Industrial 1.6L Engine Mechanical 1-17

Diagnostic Information and Procedures

Ribbed V–belt Tension, Check

Drive belts must grip the entire contact area of the pully.

When drive belts are too loose, the belts can slip, tear,

burn, or grab and snap. More belts fail from being too

loose than too tight.

Belts that are too tight can damage the engine by causing

side loading of the crankshaft, crankshaft bearings, and

accessories or accessory bearings. Too much belt

tension will also stretch and weaken the belt.

When the drive belts are worn, they should be replaced.

Tightening worn drive belts will not prevent slipping, and

can also cause damage to the engine.

Do not use belt dressings to extend belt life. Most

dressings contain chemicals which soften the belt.

Tools Required:

••

••

• 6” Steel Rule

Engine Compression Test

Removal Procedure

1. With engine at operating temperature (oil temperature

80 °C), detach spark plug connectors and remove spark

plugs with KM–194–E.

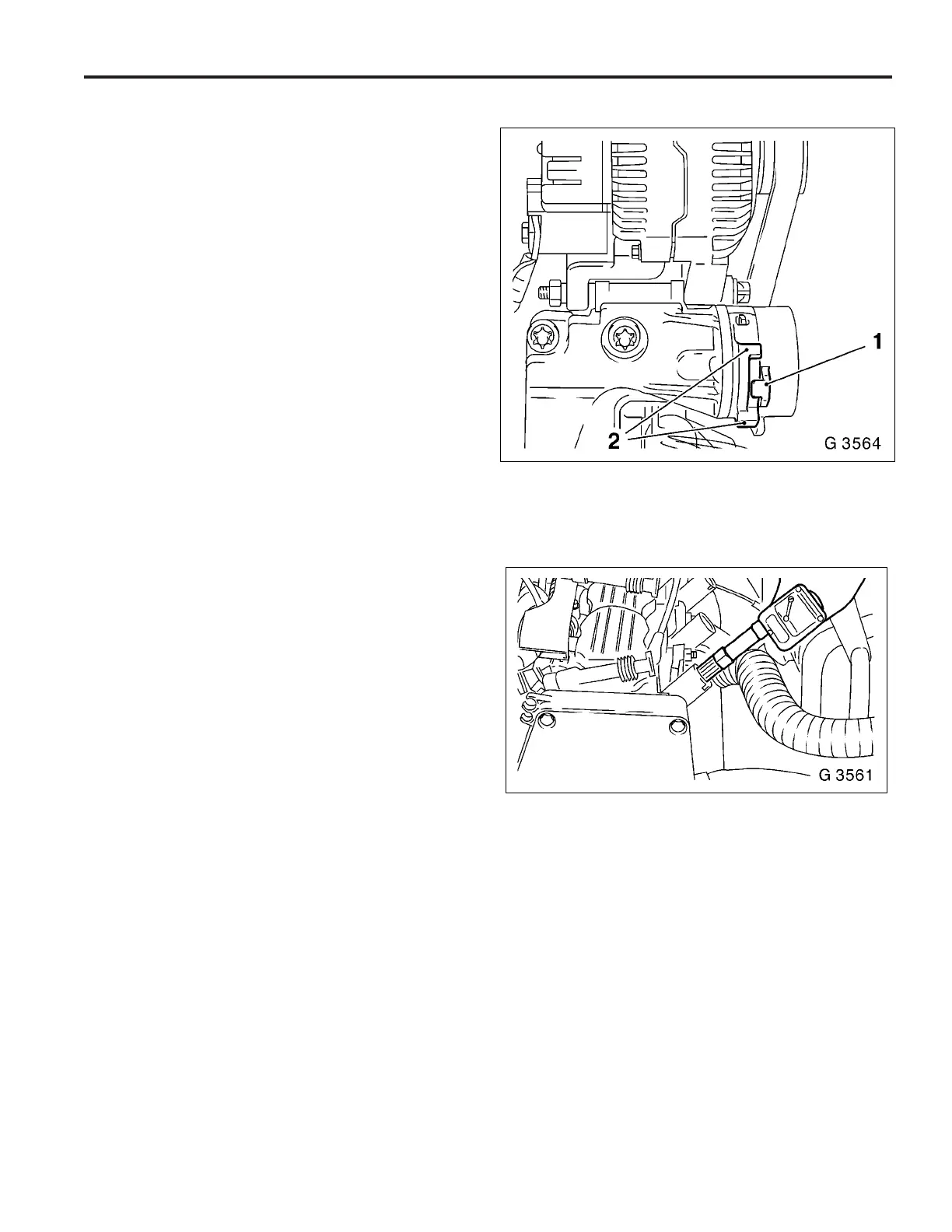

2. Detach wiring harness plug (1) from DIS ignition mod-

ule.

3. Open relay holder cover and pull fuel pump relay (2) out

of base.

Inspect

1. Use compression recorder with rubber cone and a mea-

suring range of up to 1750 kPa (17.5 bar) overpressure.

2. Actuate starter for approx. 4 seconds with throttle valve

fully open – minimum engine speed 300 rpm. The pres-

sure difference between the individual cylinders should

not exceed 100 kPa (1 bar).

1. Inspect the drive belt for:

• Cracks

• Glazing

• Tears or cuts

• Excessive wear

2. Measure the amount of play in the belt. The fan belt

should measure approximately 1/2 inch (13 mm) deflec-

tion.

Loading...

Loading...