3-42 Engine Electrical Industrial 1.6L

Voltage Regulator

The integral voltage regulator protects the unit’s

operating accessories from receiving high voltage and

the battery from being overcharged. No current

regulation is needed because it determined by the

design of the generator.

The regulator is an extremely reliable device composed

of two circuits. One of these circuits is used to sense

voltage and control the other circuit which cycles the

field current “on and off” to prevent voltage from going

to high.

The regulator limits system voltage by controlling the

rotor field current. When the field current is on, the

regulator switches the rotor field on and off at a fixed

rate of about 400 cycles per second. By varying the

overall on/off time, correct average field current for

proper system voltage control is maintained. At high

speeds, the on time may be 10 percent and the off time

may be 90 percent. At low speeds, and with high

electrical loads, the on/off time may be 90 percent and

10 percent respectively.

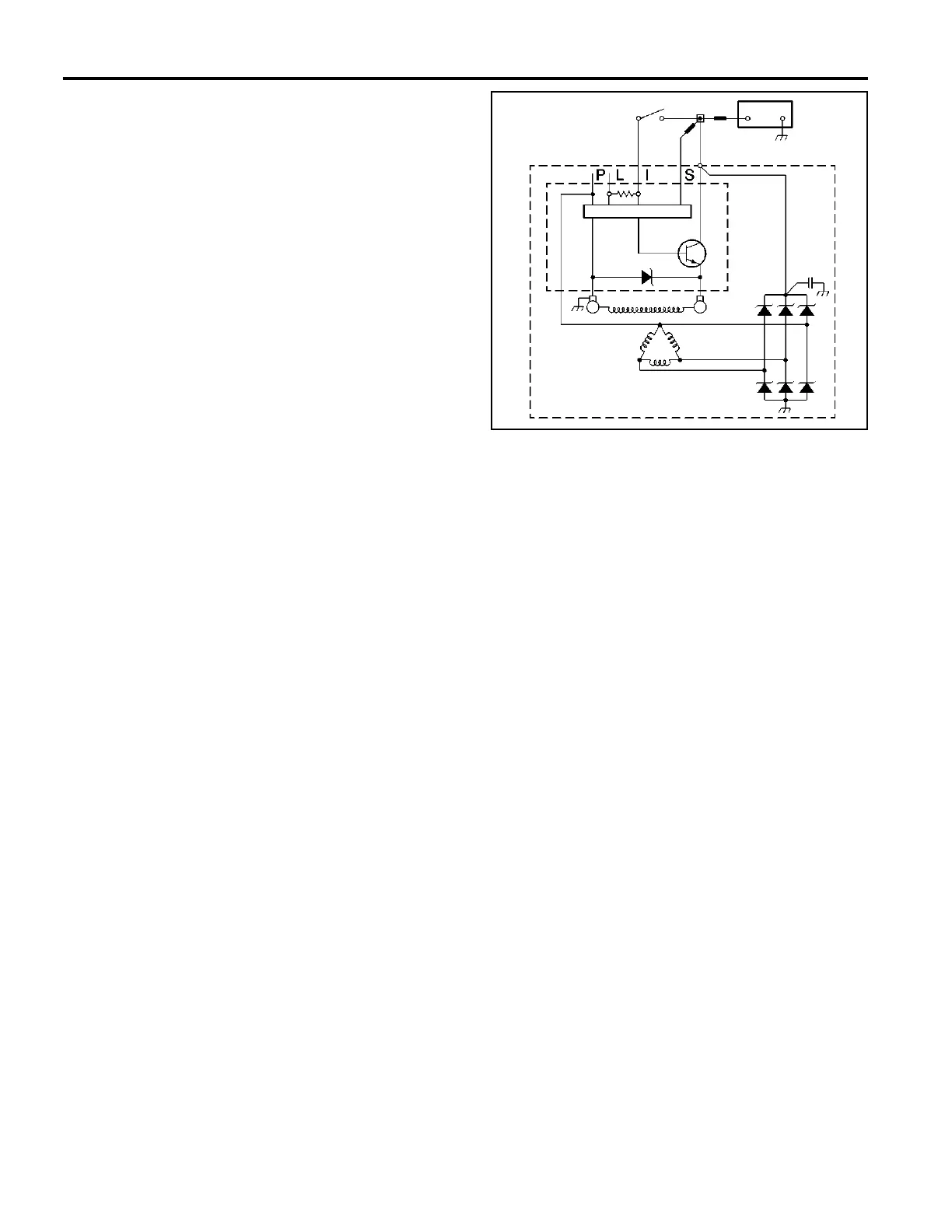

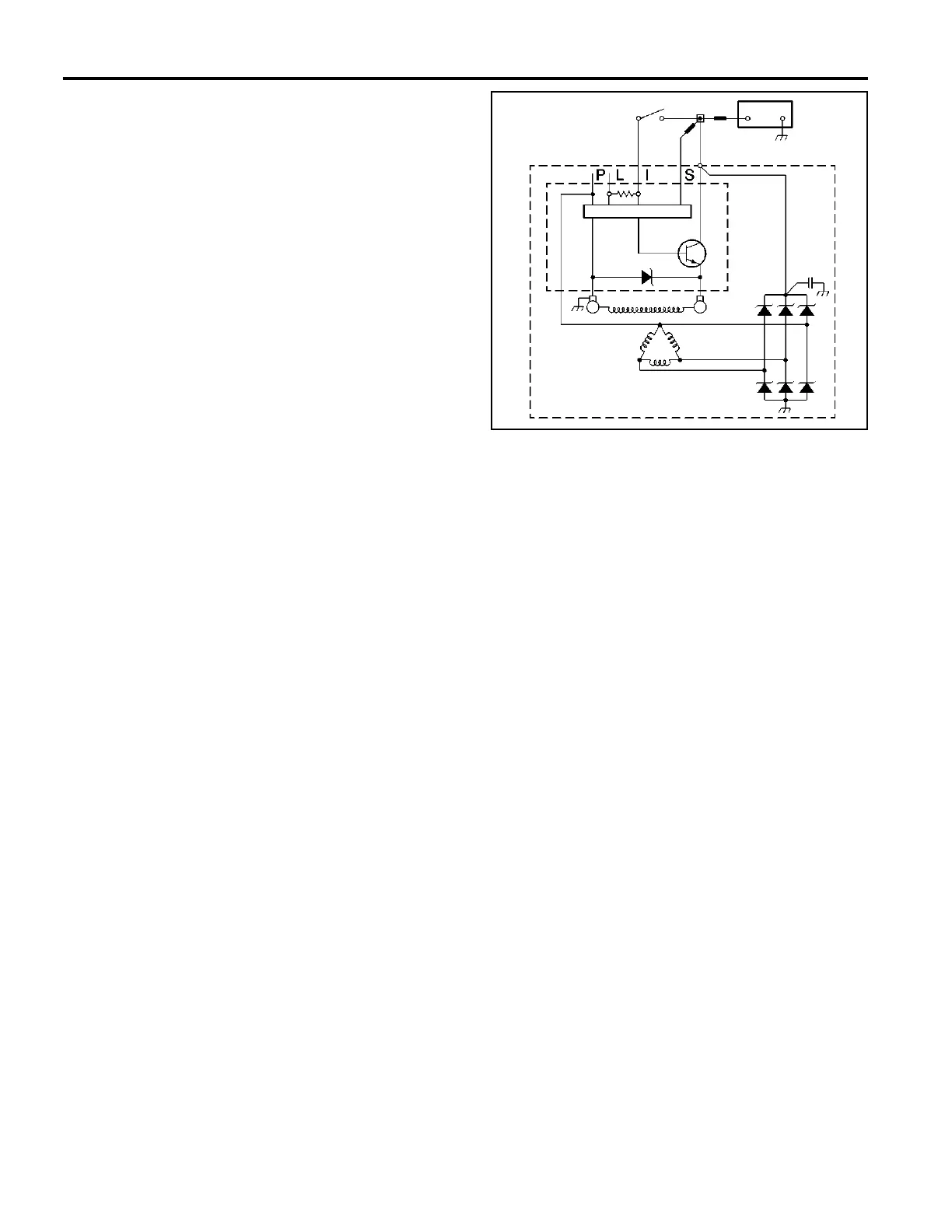

The regulator has four terminals, The terminals are P,

L, I, and S. These letters are stamped on the regulator.

Generally, in SI generators the S terminal senses the

state of the battery and allows field current flow when

the switch is closed.

When the battery voltage rises to predetermined level,

the sensing circuit tells the regulator to turn OFF. This

decreases the magnetic field around the field coil and

generator voltage is limited to a safe value.

When the battery voltage drops below a predetermined

level, the sensing circuit tells the regulator to turn ON.

This increases the magnetic field around the field coil

and generator voltage begins to charge the battery.

Charging System Circuit Description

The generator provides voltage that operates the

electrical system of the vehicle and that also charges

the battery and the secondary battery. A magnetic field

is created when current flows through the rotor. The

field rotates as the rotor is driven by the engine,

creating an AC voltage in the stator windings. The

rectifier bridge converts the AC voltage to DC and this

goes to the electrical system at the terminal to the

battery.

The digital regulator of the generator uses digital

techniques in order to supply the rotor current. Be-

cause of this, the digital regulator controls the output

voltage. The rotor current is proportional the width of

the electrical pulses supplied from the electrical system

through the RED wire connected between the battery

and S terminals on the generator .

When the ignition switch is turned to the RUN position,

current from the battery flows through the closed

contacts of the switch, to the voltmeter gauge on the

instrument panel, the voltage regulator, and through the

field coil of the generator rotor.

With current applied to the digital regulator, the regula-

tor turns on. Narrow width pulses go to the digital rotor

circuit, creating a weak magnetic field. When the

engine starts, the digital regulator senses the rotation

of the generator by detecting AC voltage at the stator

through an internal wire. Once the engine is running,

the digital regulator varies the field current by control-

ling the pulse width. This regulates the output voltage of

the generator for proper charging of the battery and

operation of the electrical system.

375662

Loading...

Loading...