V/D

S

ERIES

M

ECHANICAL ASSEMBLIES

3-70 Revision: 2.1

results in the opposing movements of the scissor mechanism and the

locking shoe (see “Scissor mechanism”).

3.10.3 Maintenance tasks

Checking the pressure

Check that the pressure is set to 7 bar ± 1.

3.10.4 Checking the compressed air system for leaks

Compressor does not start!

If the compressor only starts at 1.5 – 2 bar and is very hot, then

the no-return valve R6 must be checked.

If the compressor starts running more frequently than every 5 minutes

after the pressure has been built up, check the compressed air system for

leaks in the following order:

Checking for leaks on the pneumatic assembly

Necessary tools Adapter for shutting off the compressed air

connections

Sample adapter:

Have available 4 mm Teflon hose (Systec item no. 10977)

T-connector (Systec item no. 11010)

Leak detection spray (Systec item no. 11922)

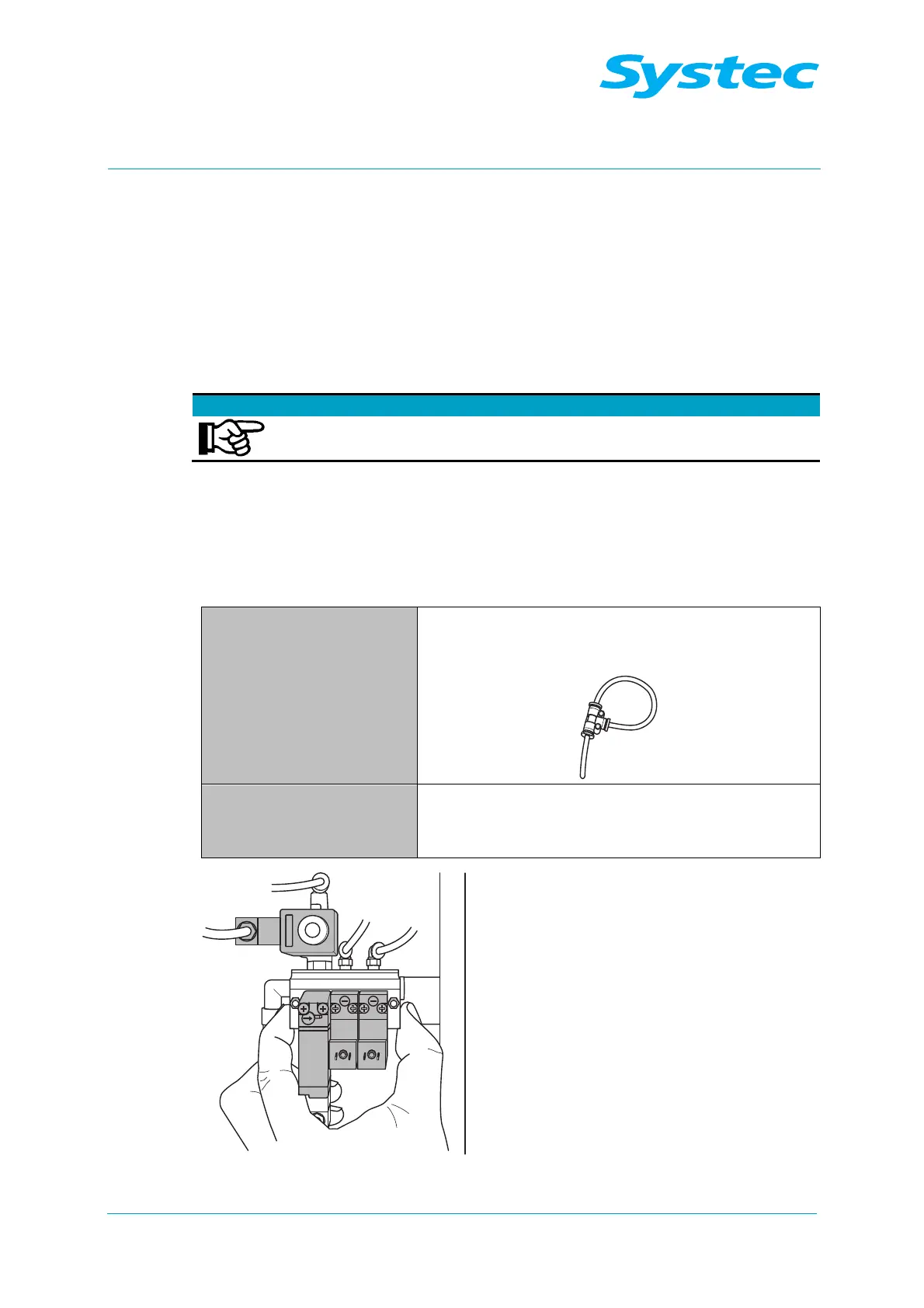

Fig. 37: Closing the release openings

Loading...

Loading...