V/D

S

ERIES

M

ECHANICAL ASSEMBLIES

Revision: 2.1 3-53

3.7 Cooling

3.7.1 Position and function

Water cooling with support air

Operating principle:

After the sterilisation phase has ended, the steam in the sterilisation

chamber is replaced with sterile, filtered, compressed air (support air) and

the cooling coil is flooded with cooling water. After the unloading

temperature is reached, the support air is vented and atmospheric

conditions are established.

The pressure reducer on the input for support air is factory set to 6 – 7 bar

and can be read from the manometer on the pressure reducer.

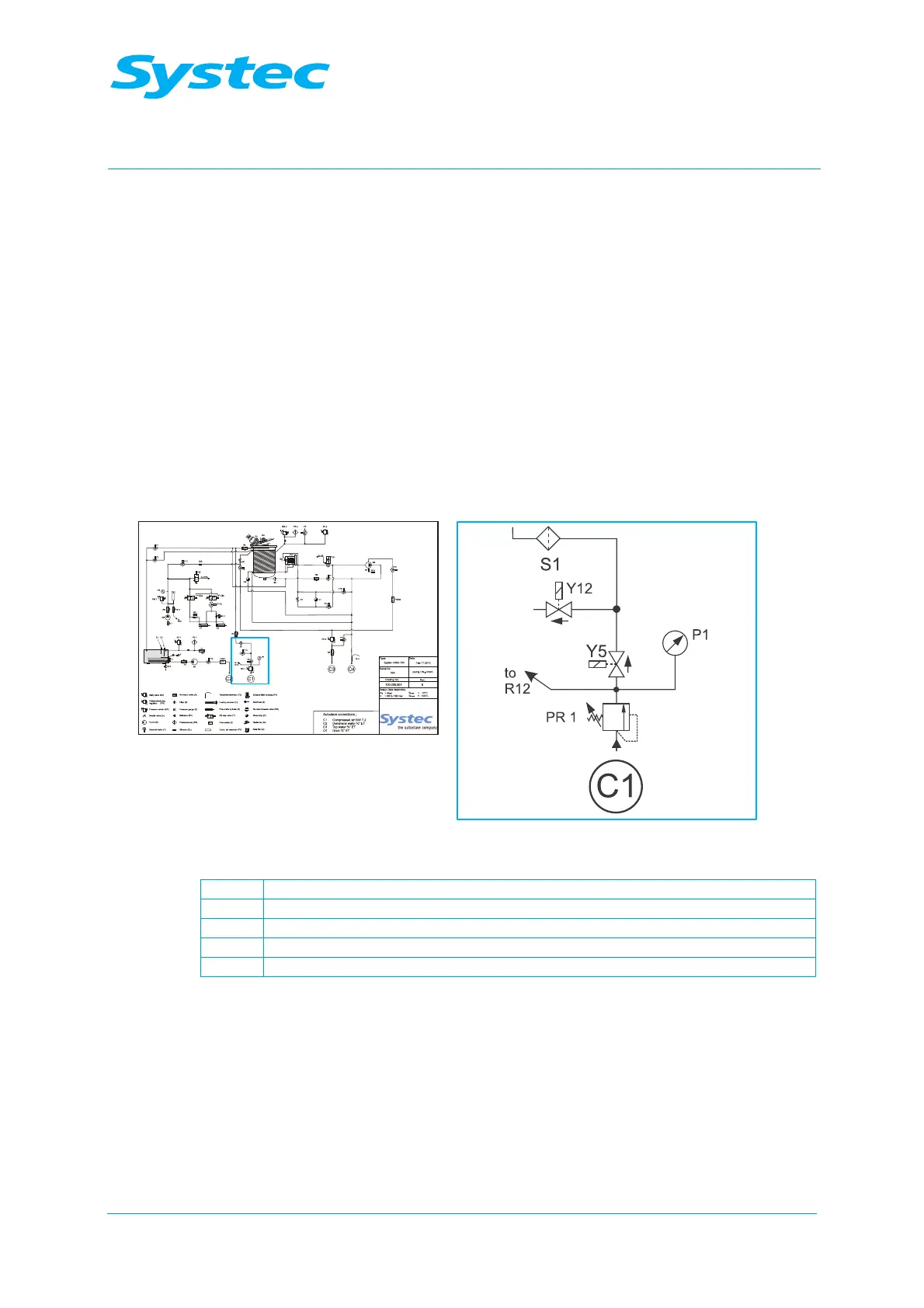

Fig. 30: Components on the “Cooling” assembly

P1 Manometer

PR1 Pressure reducer for support air

Y5 Support air valve

Y12 Vacuum breaker

S1 Sterile air filter

Water cooling:

The temperature of the unprocessed, cooling water in the cooling coil is

checked using parameter 40 (SaveWaterTemp). If the temperature

measured is greater than 40 °C, the cooling coil is supplied at the

maximum flow rate. If a lower temperature is measured, this is a sign that

the cooling water is no longer removing much energy. Pulsing the water

flow will then reduce the water usage, thus saving energy.

Loading...

Loading...