1-66 Engine Mechanical Industrial 1.6L

Measure

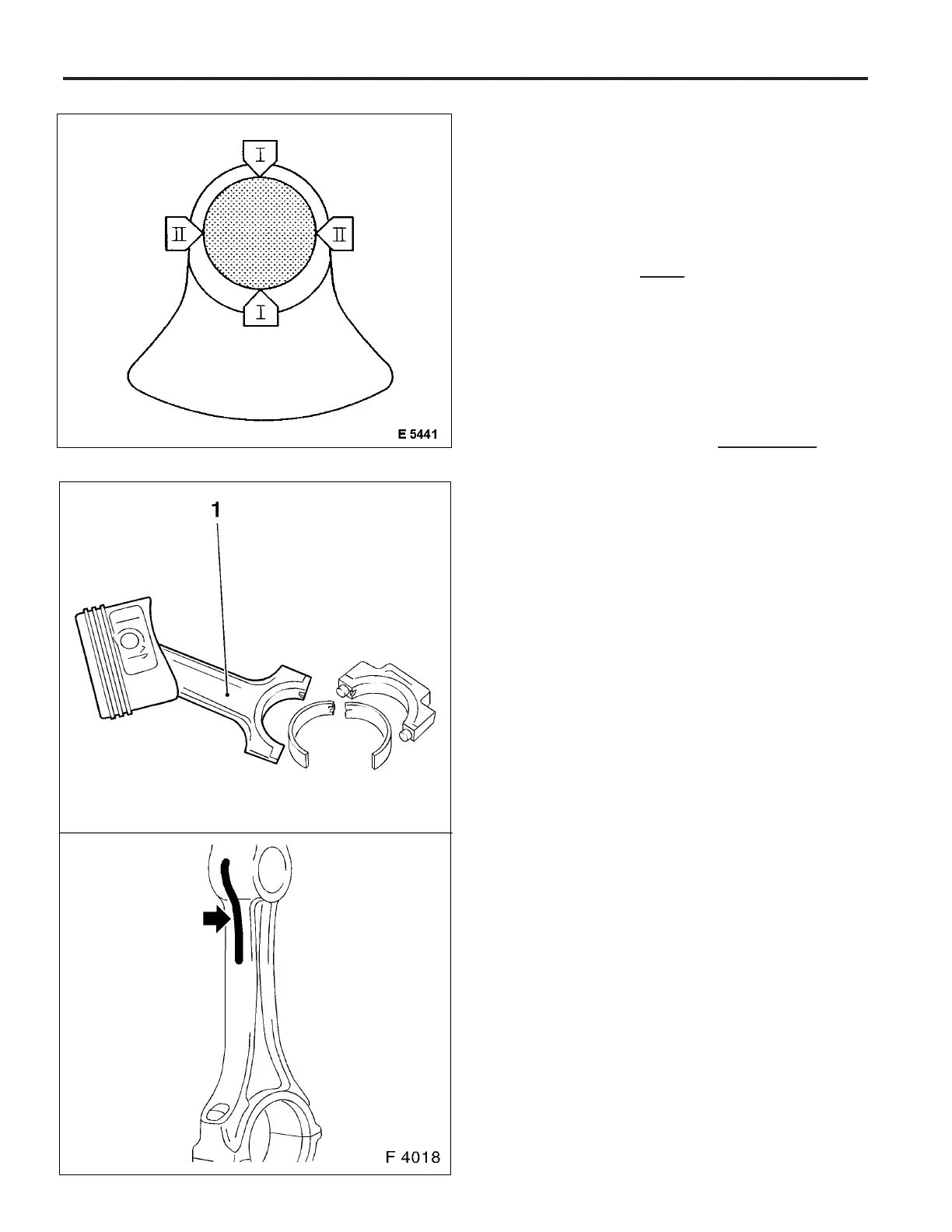

1. The con–rod bearing journal diameter is measured with a

micrometer at points I and II and then calculated.

Formula for calculating the average con–rod bearing jour-

nal diameter: I + II

2

Example:

I 42.729 mm

II + 42.725 mm

85.454 mm / 2 = 42.727 mm

The average con–rod bearing journal diameter is 42.727

mm.

The con–rod bearing clearance is calculated from the dif-

ference in diameter between the con–rod bearing bore and

the con–rod bearing journal.

Example:

Avg. con–rod bearing dia. 42.737 mm

Avg. con–rod bearing journal dia. - 42.727 mm

0.010 mm

Permissible con–rod bearing clearance: 0.019 to 0.071

mm.

Piston, Replace

Notice: Removal of the piston pin is not permitted. If the

piston, the piston pin or the con–rod is defective, all

above–mentioned parts must be replaced.

Removal Procedure

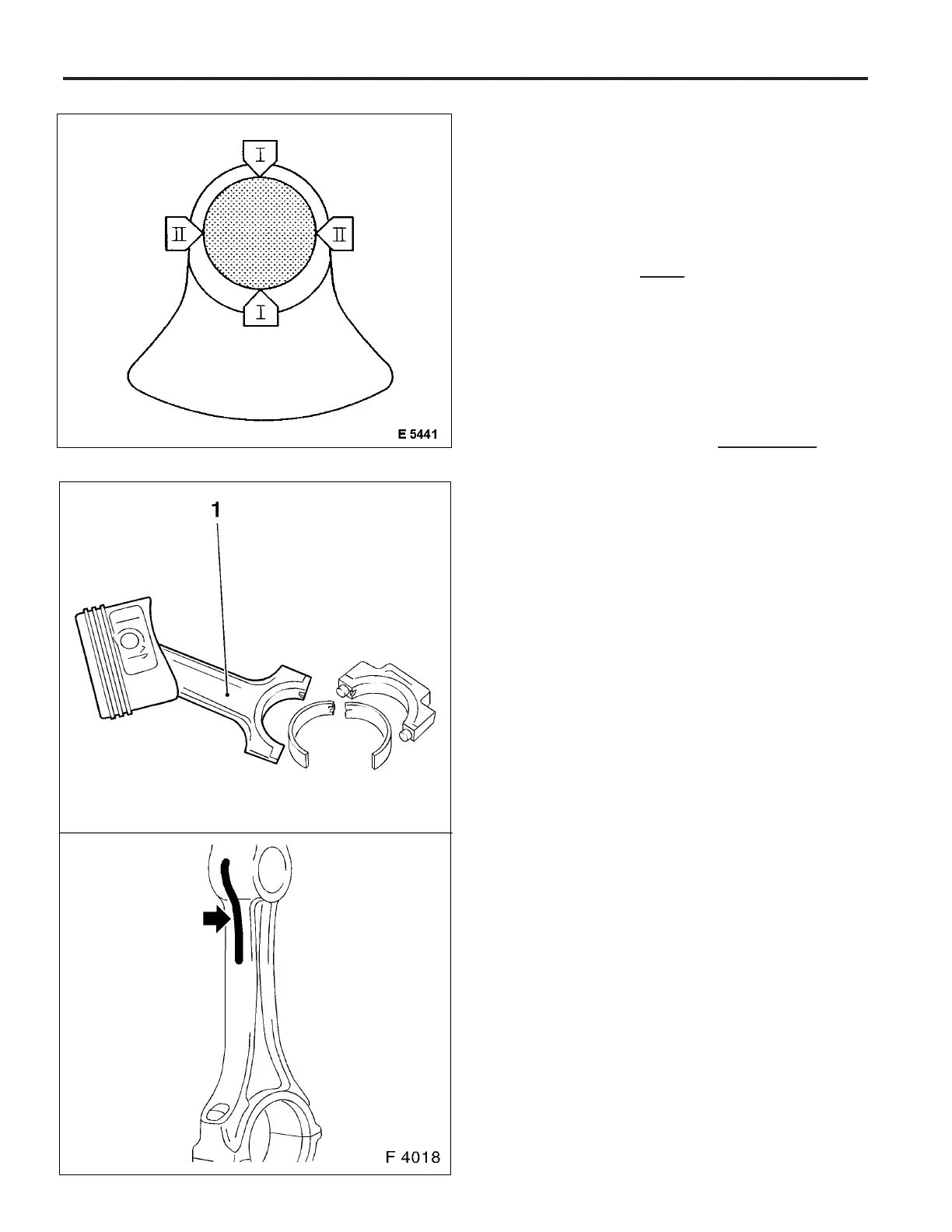

1. Remove piston with con–rod (1) – see operation Piston

with Con–rod, Remove and Install.

Installation Procedure

1. Coat con–rod eye and upper part of the con–rod shaft

with thermocolor pencil. The green coloring turns black

when the required assembly temperature is reached. The

colored mark (arrow) is not permitted to discolor over the

entire length, but only up to the start of the con–rod shaft.

Heat new con–rod at upper con–rod eye with heater plate.

Assembly temperature: 280 °C / 536 °F to max. 320 °C /

608 °F.

Loading...

Loading...