Industrial 1.6L Engine Mechanical 1-63

Con–rod Bearing, Replace

Removal Procedure

1. Remove oil pan – see operation Oil Pan, Remove and

Install.

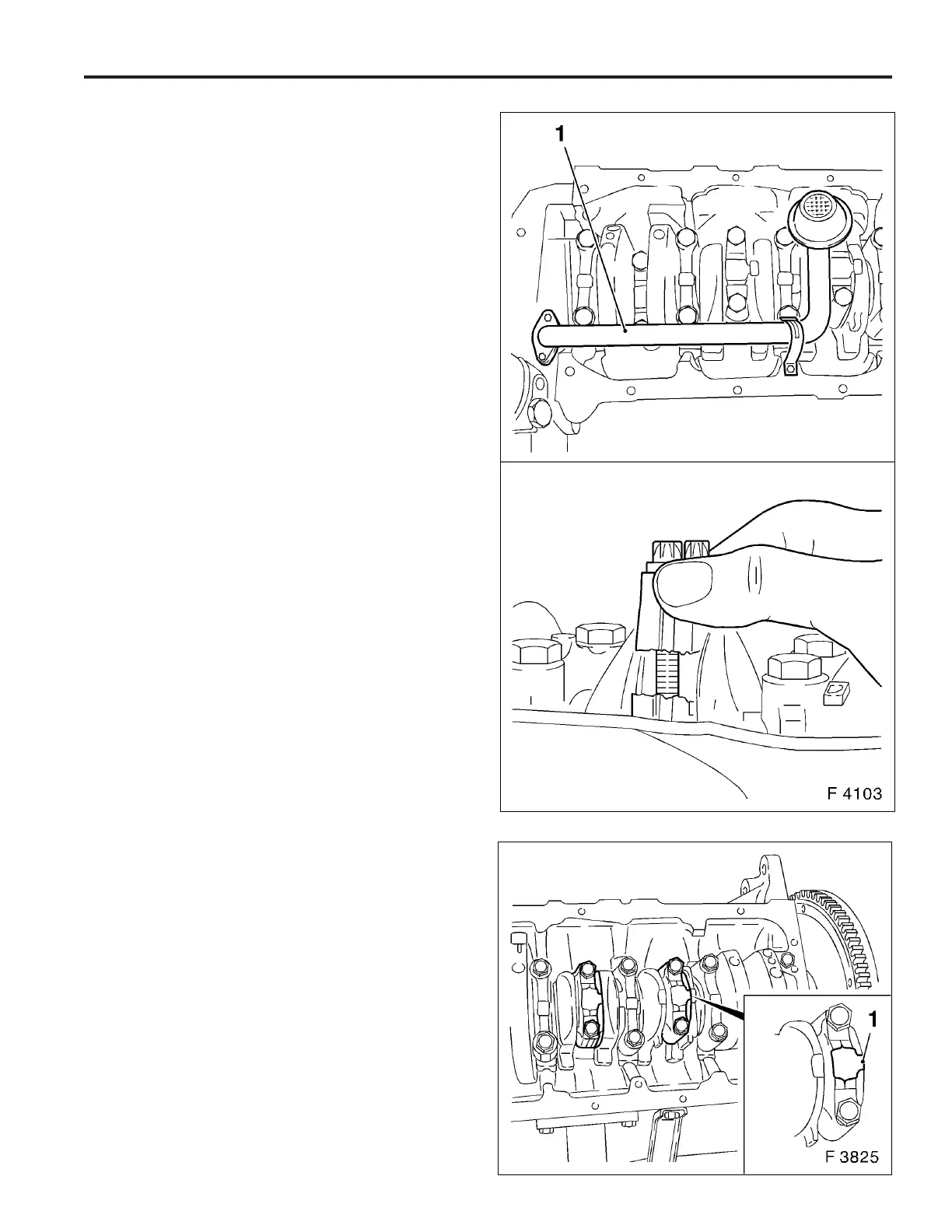

2. Remove oil intake tube (1) from oil pump and cylinder

block.

Important: Mark order of con–rod bearing caps.

3. Remove con–rod bearing cap from con–rod.

Important: The mating surfaces of the cod–rods and the

con–rod bearing caps form an individual fit and as a result

must not be damaged or replaced under any

circumstances. Do not lay con–rods and con–rod bearing

caps on mating surfaces in order to avoid damage. Press

con–rod bearing out of con–rod and con–rod bearing cap.

Clean

1. Con–rod bearing journals and con–rod bearing caps.

Installation Procedure

1. Insert new con–rod bearing shells with engine oil.

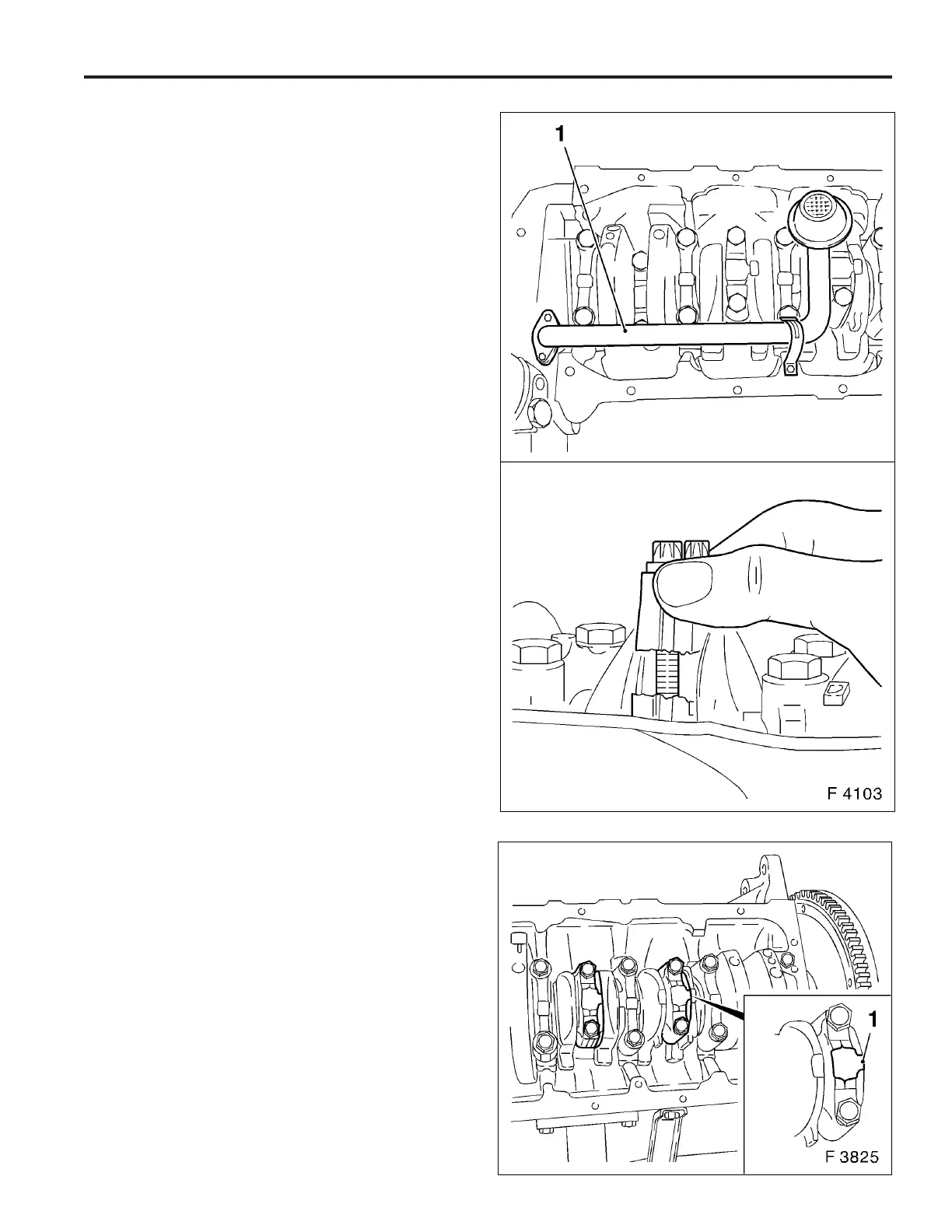

Important: Note sequence of con–rod bearing caps. Con–

rod bearing caps – bead (1) of con–rod bearing caps points

to flywheel side.

2. Attach con–rod bearing cap to con–rod with new bolts.

Tighten

Tightening torque 25 Nm / 18.5 lb. ft. + 30°.

3. Attach oil intake manifold to oil pump with new seal ring.

Tighten

Tightening torque 8 Nm / 6 lb. ft.

4. Attach oil intake manifold to cylinder block.

Tighten

Tightening torque 8 Nm / 6 lb. ft.

5. Apply a bead of adhesive sealing compound (black) to

joints of oil pump and rear crankshaft bearing cap.

6. Install oil pan – see operation Oil Pan, Remove and

Install.

Important: Clean up or recut threads with proper die before

reassembly and coat threads of new bolts with screw lock-

ing compound (red). The installation time including the torque

check is max. 10 min.

Loading...

Loading...