CFM-BL10Pro General instruction manual

16 / 87

B) Defects that are difficult to detect

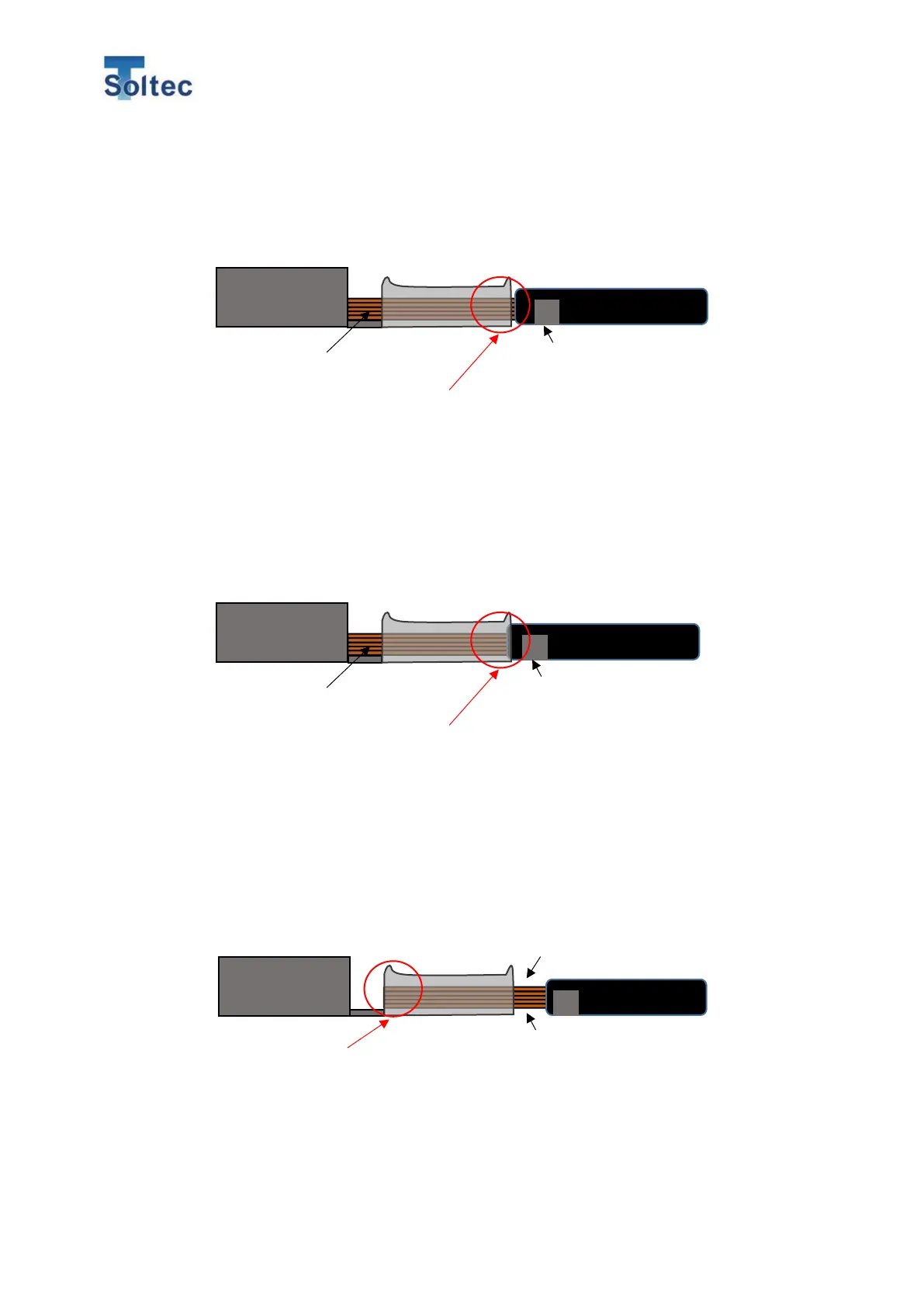

a) High feed (Wire barrel does not pinch the insulation)

This is the case where the wire barrel does not pinch the insulation (deep-feed

defect). The total force applied onto the wire barrel does not change, which means

the crimping force curve does not change either. That’s why it is difficult to detect.

b) High feed (The insulation is under the bell mouth, but not pinched by the wire

barrel)

This is the case of deeper feed than usual. The insulation looks like being under the

bell mouth. It seems easy to detect this kind of deep feed, but the insulation is not

pinched into the wire barrel. In this case, the total force applied onto the wire barrel

does not change. Neither do the crimping force curve. That’s why it is difficult to

detect.

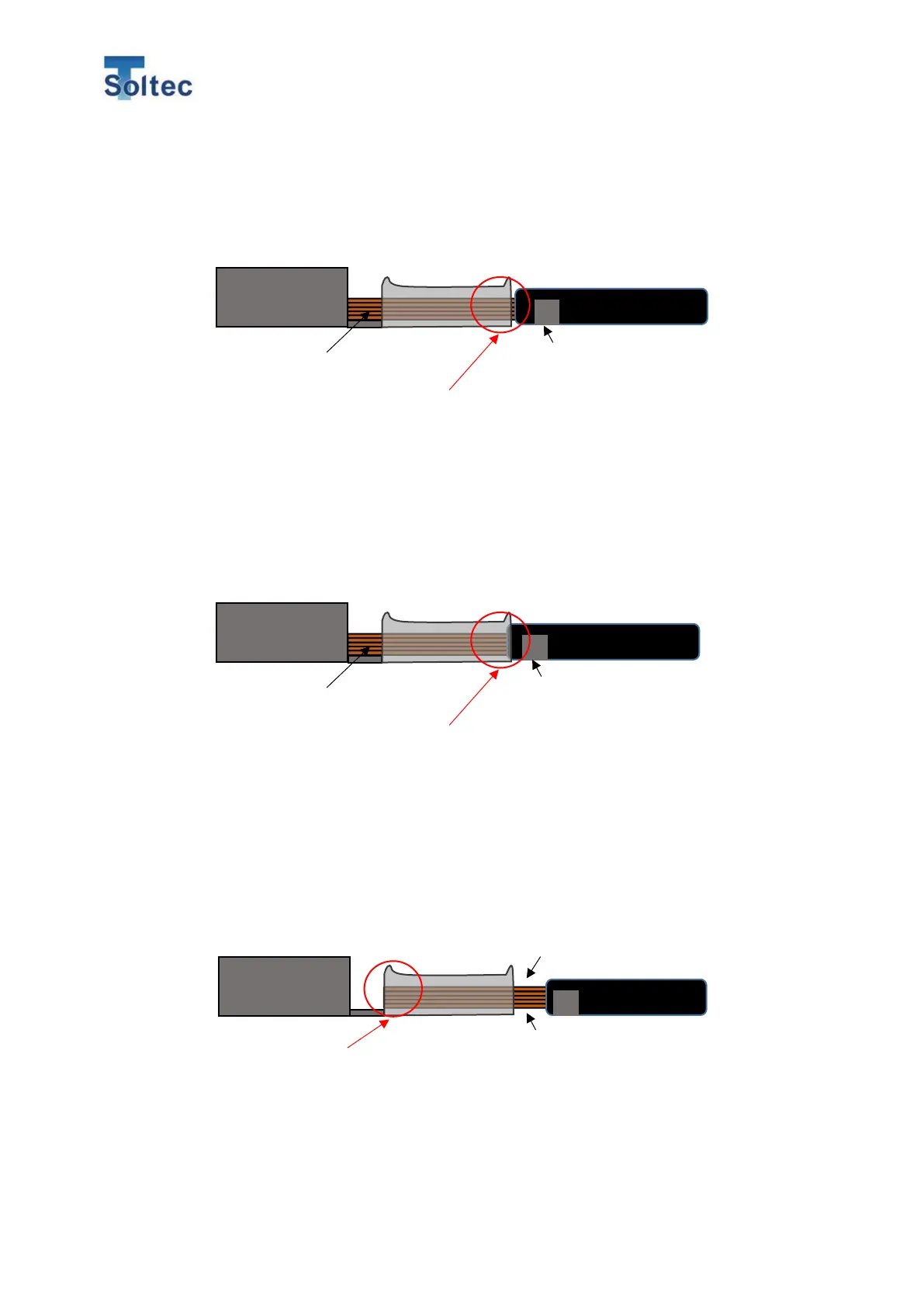

c) Low feed (The total volume of wire inside the wire barrel does not decrease)

This is the case of lower feed than usual. The wire top does not appear between the

wire barrel and the fitting part window. It seems easy to detect this type of low feed.

However, as shown in the above picture, if the total volume of wire inside the wire

barrel stays the same, so does the total crimping force. That means the curve also

does not change, which is very hard to detect.

Example of deep feed (hard-to-detect case)

Example of deep feed (hard-to-detect)

Fitting part

Example of low feed (hard-to-

Loading...

Loading...