Industrial 1.6L Engine Mechanical 1-65

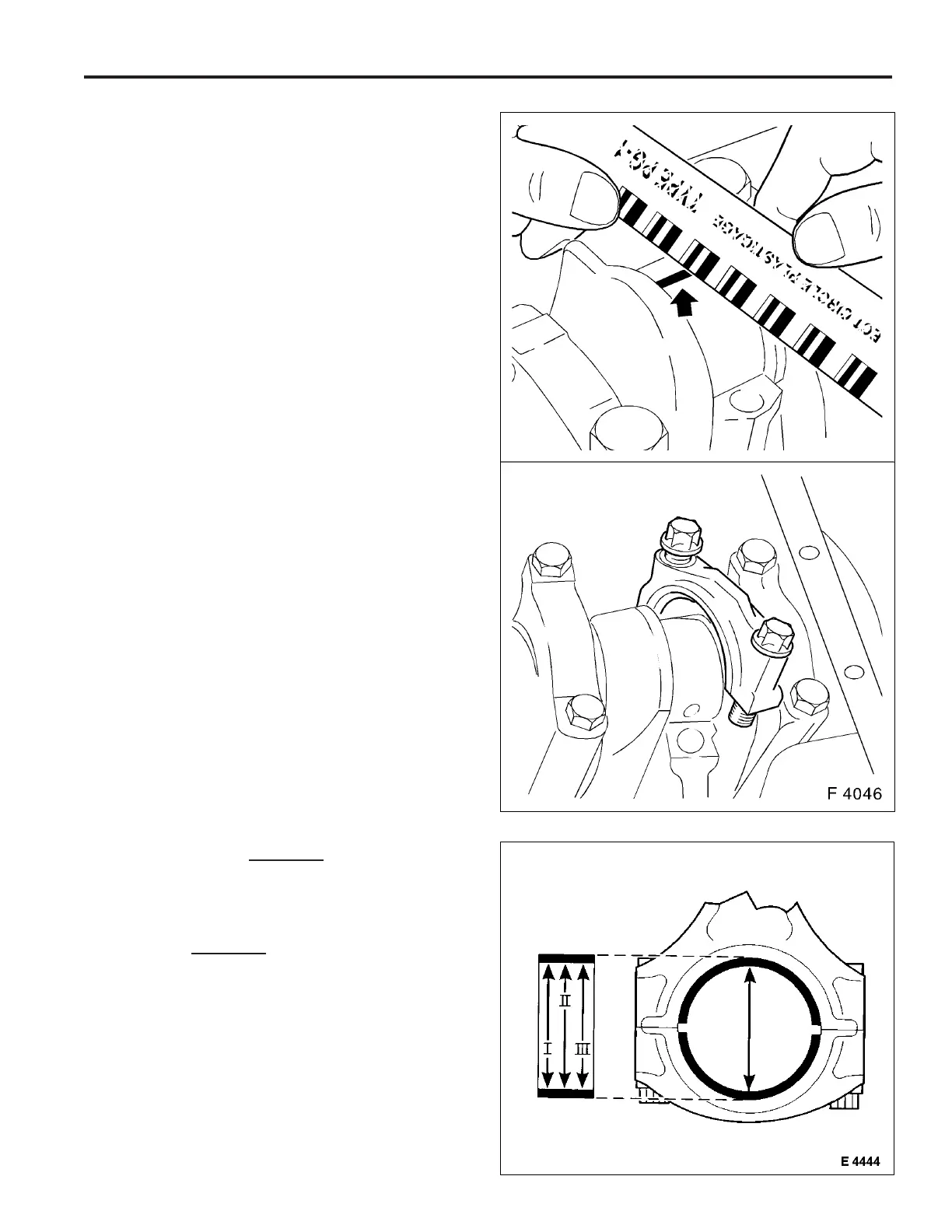

Measure

1. Remove con–rod bearing cap again. Compare width of

flattened plastic thread (arrow) with measuring scale.

Permissible con–rod bearing clearance: 0.019 to 0.071

mm.

Notice: When reading the value, do not confuse

millimeters and inches on the measuring scale.

Installation Procedure

1. Clean con–rod bearing journal and con–rod bearing shell

and lubricate lightly.

2. Con–rod bearing cap to con–rod – note installation posi-

tion of the con–rod bearing cap.

3. Attach con–rod bearing cap to con–rod with new bolts.

Tighten

Tightening torque 25 Nm / 18.5 lb. ft. + 30°.

Con–rod Bearing Clearance, Check

(Determine Bearing Clearance with

Micrometer and Inside Micrometer)

Notice: Con–rod and crankshaft are removed.

Installation Procedure

1. Con–rod bearing cap with con–rod bearing shell to con–

rod.

Tighten

Tightening torque 25 Nm / 18 lb. ft. + 30°.

The bolts can be reused for checking the con–rod bear-

ing clearance.

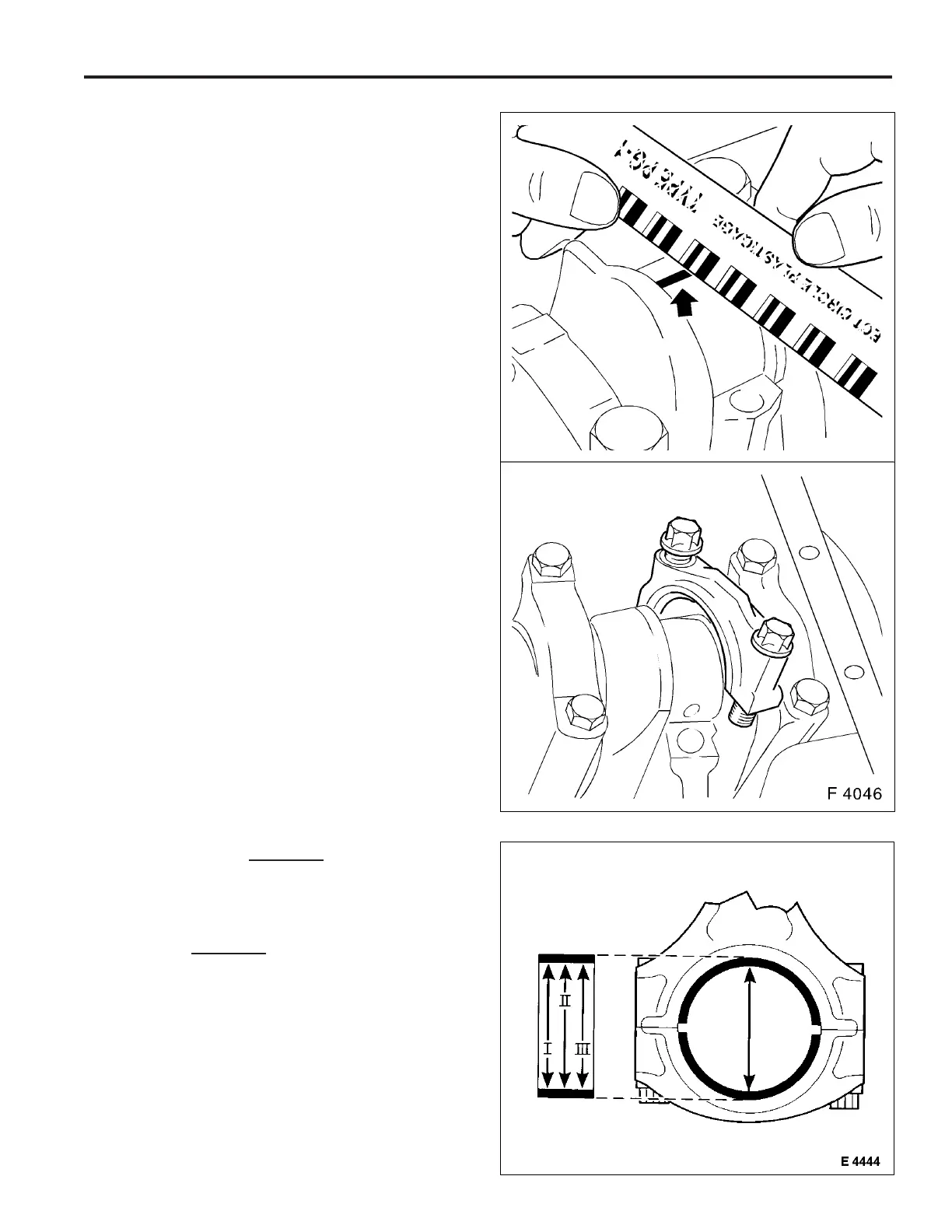

Formula for calculating the average con–rod bearing di-

ameter: I + II + III

3

Example:

I 42.738 mm

II 42.732 mm

III + 42.741 mm

128.211 mm / 3 = 42.737 mm

The average con–rod bearing diameter is 42.737 mm.

Loading...

Loading...