Industrial 1.6L Engine Mechanical 1-19

Inspect

1. Air outlet at: inlet or exhaust side, compensation tank

and crankcase housing. Max. difference in pressure be-

tween individual cylinders: 10%. The max. pressure loss

of a cylinder should not exceed 25%.

2. Check pressure loss at 3rd, 4th and 2nd cylinders analo-

gously. Bring piston of cylinder to be checked in ”ign.

TDC” position, ignition sequence: 1–3–4–2.

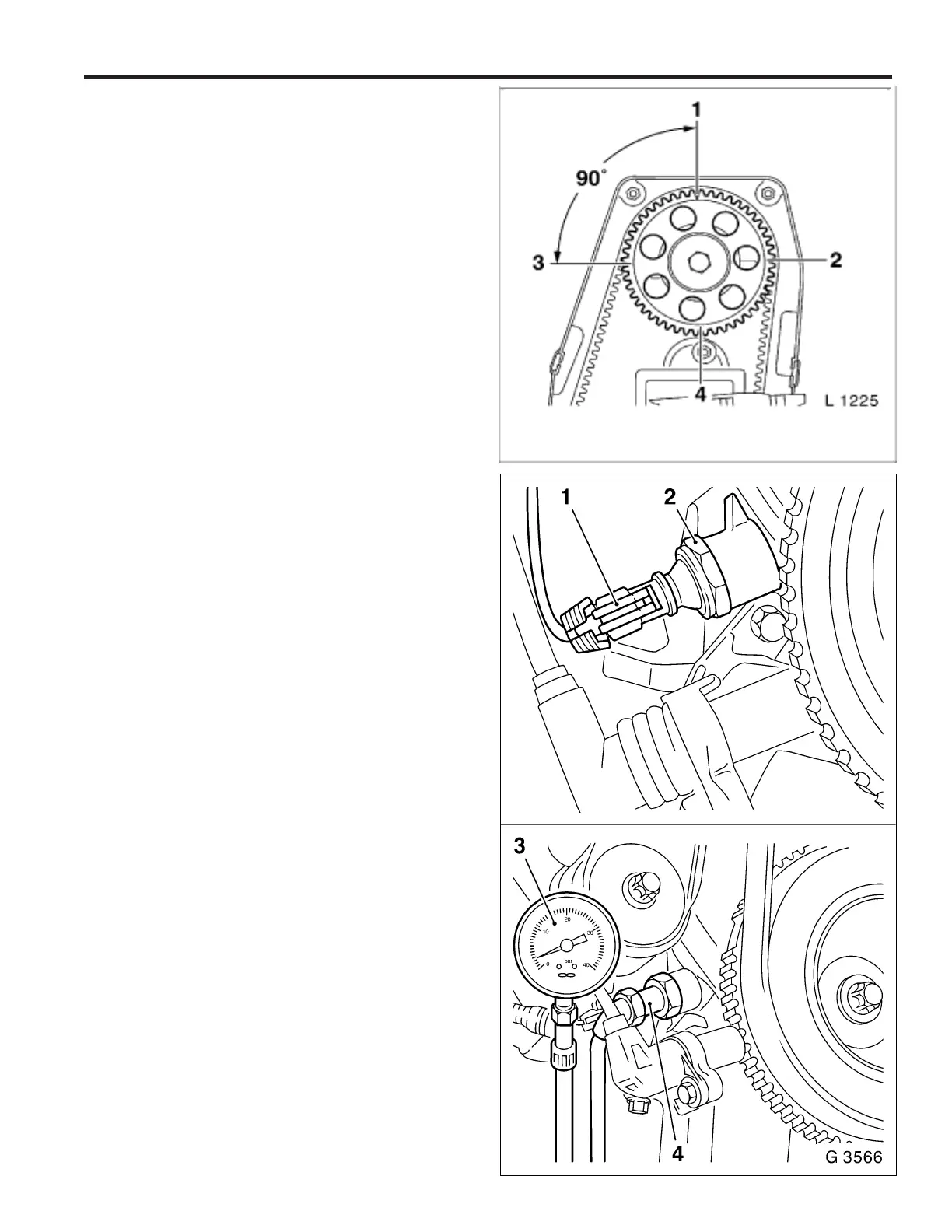

3. Determine ”ign. TDC” position by placing guide marks on

camshaft sprocket.

4. Further turn crankshaft 180° in engine rotational direction

(corresponds to 90° at camshaft sprocket) up to cam-

shaft sprocket guide mark and align toothed belt cover.

5. Determine the ”ign. TDC” position for 4th and 2nd cylin-

ders analogously. Turn crankshaft slowly and uniformly.

Installation Procedure

1. Install upper part of toothed belt cover – see operation

Toothed Belt Cover – Upper Part, Remove and Install.

2. Install park plugs in cylinder head using KM–194–E.

Tighten

Tightening torque of spark plugs is 25 Nm / 18.5 lb. ft.

3. Attach spark plug connector, fluid filler opening sealing

cap, coolant compensation tank sealing cap and oil dip

stick.

Oil Pressure Check

Removal Procedure

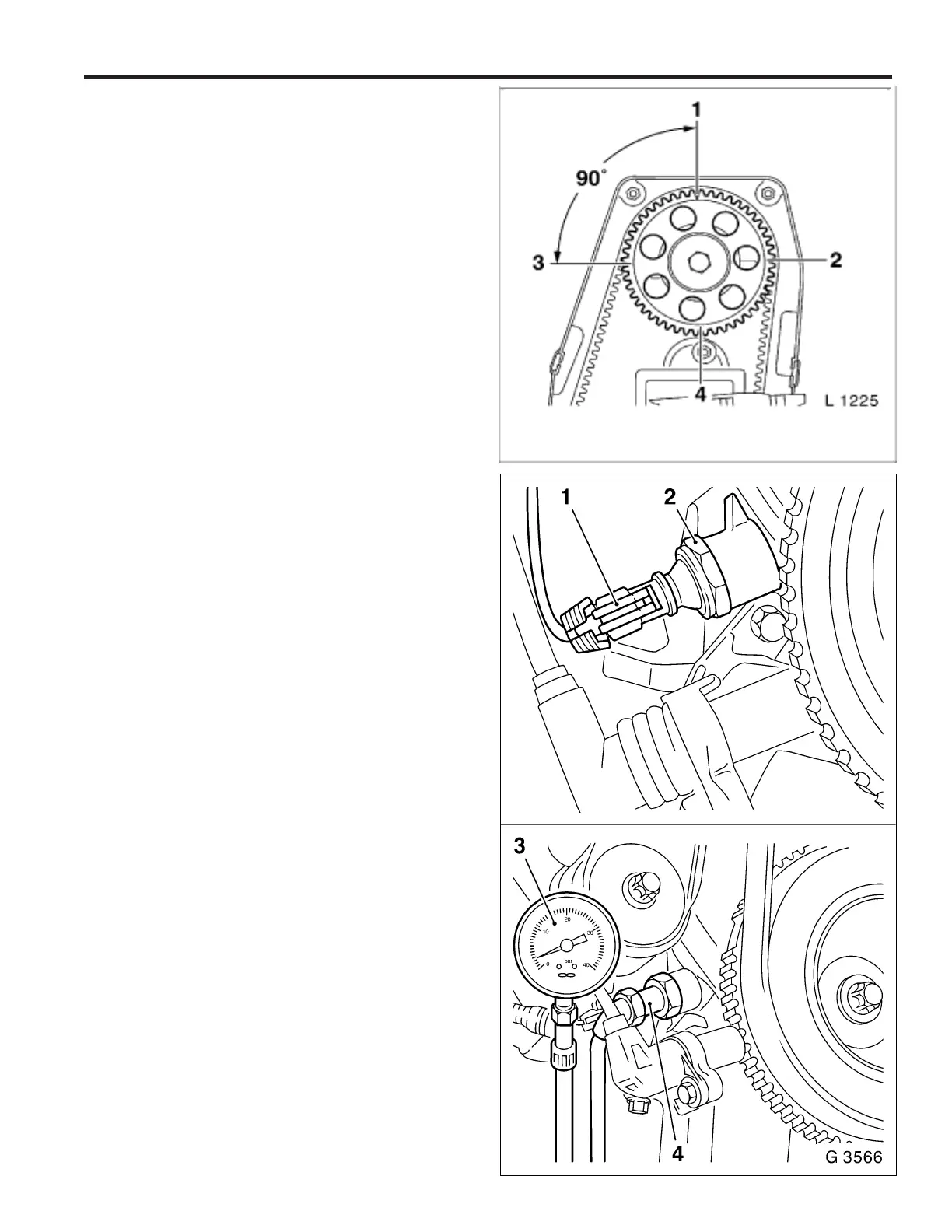

1. Disconnect wiring harness plug (1) from oil pressure

switch, remove oil pressure switch (2) – place collecting

basin underneath.

Inspect

1. Check oil pressure with KM–498–B (3) and KM–135 (4).

The oil pressure should be approx. 150 kPa (1.5 bar) at

idling speed with an oil temperature of 80 °C.

Installation Procedure

1. Attach oil pressure switch to oil pump with new seal ring.

Tighten

Tightening torque 30 Nm / 22 lb. ft.

2. Connect wiring harness plug to oil pressure switch.

3. Check engine oil level and correct if necessary.

Loading...

Loading...