CFM-BL10Pro General instruction manual

15 / 87

A) Defects that can be detected nearly 100% (major defects)

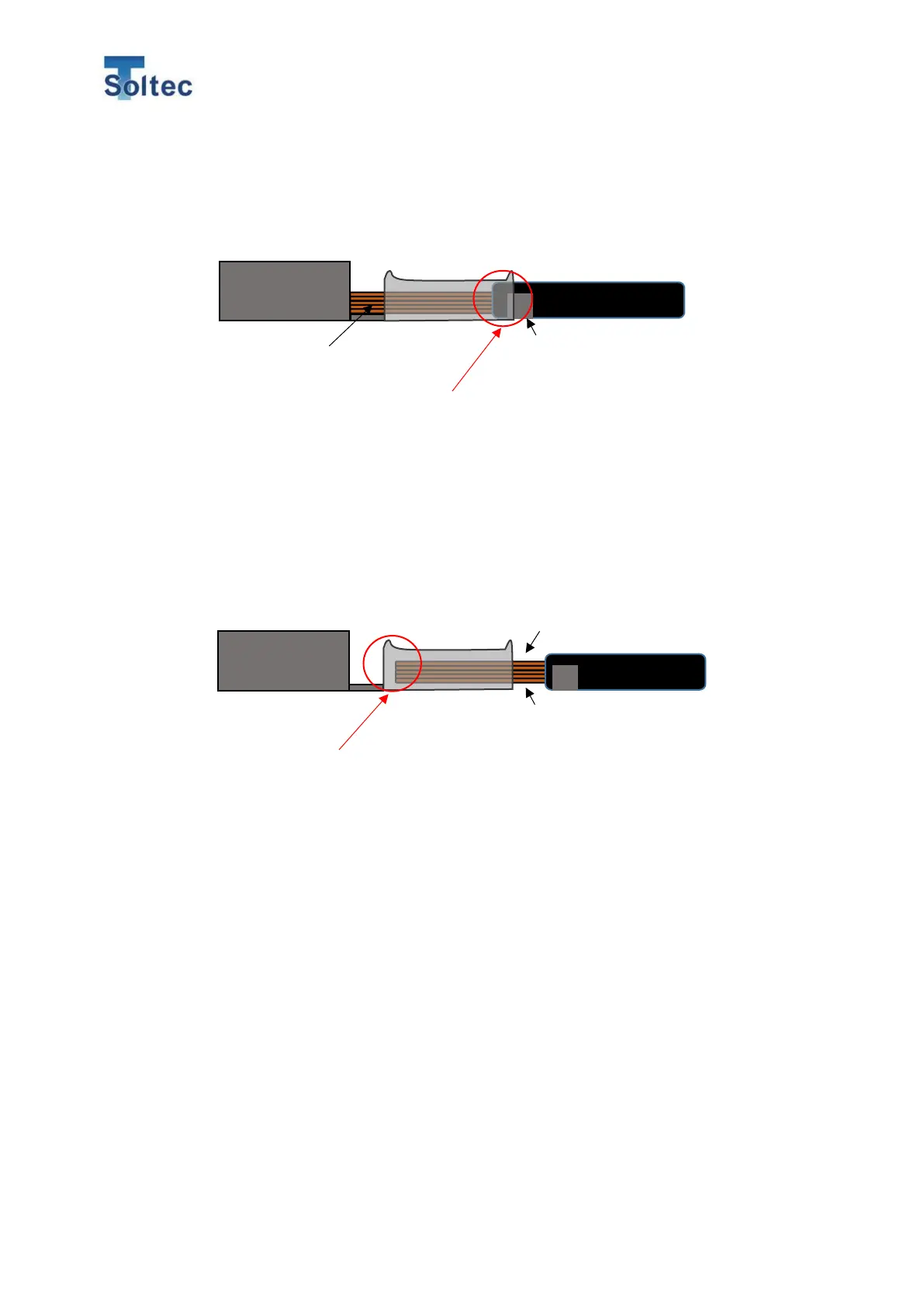

a) High feed (Wire barrel pinches the insulation)

This is the case where the wire barrel pinches the insulation (deep-feed defect). The

total force applied onto the wire barrel increases, which generates a change on the

crimping force curve. That’s why CFM can detect it.

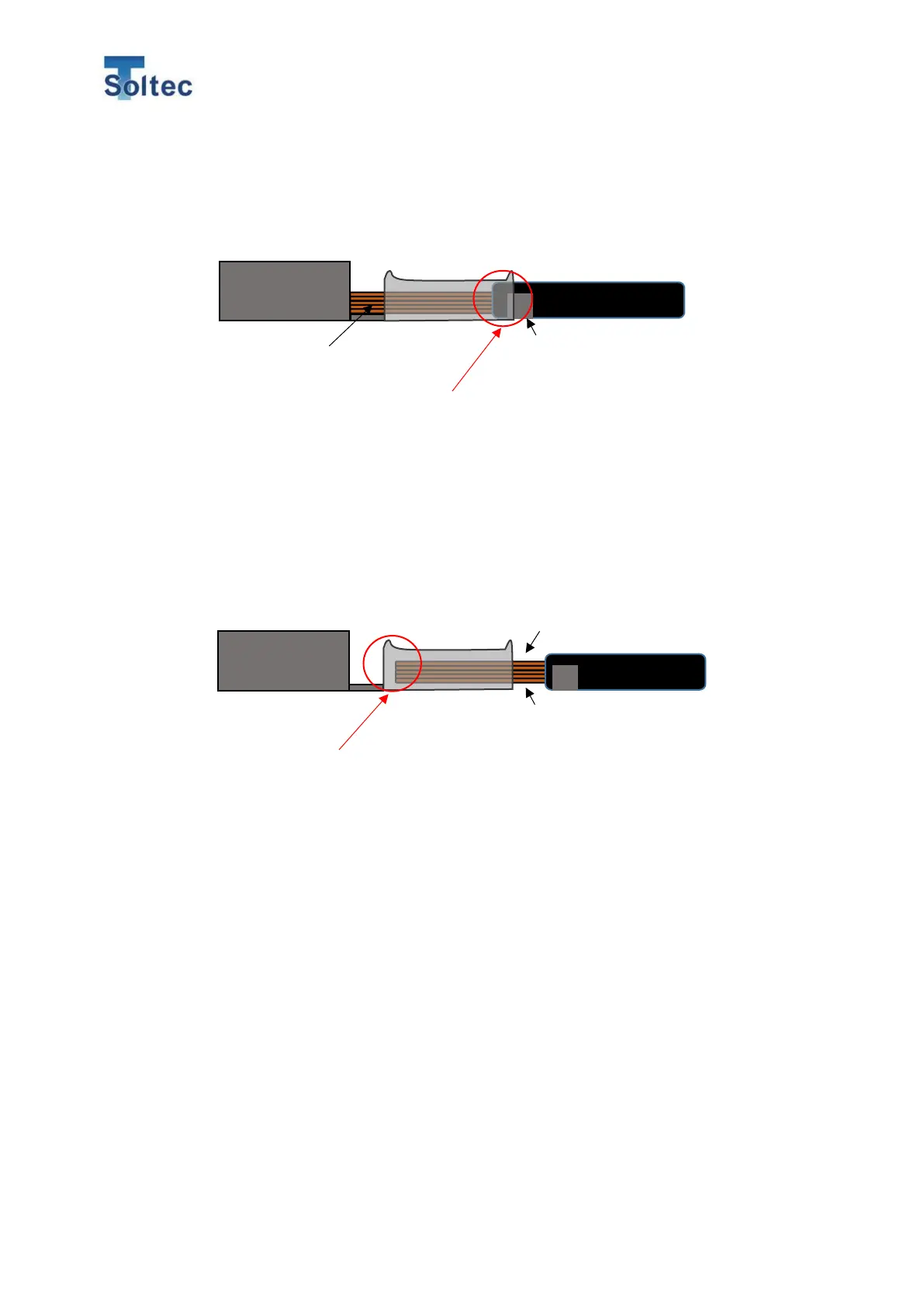

b) Low feed (Total volume of wire inside the wire barrel decreases)

This is the case where the wire top position is pulled down and stays inside the wire

barrel (low-feed defect). The total volume of wire inside the wire barrel decreases,

which generates a change on crimping force curve. Therefore, CFM can detect it.

Fitting part

Example of high feed (detectable)

Fitting part

Example of low feed (detectable)

Loading...

Loading...