88 Electrical installation

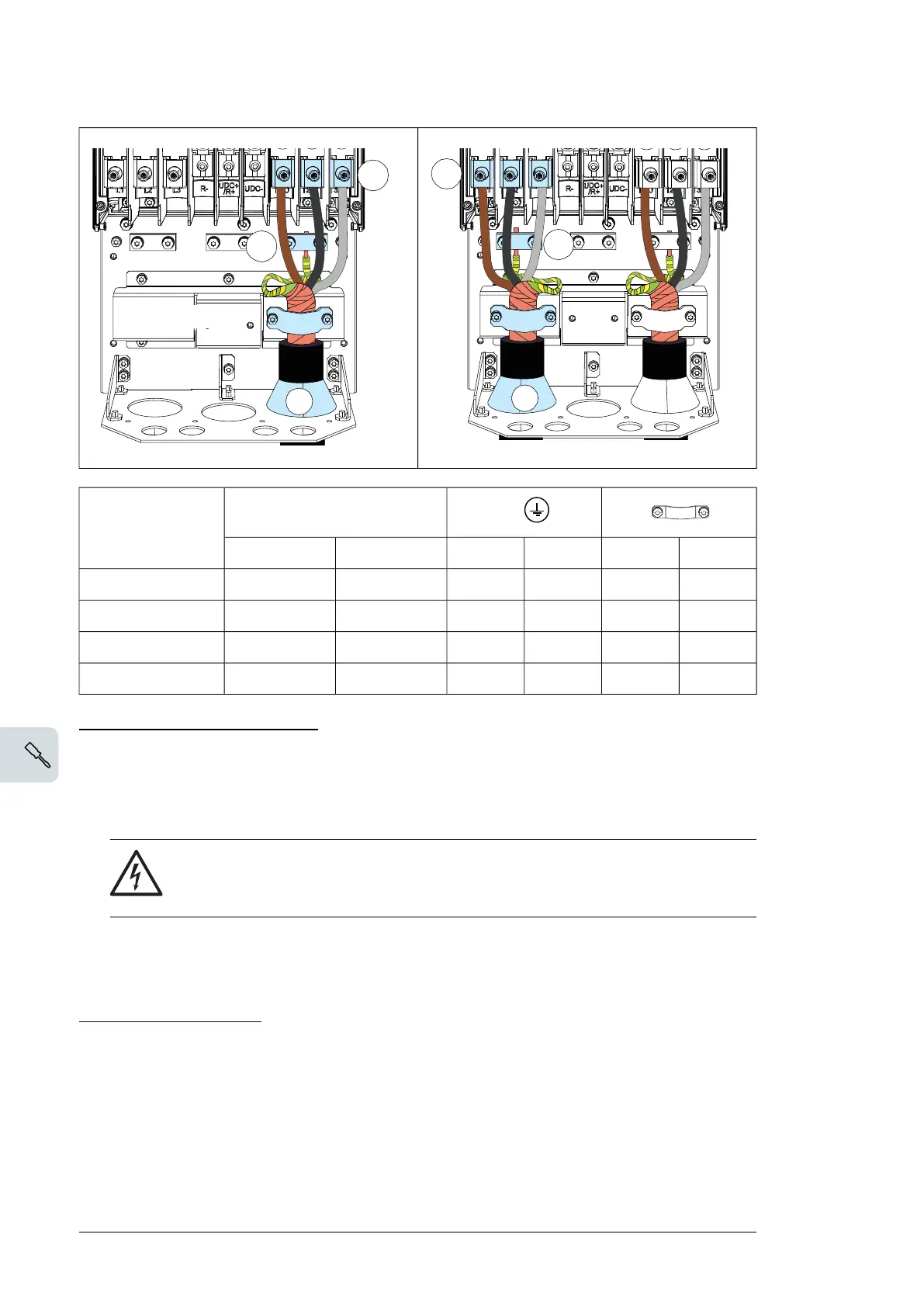

Notes for frame R8

• If you connect only one conductor to the connector, we recommend that you put it

under the upper pressure plate.

• The connectors are detachable but we do not recommend that you detach them.

If you do, detach and reinstall the connectors as follows.

Input power cable

10. Connect the input power cable as in step 9. Use terminals L1, L2 and L3.

Terminals T1/U, T2/V and T3/W

• Remove the nut that attaches the connector to its busbar.

• Put the conductor under the connector pressure plate and pre-tighten the

conductor.

• Put the connector back to its busbar. Start the nut, and turn it at least two

rotations by hand.

WARNING! Before using tools, make sure that the nut/screw is not cross-

threading. Cross-threading will damage the drive and cause danger.

• Tighten the nut to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m

(52 lbf·ft) for frame R8.

8

M5×25/35

Frame size L1, L2, L3, T1/U, T2/V, T3/W PE,

N·m lbf·ft N·m N·m N·m lbf·ft

R6 30 22.1 9.8 7.2

R7 40 29.5 9.8 7.2

R8 40 29.5 9.8 7.2

8

9a

10a

10b9b

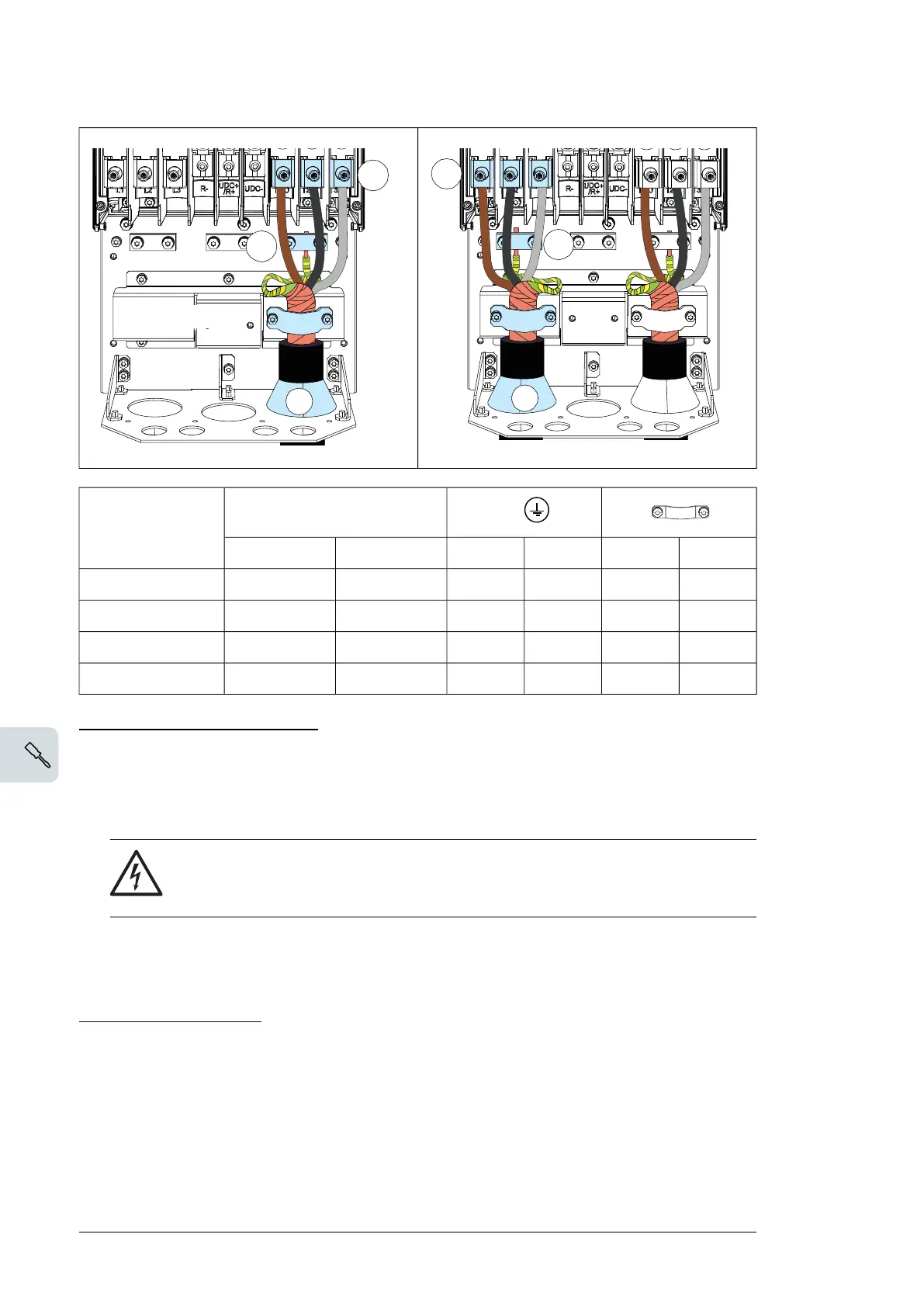

88 Electrical installation

Notes for frame R8

• If you connect only one conductor to the connector, we recommend that you put it

under the upper pressure plate.

• The connectors are detachable but we do not recommend that you detach them.

If you do, detach and reinstall the connectors as follows.

Input power cable

10. Connect the input power cable as in step 9. Use terminals L1, L2 and L3.

Terminals T1/U, T2/V and T3/W

• Remove the nut that attaches the connector to its busbar.

• Put the conductor under the connector pressure plate and pre-tighten the

conductor.

• Put the connector back to its busbar. Start the nut, and turn it at least two

rotations by hand.

WARNING! Before using tools, make sure that the nut/screw is not cross-

threading. Cross-threading will damage the drive and cause danger.

• Tighten the nut to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m

(52 lbf·ft) for frame R8.

8

M5×25/35

Frame size L1, L2, L3, T1/U, T2/V, T3/W PE,

N·m lbf·ft N·m N·m N·m lbf·ft

R6 30 22.1 9.8 7.2

R7 40 29.5 9.8 7.2

R8 40 29.5 9.8 7.2

8

9a

10a

10b9b

PE

L1, L2, L3, T1/U, T2/V, T3/WFrame size

lbf·ftN·mlbf·ftN·mlbf·ftN·m

0.91.21.62.24.15.6R5

0.91.27.29.822.130R6

0.91.27.29.829.540R7

0.91.27.29.829.540R8

Terminals T1/U, T2/V and T3/W

• Remove the nut attached to the connector and its busbar.

• Put the conductor under the connector pressure plate and pre-tighten the conductor.

• Put the connector back to its busbar. Start the nut, and turn it by hand to at least two

rotations.

WARNING! WARNING!

Before using tools, make sure that the nut/screw is not cross-threaded.

Cross-threading damages the drive and causes danger.

• Tighten the nut to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m (52 lbf·ft) for

frame R8.

Terminals L1, L2 and L3

• Remove the combi screw attached to the connector and to its terminal post, and pull

the connector off.

• Put the conductor under the connector pressure plate and pre-tighten the conductor.

• Put the connector back onto the terminal post. Start the combi screw, and turn it by

hand to at least two rotations.

82 Electrical installation

Loading...

Loading...