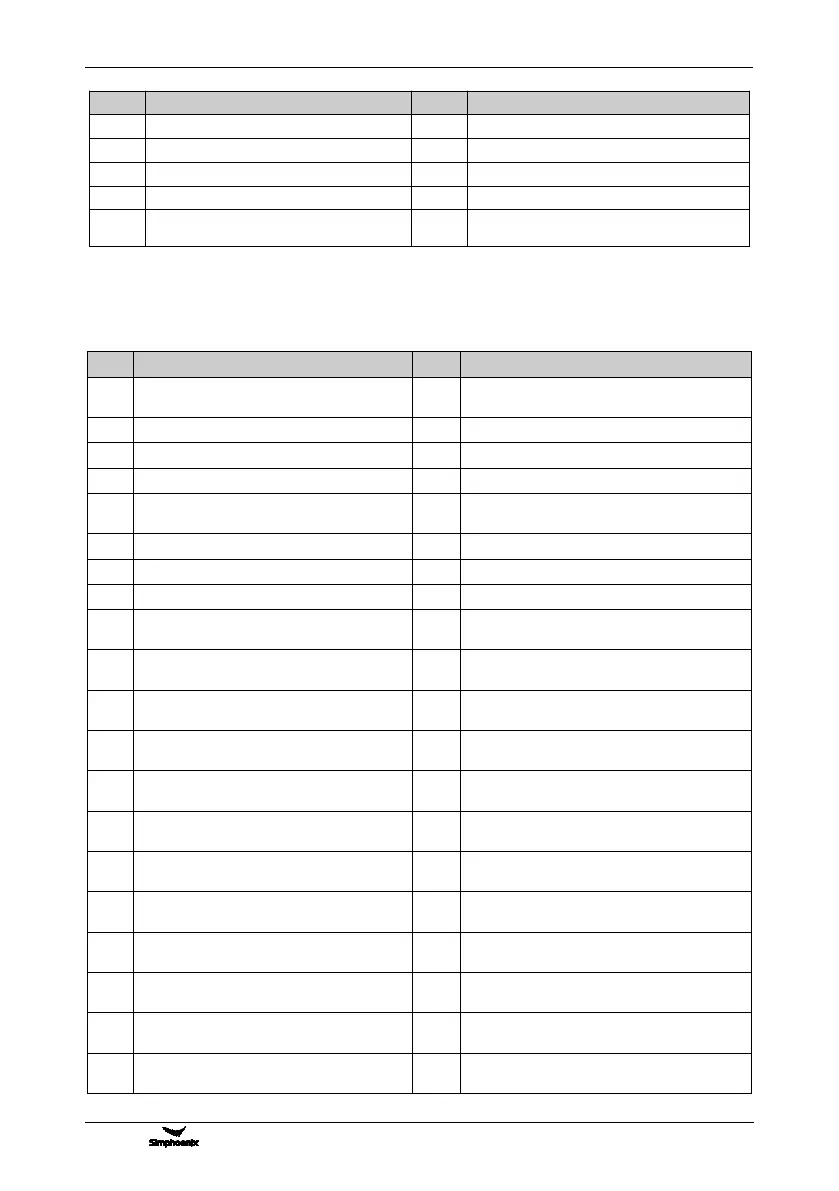

Functional Parameter Table

V800 Series High Performance Closed-Loop Vector Inverter User Manual

Spindle positioning selection 1

Spindle positioning selection 2

Spindle positioning selection 3

Servo command pulse value clear

0.1Hz~100.00KHz pulse input(DI9/Fin

Effective)

Pulse input(DI9/Fin Effective)

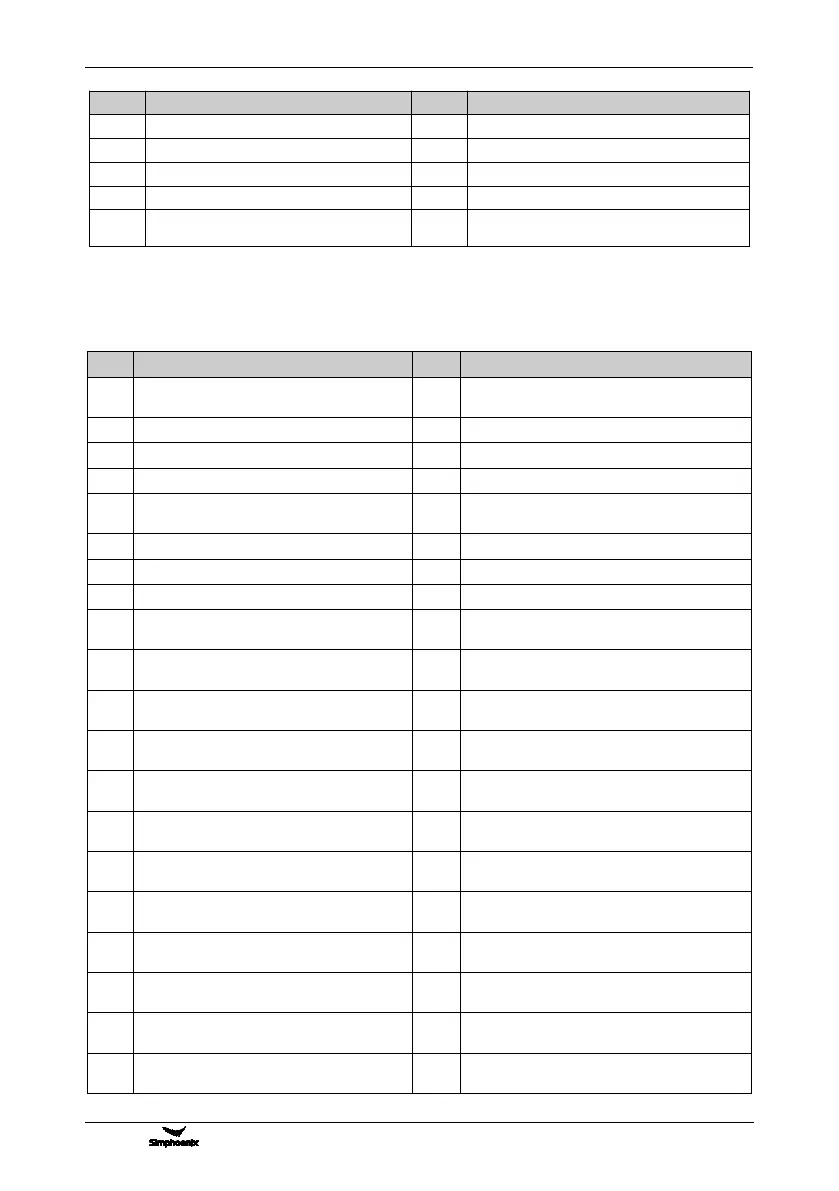

Table 2: Comparison Table of Multifunctional Output Terminal (DO/EDO/SDO)

Variables

Inverter running ready (normal voltage, no

emergency stop input)

Equipment normal (fault-free running)

Running command input (irrelevant with start

or running signal)

Inverter under voltage stop

Terminal control effective

In the process of acceleration running

In the process of deceleration running

Braking power generation running status

Determined by standard MODBUS Fieldbus

Determined by Extended communication

module

Completion of current stage of multi-stage

running (0.5s pulse )

Multi-stage running completed (0.5s pulse )

Multi-stage running completed (continuous level

output)

Multi-stage running cycle completed (0.5s

pulse )

Swing frequency upper and lower limit

Encoder direction positive (A pulse

surpassing B pulse )

Encoder direction negative (A behind B)

Monitor 1 input variable below the lower limit

(Void when above the upper limit)

Monitor 1 input variable above the upper

limit(void when below the lower limit)

Monitor 1 input variable between the upper

limit and the lower limit

Monitor 2 variable below the lower limit (void

when above the upper limit)

Monitor 2 input variable above the upper

limit(void when below the lower limit)

Monitor 2 input variable between the upper limit

and the lower limit

Monitor 3 input variable below the lower

limit(void when above the upper limit)

Monitor 3 input variable above the upper limit

(void when below the lower limit)

Monitor 3 input variable between the upper

limit and the lower limit

Position reached (Servo or spindle control)

Analog input AI1 wire breakage detection

effective

Analog input AI2 wire breakage detection

effective

Analog input AI3 wire breakage detection

effective

Loading...

Loading...