Programming and Operating Manual (Milling)

66 6FC5398-4DP10-0BA1, 01/2014

Activate cylinder surface transformation:

Required tool: T1 milling tool, radius=3 mm, edge position=8

N10 T1 D1 G54 G90 G94

; Tool selection, clamping compensation

; Approach the starting position

; Set the second spindle as the main spindle

; Change the diameter dimensioning to radius dimensioning

; Activate cylinder surface ;transformation

Machining a hook-shaped groove:

; Approach starting position

; Tool radius compensation right of contour on

; Tool radius compensation off

; Retraction in rapid traverse

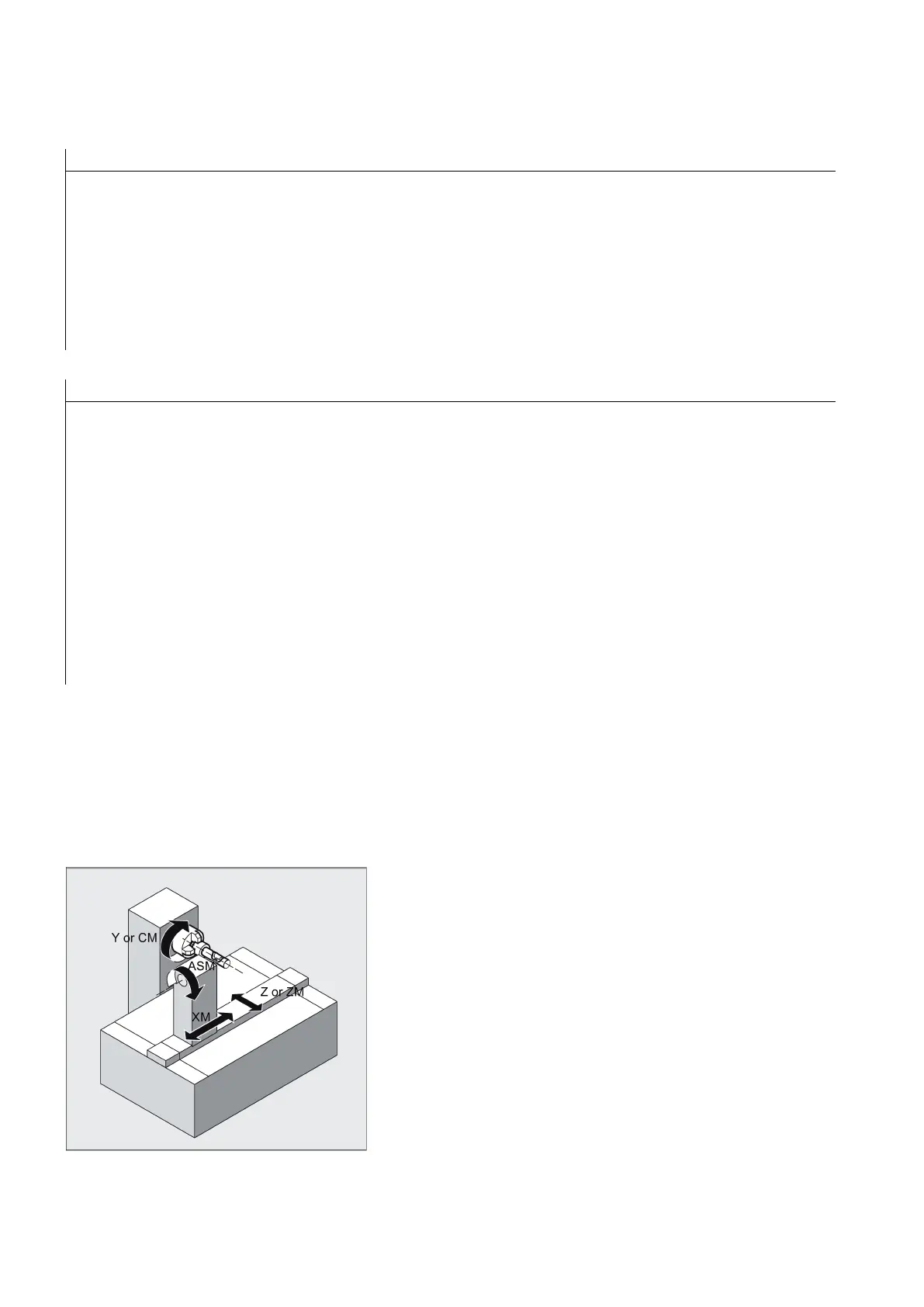

Description

Without groove wall offset (transformation type 512)

The controller transforms the programmed traversing movements of the cylinder coordinate system to the traversing

movements of the real machine axes:

● Rotary axis

● Infeed axis perpendicular to rotary axis

● Longitudinal axis parallel to rotary axis

The linear axes are positioned perpendicular to one another. The infeed axis cuts the rotary axis.

Loading...

Loading...