1-18 Engine Mechanical Industrial 1.6L

Installation Procedure

1. Insert fuel pump relay in base and close relay holder

cover.

2. Connect wiring harness plug to DIS ignition module.

3. Install spark plugs with KM–194–E into cylinder head –

Tighten

Tightening torque 25 Nm / 18 lb. ft.

4. Connect spark plug connectors.

Engine Loss of Compression Test

Engine at operating temperature (oil temperature 80 °C).

Removal Procedure

1. Detach spark plug connectors, remove spark plugs with

KM–194–E.

2. Remove fluid filler opening sealing cap, coolant com-

pensation tank sealing cap and oil dipstick.

3. Remove upper part of toothed belt cover – see operation

Toothed Belt Cover – Upper Part, Remove and Install.

Adjust

1. Set piston of 1st cylinder to TDC position. To determine

TDC position – see operation Timing Check.

Installation Procedure

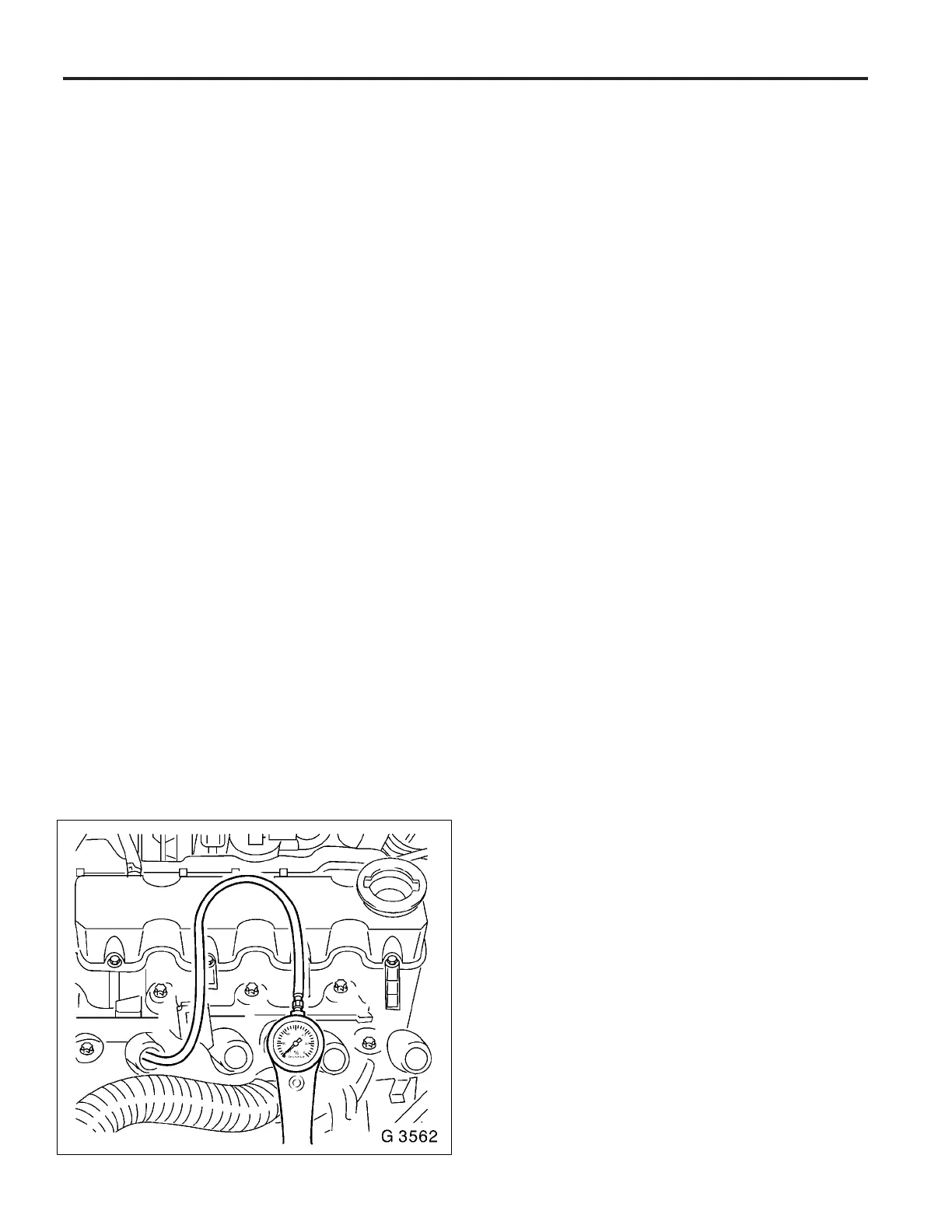

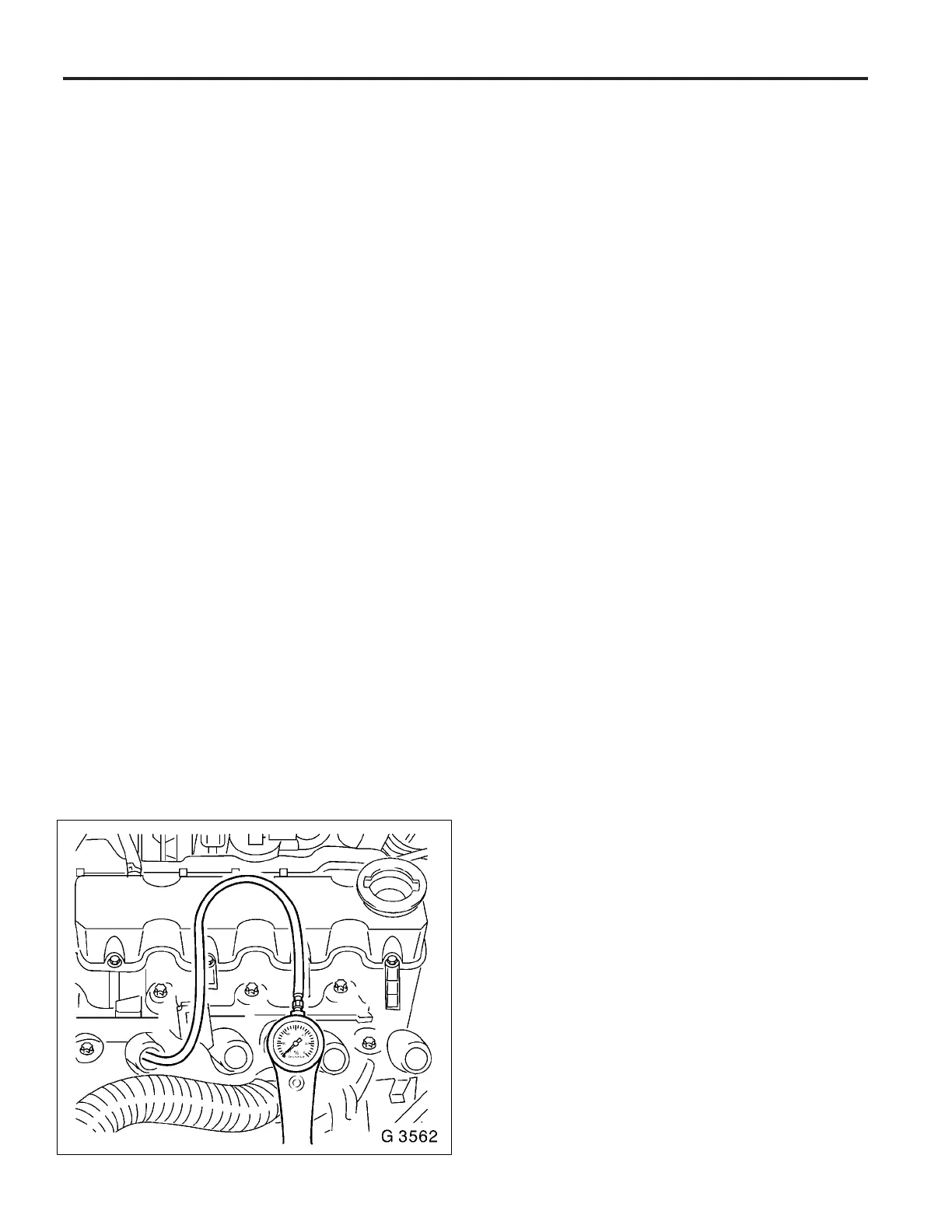

1. Connect pressure loss tester to compressed air system

and calibrate.

2. Screw connector into spark plug bore of 1st cylinder and

connect pressure loss tester with connector (observe

manufacturer’s instructions).

Important: The crankshaft is not permitted to rotate

during the test procedure.

Loading...

Loading...