Programming and Operating Manual (Milling)

134 6FC5398-4DP10-0BA1, 01/2014

DTD (dwell time at final drilling depth)

The dwell time at final drilling depth can be entered in seconds or revolutions.

DIS1 (programmable limit distance for VARI=1)

The limit distance after re-insertion in the hole can be programmed.

The limit distance is calculated within the cycle as follows:

● Up to a drilling depth of 30 mm, the value is set to 0.6 mm.

● For larger drilling depths, the limit distance is the result of

(RFP + SDIS – current depth) / 50. If this calculated value >7, a limit of 7 mm, maximum, is applied.

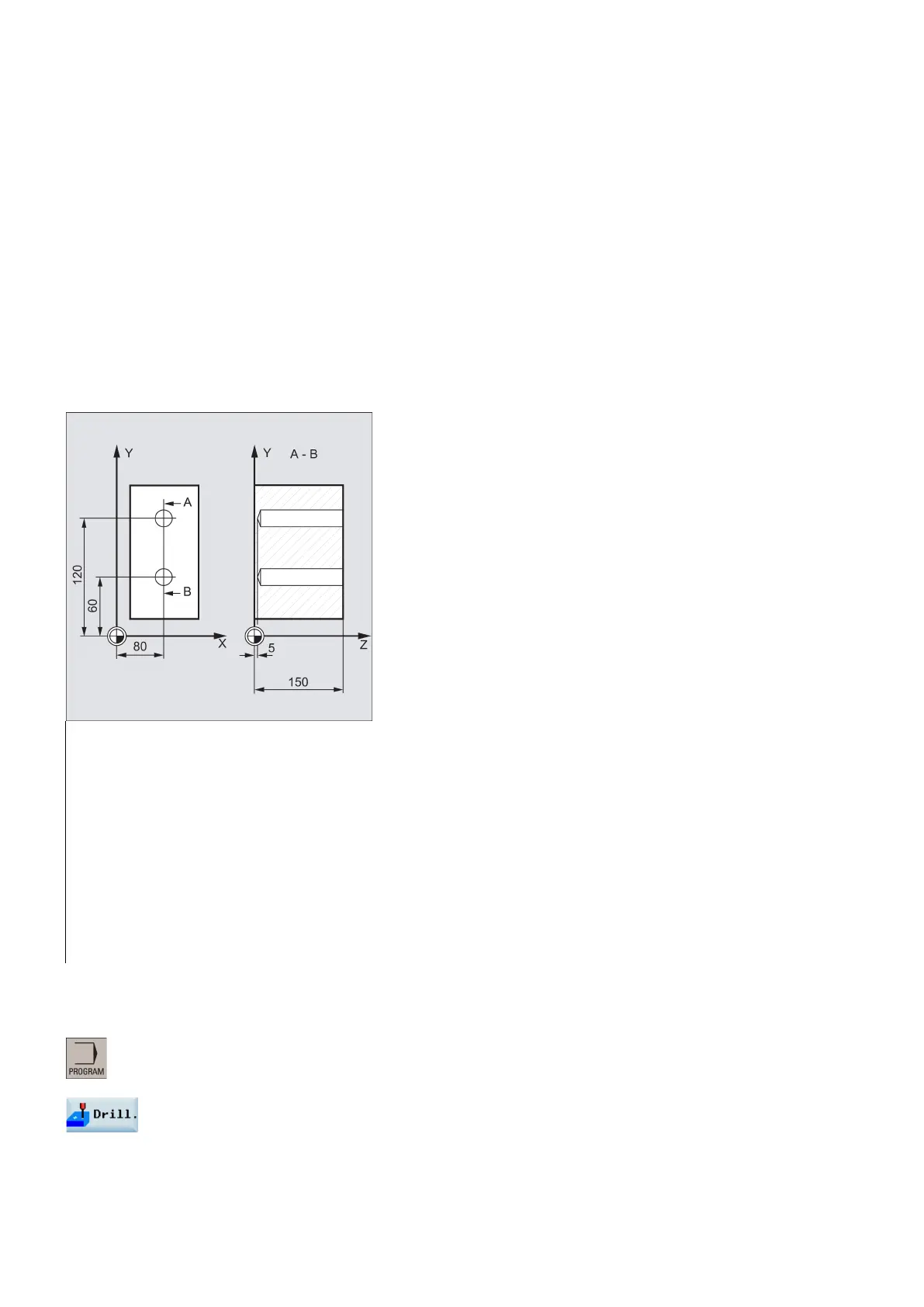

Programming example1: Deep-hole drilling

This program executes the cycle CYCLE83 at the positions X80 Y120 and X80 Y60 in the XY plane. The first drill hole is

drilled with a dwell time zero and machining type chip breaking. The final drilling depth and the first drilling depth are entered

as absolute values. In the second cycle call, a dwell time of 1 s is programmed. Machining type chip removal is selected, the

final drilling depth is relative to the reference plane. The drilling axis in both cases is the Z axis.

N10 G0 G17 G90 F50 S500 M4

; Specification of technology values

; Approach retraction plane

; Approach first drilling position

N50 CYCLE83(20,0,3,-15,,-6,,1,1,1,1,0,3,4,3,1,2) ; Call of cycle; depth parameters with

; Approach next drilling position

N70 CYCLE83(20,0,3,-15,,-6,,1,1,1,1,0,3,4,3,1,2) ; Cycle call with relative data for final

drilling depth and first drilling depth;

the safety clearance is 1 mm and the

Programming example 2: Deep-hole drilling

Proceed through the following steps:

1. Select the desired operating area.

2. Open the vertical softkey bar for available drilling cycles.

Loading...

Loading...