Industrial 1.6L Engine Mechanical 1-69

Removal Procedure

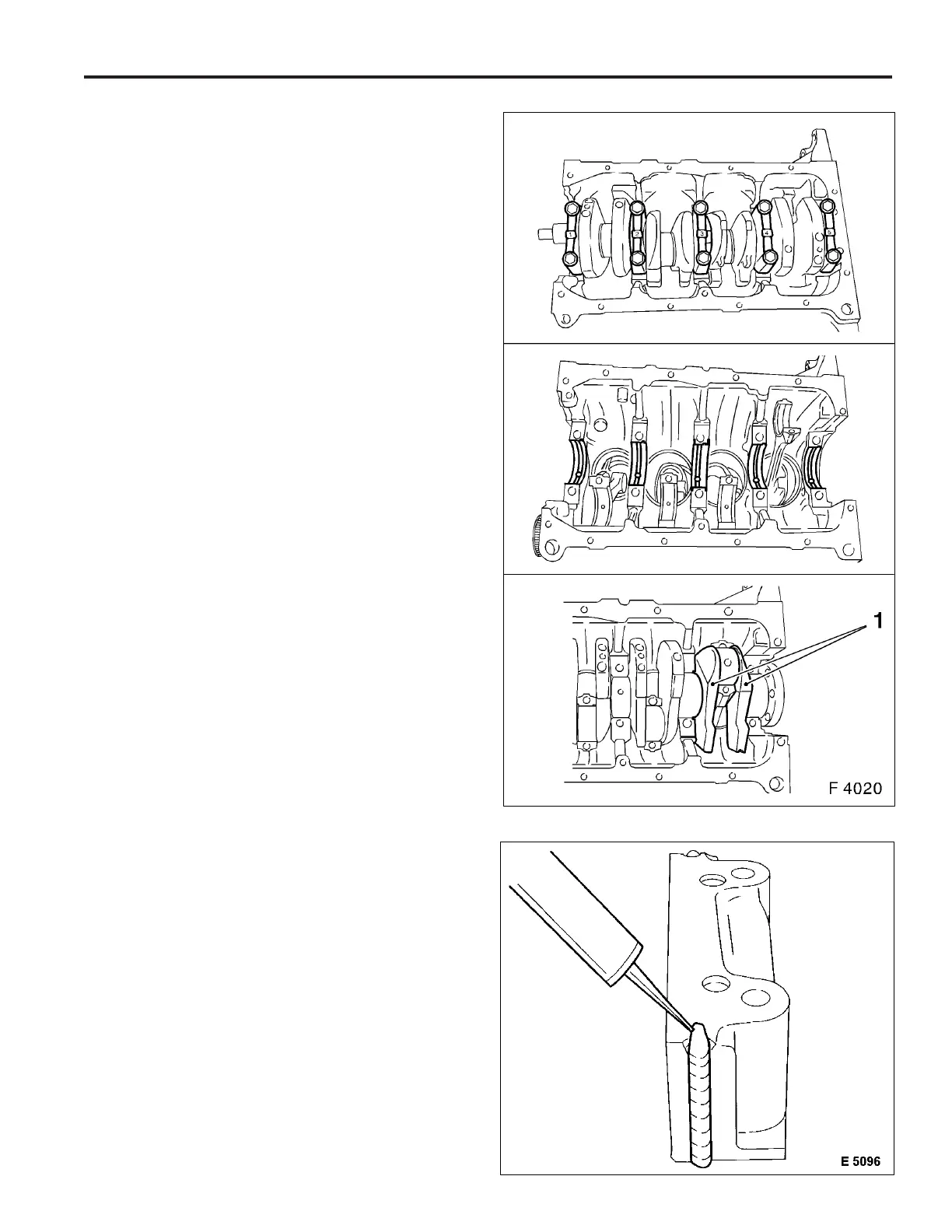

1. Identify sequence of crankshaft bearing caps.

2. Remove crankshaft bearing caps from cylinder block.

3. Remove crankshaft from cylinder block.

Clean

1. Clean all parts.

Inspect

1. Check crankshaft – see operation Crankshaft, Check.

Installation Procedure

1. Coat new bearing shells with engine oil and insert in

cylinder block and bearing cap.

2. Insert crankshaft carefully in cylinder block. Seat of crank-

shaft can be corrected by lightly tapping on crankshaft

webs (1) with rubber hammer.

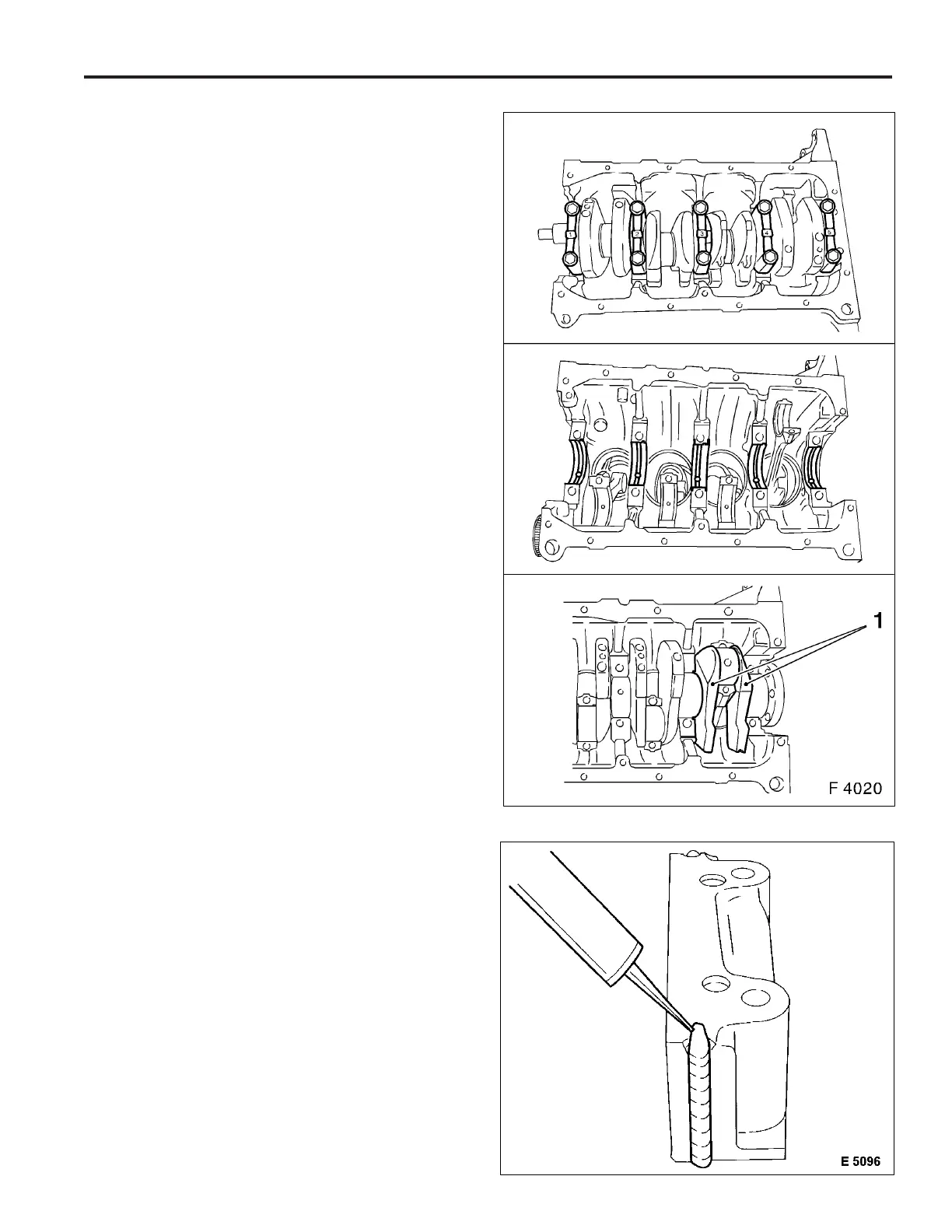

3. Apply a bead of adhesive sealing compound (black) to

grooves of rear crankshaft bearing cap. Install crankshaft

and con–rod bearing cap.

Note marks and installation position.

4. Crankshaft bearing cap to cylinder block.

Tighten

Tightening Torque 50 Nm / 37 lb. ft + 45° +15°.

5. Con–rod bearing cap to con–rod.

Tighten

Tightening torque 25 Nm / 18.5lb. ft. + 30°

6. Install crankshaft rear seal ring – see operation Seal

Ring, Crankshaft, Rear Replace.

7. Lock flywheel or drive disc with KM–652.

8. Install flywheel with new bolts to crankshaft.

Tighten

Tightening torque 35 Nm / 26 lb. ft. + 30° + 15°.

9. Install drive disc with new bolts to crankshaft.

Tighten

Tightening torque 55 Nm / 41 lb. ft. + 30° + 15°.

10. Install oil pump – see operation Oil Pump, Remove and

Install.

11. Remove engine from Overhaul Stand KM–412 and re-

move Adapter KM–412–10 from engine. Install engine –

see operation Engine, Remove and Install.

Important: Use new bolts. After assembly of bearing cap,

press in adhesive sealing compound (black) from above again

until adhesive sealing compound (black) escapes from the

joints.

Loading...

Loading...