Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA1, 01/2014

131

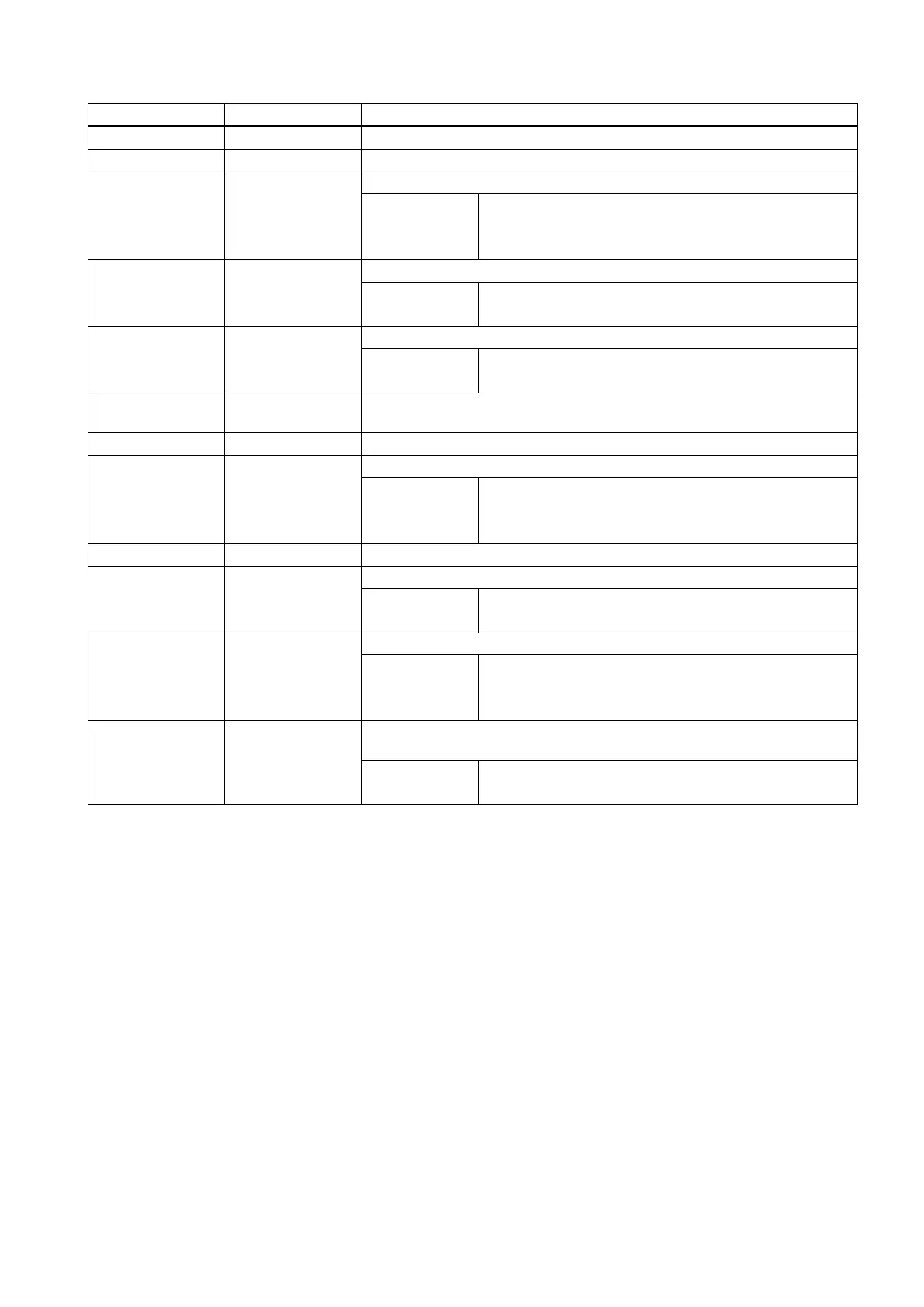

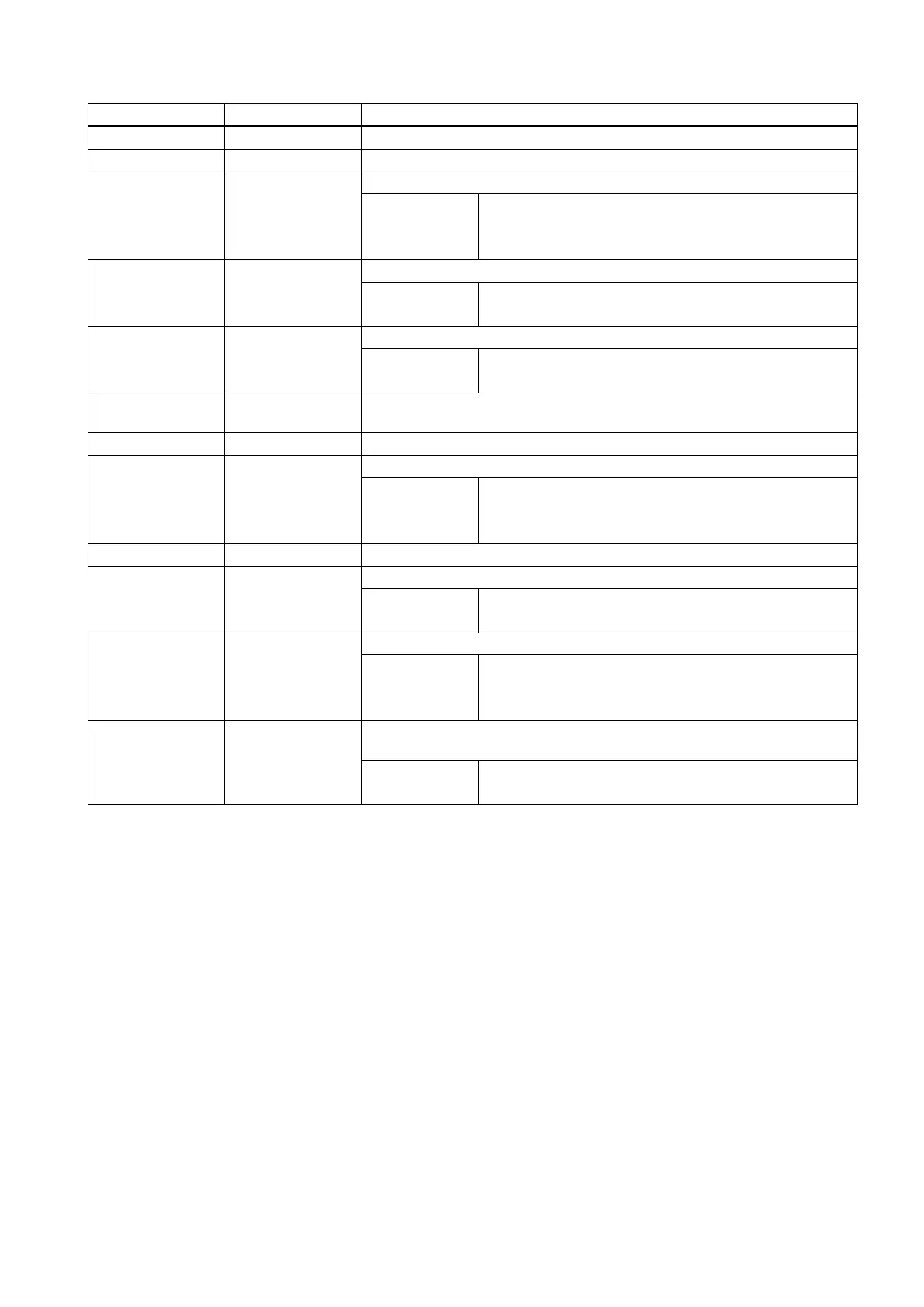

FDEP REAL First drilling depth (absolute)

FDPR REAL First drilling depth relative to the reference plane (enter without sign)

DAM REAL Amount of degression (enter without sign)

Values: >0: degression as value

<0: degression factor

=0: no degression

DTB REAL Dwell time at drilling depth (chip breakage)

Values: >0: in seconds

<0: in revolutions

DTS REAL Dwell time at starting point and for chip removal

Values: >0: in seconds

<0: in revolutions

FRF REAL Feedrate factor for the first drilling depth (enter without sign) Range of values:

0.001 ... 1

VARI INT Machining type: Chip breakage=0, Chip removal=1

AXN INT Tool axis

Values: 1: 1st geometrical axis

2: 2nd geometrical axis

3: 3rd geometrical axis

MDEP REAL Minimum drilling depth (only in connection with degression factor)

VRT REAL Variable retraction value for chip breakage (VARI=0)

Values: >0: if traction value

=0: retraction value 1mm set

DTD REAL Dwell time at final drilling depth

Values: >0: in seconds

<0: in revolutions

=0: value same as DTB

DIS1 REAL Programmable limit distance for reinsertion in the drill hole (for chip removal

VARI=1)

Values: >0: programmable value applies

=0: automatic calculation

The tool drills at the programmed spindle speed and feedrate to the entered final drilling depth.

Deep hole drilling is performed with a depth infeed of a maximum definable depth executed several times, increasing

gradually until the final drilling depth is reached.

The drill can either be retracted to the reference plane + safety clearance after every infeed depth for swarf removal or

retracted in each case by 1 mm for chip breaking.

Sequence

Position reached prior to cycle start:

The drilling position is the position in the two axes of the selected plane.

The cycle creates the following sequence:

Deep hole drilling with chip removal (VARI=1)

● Approach of the reference plane brought forward by the safety clearance by using G0

Loading...

Loading...