1-70 Engine Mechanical Industrial 1.6L

Crankshaft, Check

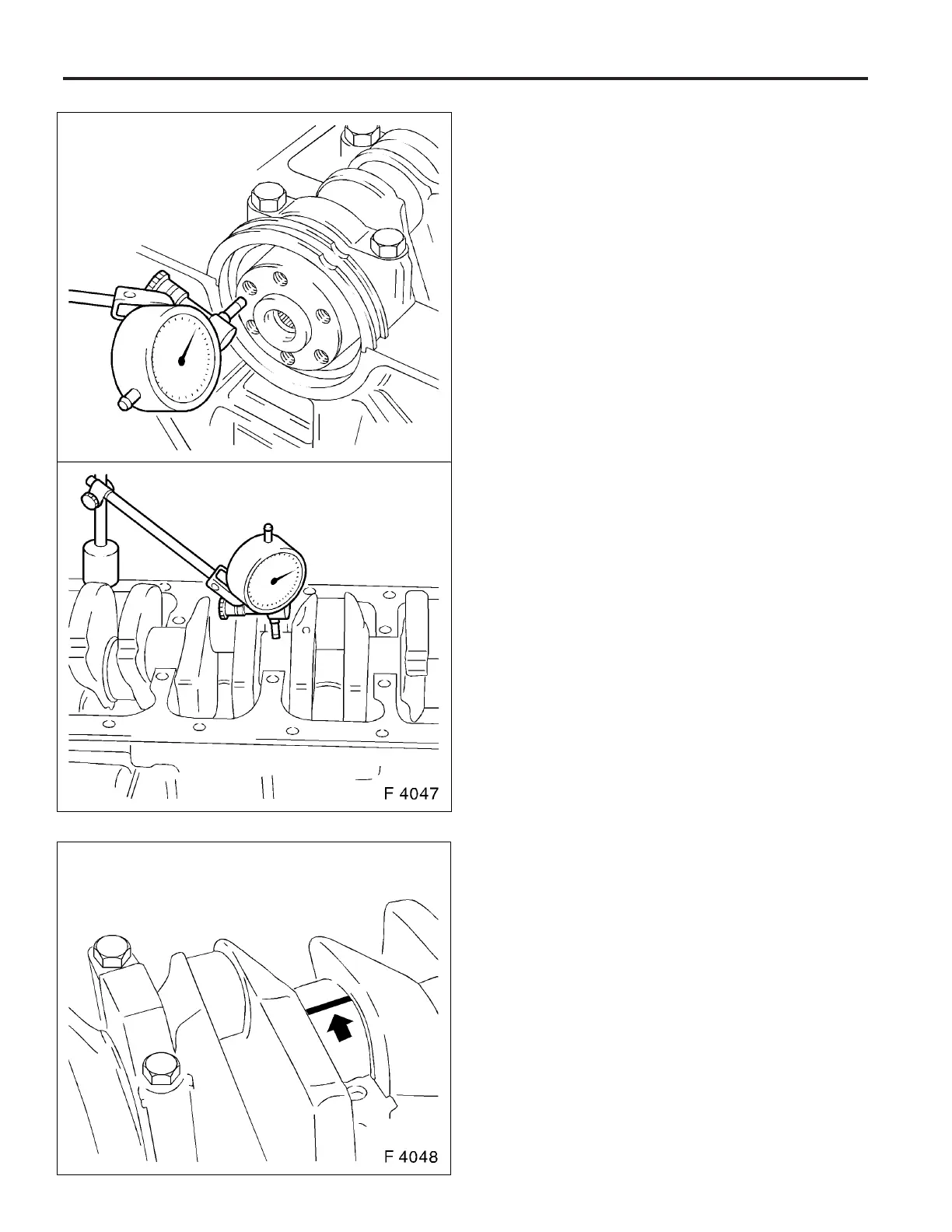

Crankshaft End Clearance, Check

Measure

1. Attach Dial Gauge MKM–571–B with dial gauge bracket

to one face of cylinder block and position probe of dial

gauge on crankshaft.

2. Slide crankshaft in longitudinal direction. Permissible

crankshaft longitudinal play: 0.100 to 0.202 mm.

Crankshaft Out–of–round, Check

Inspect

1. Remove crankshaft bearing cap.

2. Attach Dial Gauge MKM–571–B with dial gauge bracket

to cylinder block.

3. Apply probe of the Dial Gauge MKM–571–B to crank

shaft bearing journal.

4. Turn crankshaft uniformly. Max. perm. out–of–round: 0.03

mm.

5. Crankshaft bearing cap with new bolts to cylinder block.

Tighten

Tightening torque 50 Nm / 37 lb. ft. + 45° + 15°.

Crankshaft Bearing Play, Check (Determine

Bearing Play with Plastigage)

Inspect

1. Bearing play – crankshaft bearing cap removed.

Important: To prevent thread from tearing when removing

con–rod bearing cap, remove grease from con–rod journal

and lightly oil con–rod bearing shell. Do not turn

crankshaft.

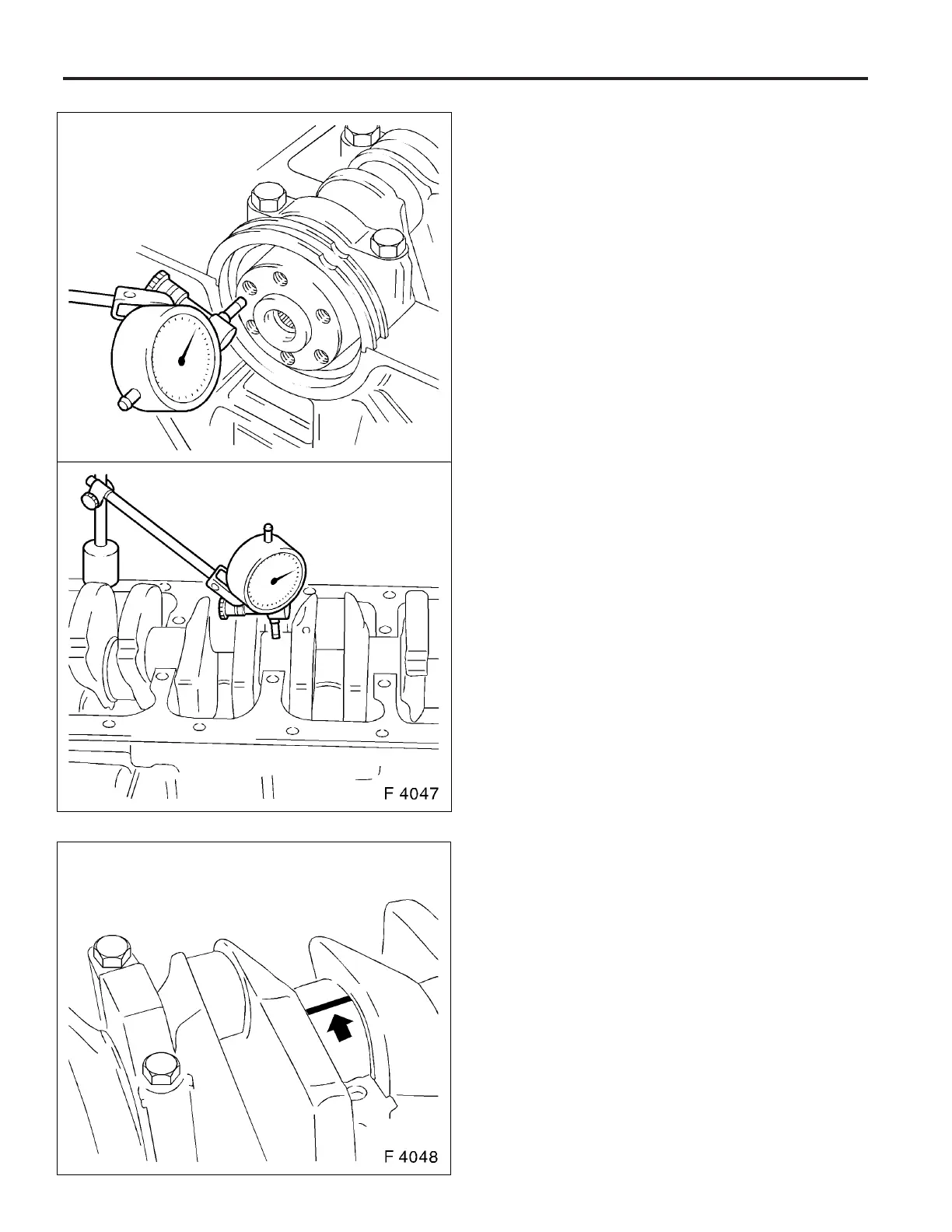

Measure

1. With ”Plastigage” (deformable plastic thread).

2. Cut thread to bearing width and lay axially between crank-

shaft journal and bearing shell (arrow). Install crankshaft

bearing cap with torque –

Tighten

Tightening torque 50 Nm / 37 lb. ft. + 45° + 15°.

Notice: The bolts can be reused for checking crankshaft

bearing clearance.

Loading...

Loading...