Programming and Operating Manual (Milling)

188 6FC5398-4DP10-0BA1, 01/2014

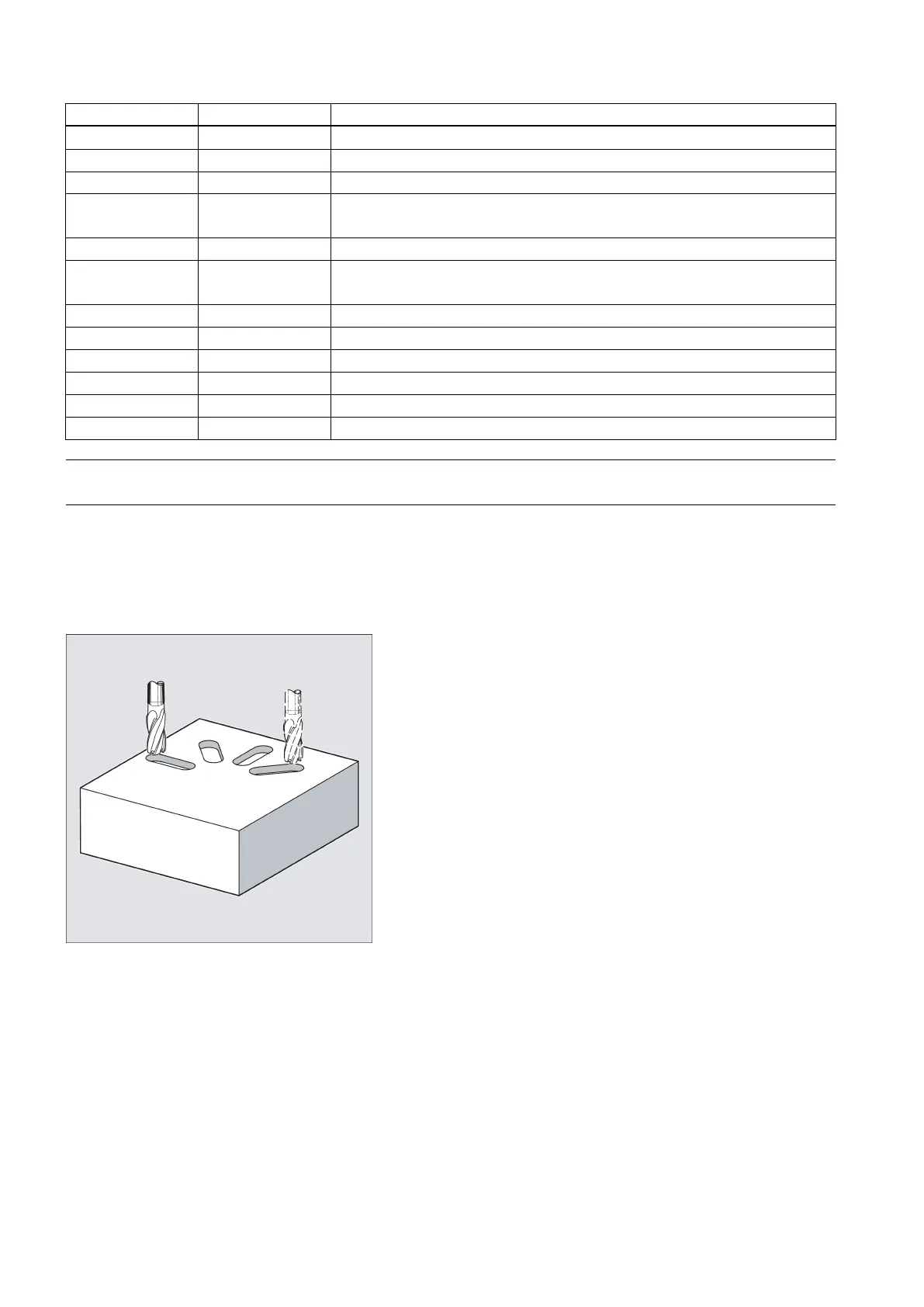

FFD REAL Feedrate for depth infeed

FFP1 REAL Feedrate for surface machining

MID REAL Maximum infeed depth for one infeed (enter without sign)

CDIR INT Milling direction for machining the slot

Values: 2 (for G2), 3 (for G3)

FAL REAL Finishing allowance at the slot edge (enter without sign)

VARI INT Machining type

Values: 0 = complete machining, 1 = roughing, 2 = finishing

MIDF REAL Maximum infeed depth for finishing

FFP2 REAL Feedrate for finishing

SSF REAL Speed when finishing

FALD REAL Finishing allowance at the slot base (enter without sign)

STA2 REAL Maximum insertion angle for oscillation movement

DP1 REAL Insertion depth per revolution for helix (incremental)

The cycle requires a milling cutter with an "end tooth cutting across center" (DIN844).

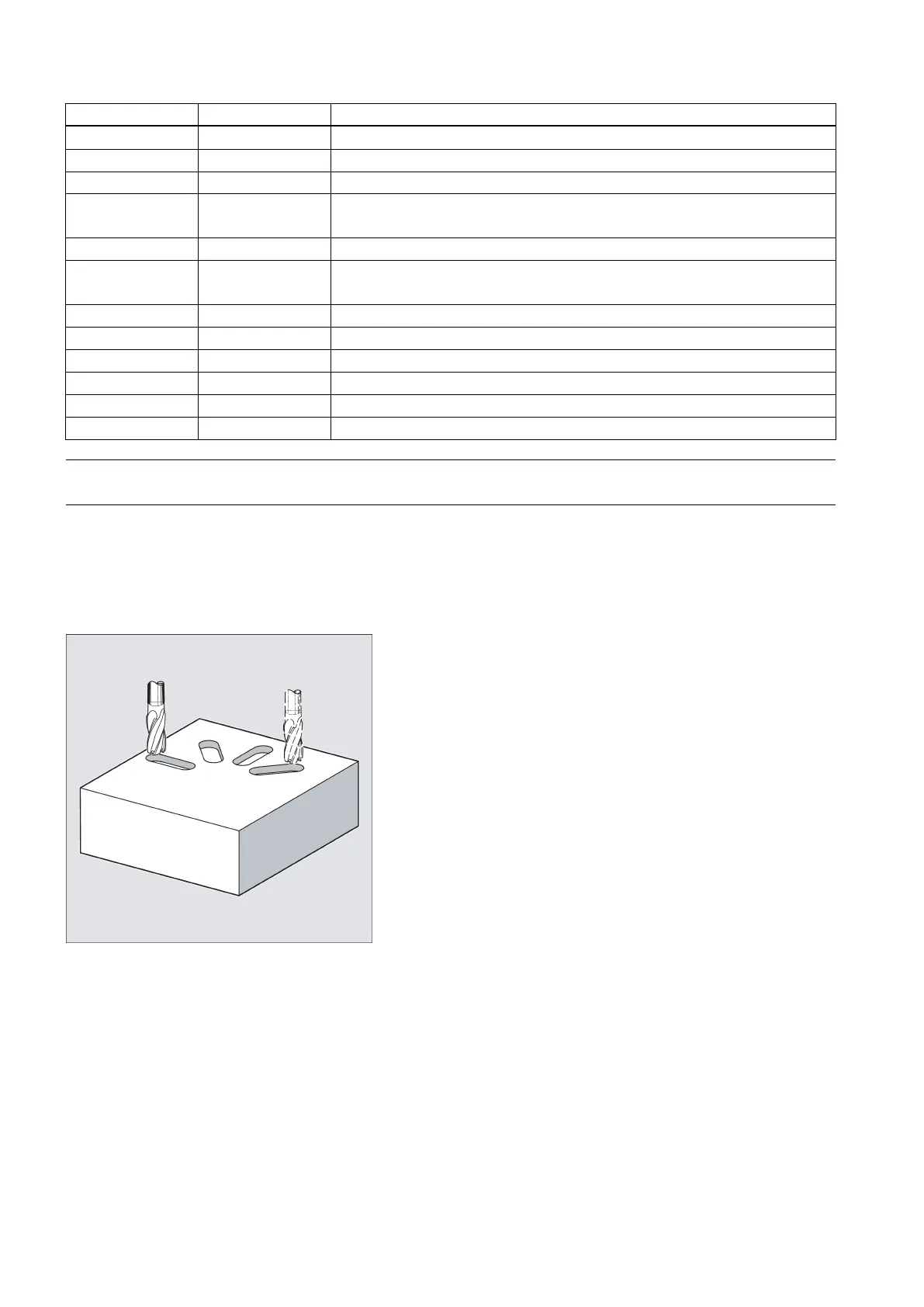

The cycle SLOT1 is a combined roughing-finishing cycle.

Use this cycle to machine slots arranged on a circle. The longitudinal axis of the slots is aligned radially. In contrast to the

long hole, a value is defined for the slot width.

Sequence

Position reached prior to cycle start:

The starting position can be any position from which each of the slots can be approached without collision.

Loading...

Loading...