[7sj6x-stromsummenueberw-20070315, 1, en_US]

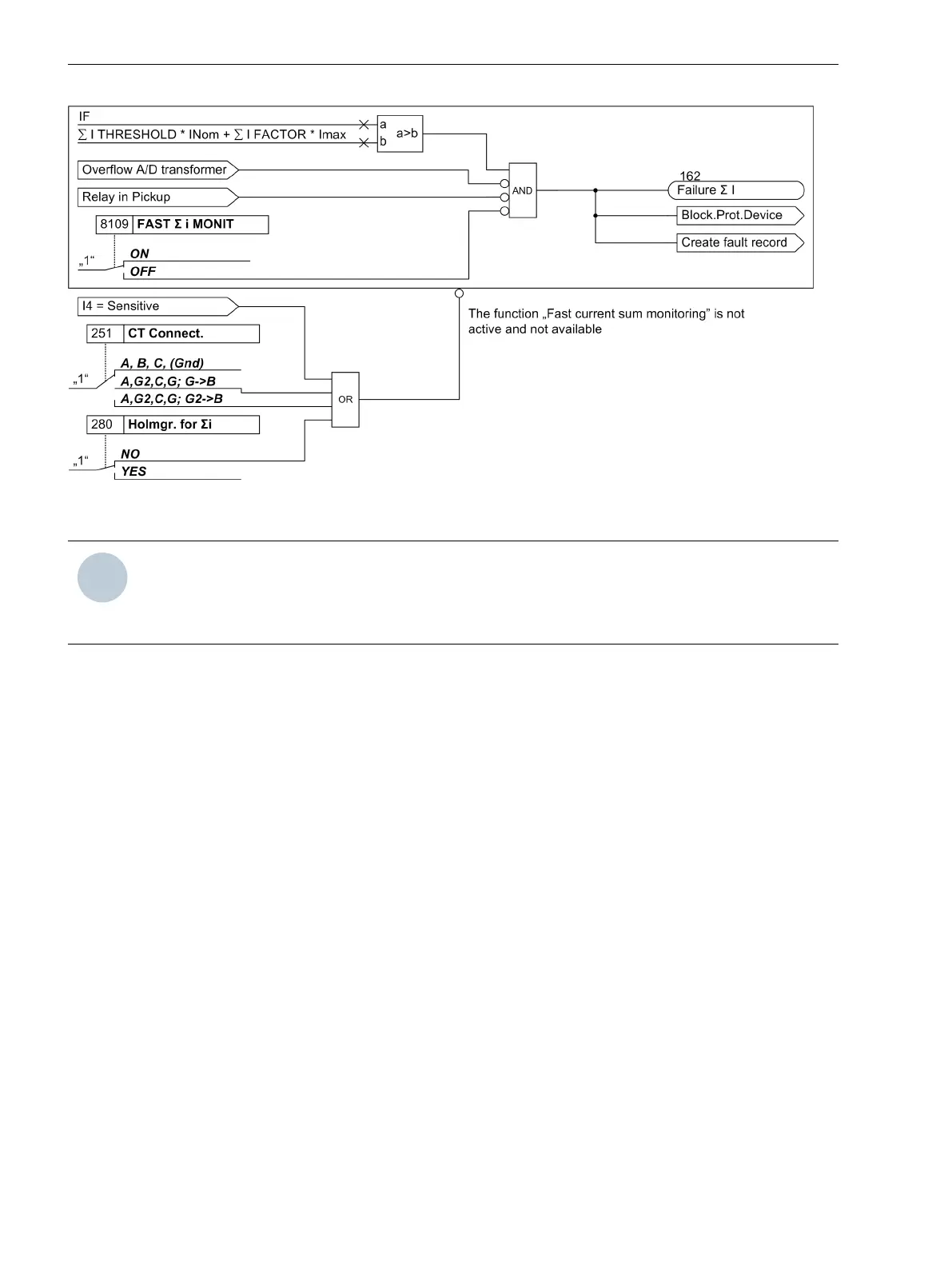

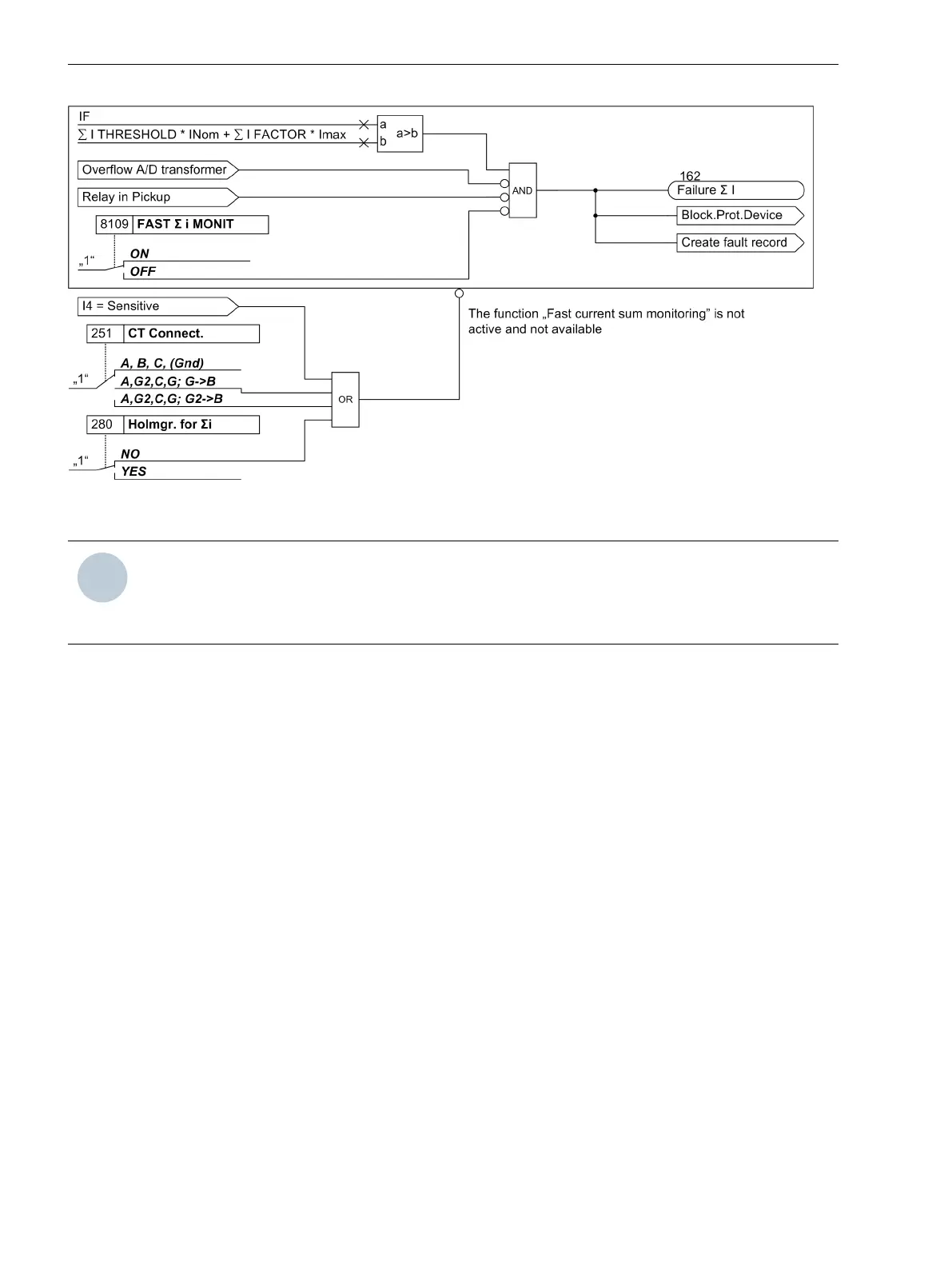

Figure 2-56 Logic Diagram of the fast current sum monitoring

NOTE

If the current input IN is configured as a sensitive transformer or if the connection mode A,G2,C,G; G-

>B or A,G2,C,G; G2->B was set for the current transformers at parameter 251 CT Connect., current

sum monitoring is not possible.

AD Transformer Monitoring

The digitized sampled values are being monitored in respect of their plausibility. If the result is not plausible,

message 181

Error A/D-conv.

is issued. The protection is blocked, thus preventing unwanted operation.

Furthermore, a fault record is generated for recording of the internal fault.

Software Monitoring

Watchdog

For continuous monitoring of the program sequences, a time monitor is provided in the hardware (hardware

watchdog) that expires upon failure of the processor or an internal program, and causes a complete restart of

the processor system.

An additional software watchdog ensures that malfunctions during the processing of programs are discov-

ered. This also initiates a restart of the processor system.

If such a malfunction is not cleared by the restart, an additional restart attempt is begun. After three unsuc-

cessful restarts within a 30 second window of time, the device automatically removes itself from service and

the red “Error” LED lights up. The readiness relay drops out and indicates „device malfunction“ with its normally

closed contact.

Offset Monitoring

This monitoring function checks all ring buffer data channels for corrupt offset replication of the analog/digital

transformers and the analog input paths using offset filters. Possible offset errors are detected using DC filters,

and the associated sampled values are corrected up to a specific limit. If this limit is exceeded, an indication is

generated (191

Error Offset

) and integrated into the warning group indication (160). As increased offset

values impair the measurements, we recommend sending the device to the OEM plant for corrective action

should this indication persist.

2.11.1.3

Functions

2.11 Monitoring Functions

156 SIPROTEC 4, 7SJ80, Manual

E50417-G1140-C343-A8, Edition 12.2017

Loading...

Loading...