

DPR REAL Slot depth relative to the reference plane (enter without sign)

NUM INT Number of slots

AFSL REAL Angle for the slot length (enter without sign)

WID REAL Circumferential slot width (enter without sign)

CPA REAL Center point of circle (absolute), first axis of the plane

CPO REAL Center point of circle (absolute), second axis of the plane

RAD REAL Radius of the circle (enter without sign)

STA1 REAL Starting angle

INDA REAL Incrementing angle

FFD REAL Feedrate for depth infeed

FFP1 REAL Feedrate for surface machining

MID REAL Maximum infeed depth for one infeed (enter without sign)

CDIR INT Milling direction for machining the circumferential slot

Values: 2 (for G2), 3 (for G3)

FAL REAL Finishing allowance at the slot edge (enter without sign)

VARI INT Machining type

Values: 0 = complete machining, 1 = roughing, 2 = finishing

MIDF REAL Maximum infeed depth for finishing

FFP2 REAL Feedrate for finishing

SSF REAL Speed when finishing

FFCP REAL Feedrate for intermediate positioning on a circular path, in mm/min

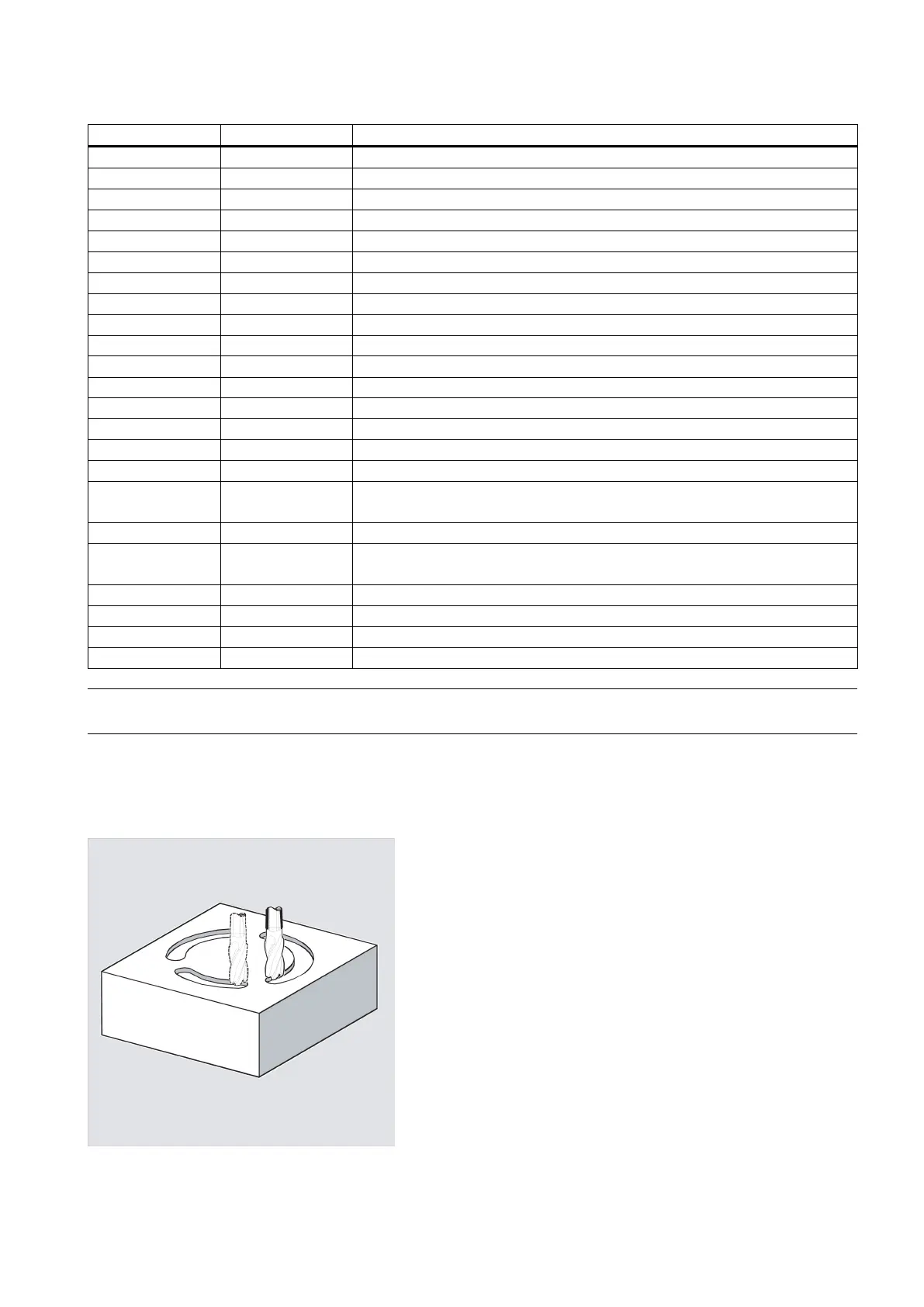

The cycle requires a milling cutter with an "end tooth cutting across center" (DIN844).

The cycle SLOT2 is a combined roughing-finishing cycle.

Use this cycle to machine circumferential slots arranged on a circle.

Loading...

Loading...