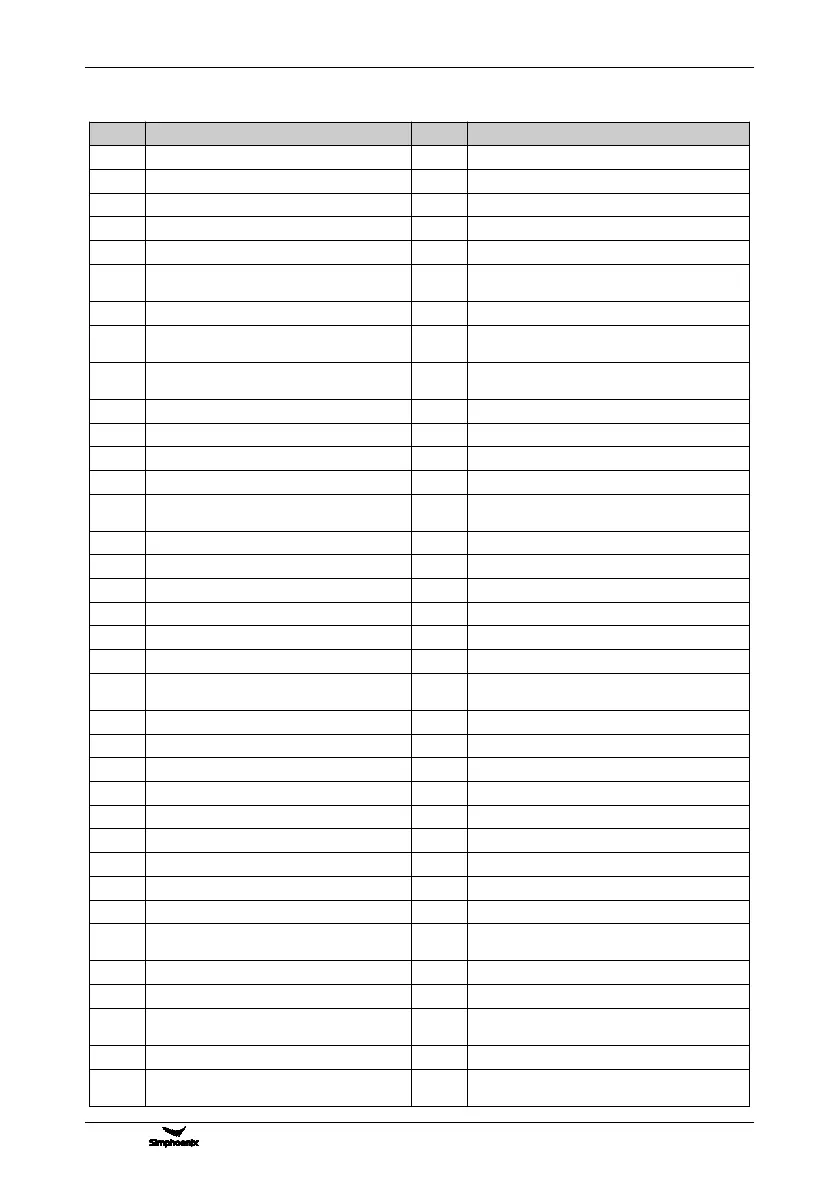

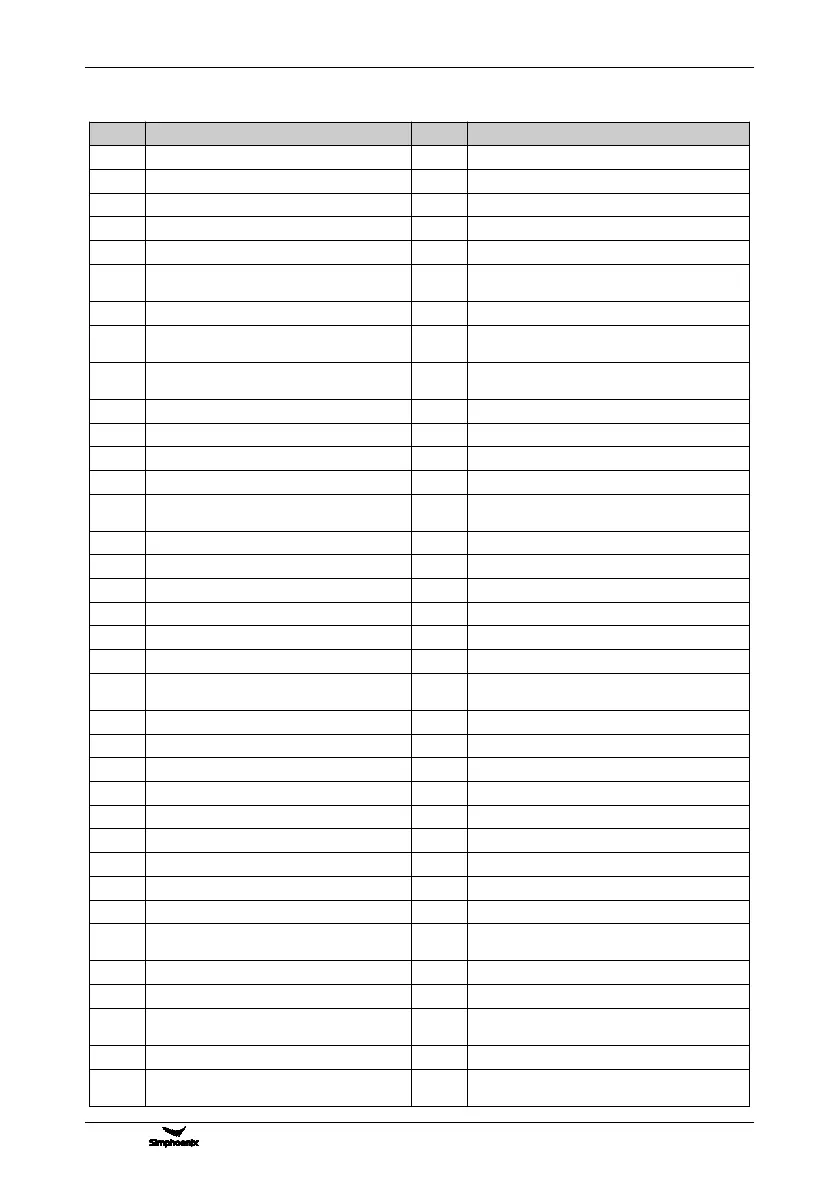

Functional Parameter Table

V800 Series High Performance Closed-Loop Vector Inverter User Manual

Table 1: Comparison Table of Multifunctional Input Terminal (DI/EDI/SDI) Functions

Forward (FWD) running command terminal

Reverse (REV)running command terminal

Acceleration and deceleration time selection 1

Acceleration and deceleration time selection

2

Running command switching

Frequency command switching

Fault resetting input (RESET)

Frequency or Process PID set value ascending

(UP)

Frequency or Process PID set value

descending (DW)

UP/DW set frequency clear

Three-line running control

Acceleration and deceleration forbidden

Simple PLC multi-stage running effective

Swing frequency running effective

Compensation PID effective

Simple PLC multi-stage running status

(when stopping ) resetting

Swing frequency status resetting (effective

when stopping)

Multi-stage process PID giving terminal 1

Multi-stage Process PID giving terminal 2

Multi-stage process PID giving terminal 3

Process PID setting selection (switching)

Process PID feedback selection (switching)

Process PID sleep activation

Torque/speed control mode switching

Minimum torque limiting set value selection

Maximum torque limiting set value selection

overvoltage suppression input

Load dynamic balancing effective

RS485 external/Standard operation panel

control switching

Counter 1 resetting terminal

Counter 2 resetting terminal

Single pulse accumulative length value

resetting

Motor temperature detection contact input

Compensation PID parameter selection1

Compensation PID parameter selection 2

Position pulse counting (PG pulse counting

accumulation) resetting

Automatic shifting (Spindle shifting jog running)

Servo pulse command direction (Fin)

Spindle positioning origin photoelectric

signal input

Loading...

Loading...