1-68 Engine Mechanical Industrial 1.6L

Crankshaft, Remove and Install

Removal Procedure

1. Remove engine – see operation Engine, Remove and

Install.

2. Mount engine with Adapter KM–412–10–A on Assembly

Stands KM–412.

3. Remove oil pan – see operation Oil Pan, Remove

and Install.

3. Remove oil pump – see operation Oil Pump, Remove

and Install.

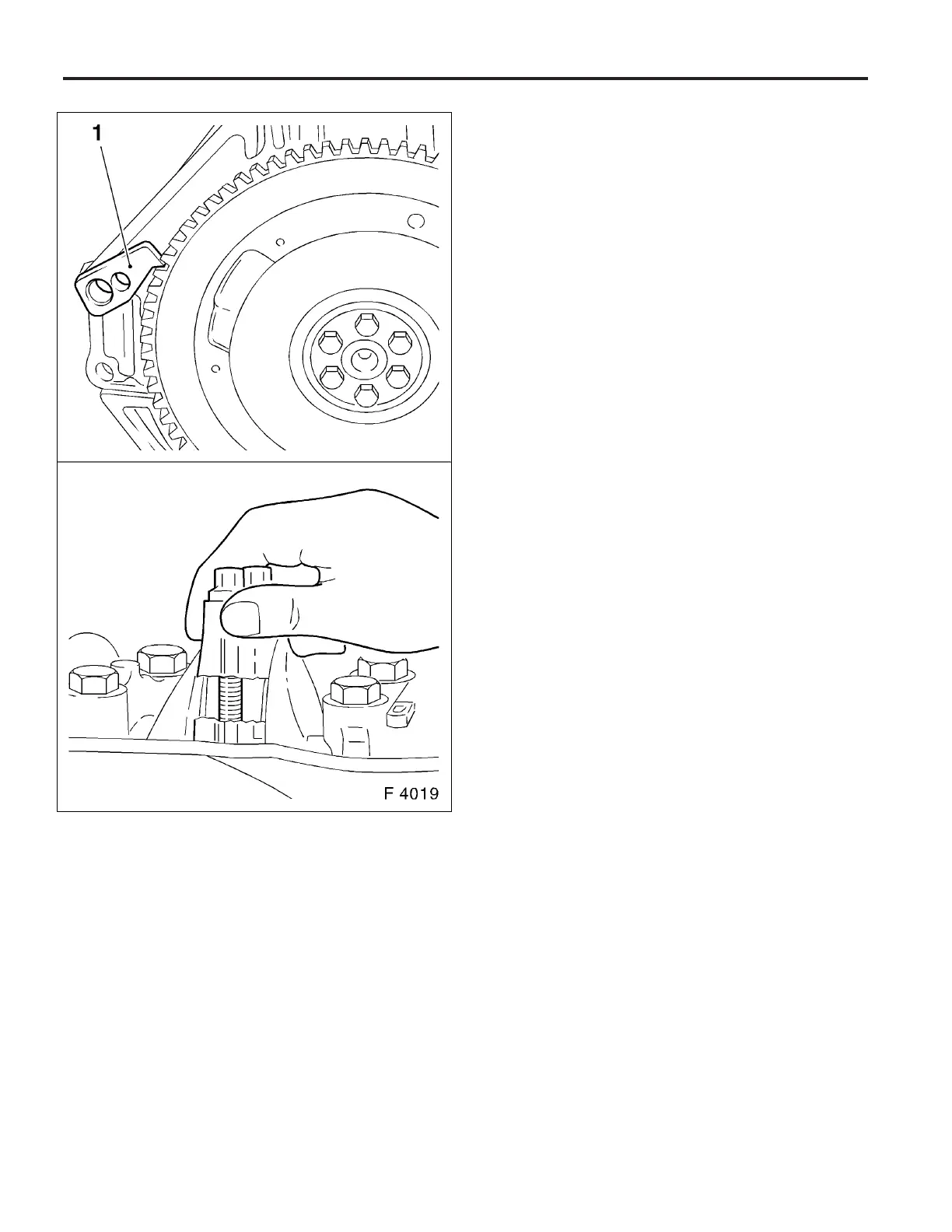

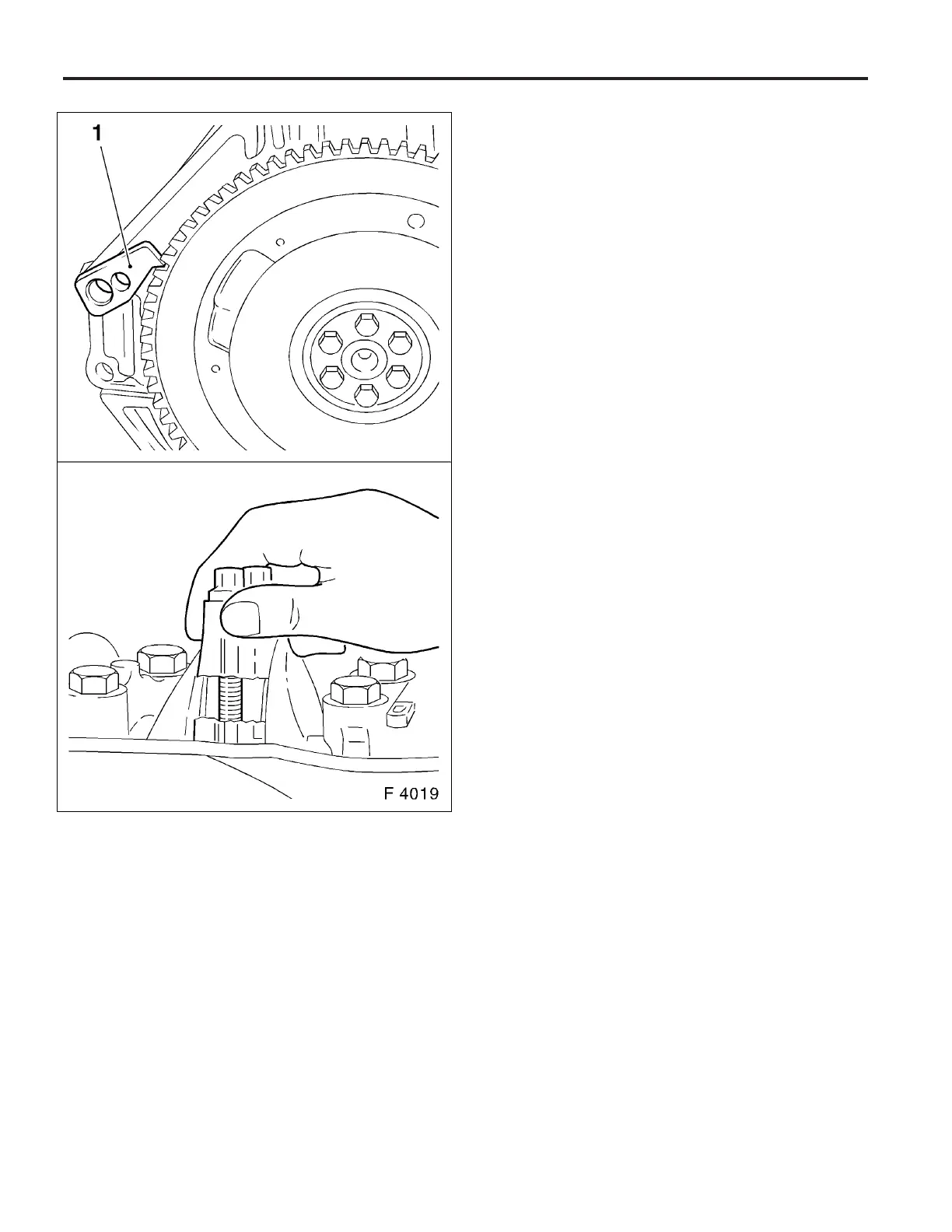

4. Lock flywheel or drive disc with KM–652 (1) and remove

from crankshaft.

Important: Mark order of con–rod bearing caps. Remove

con–rod bearing cap from conrod. The mating surfaces of

the cod–rods and the con–rod bearing caps form an

individual fit and as a result must not be damaged or

replaced under any circumstances. Do not lay con–rods

and con–rod bearing caps on mating surfaces in order to

avoid damage.

Loading...

Loading...