WARNING! WARNING!

Before using tools, make sure that the nut/screw is not cross-threaded.

Cross-threading can damage the drive and cause danger.

• Tighten the combi screw to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m (52 lbf·ft) for

frame R8.

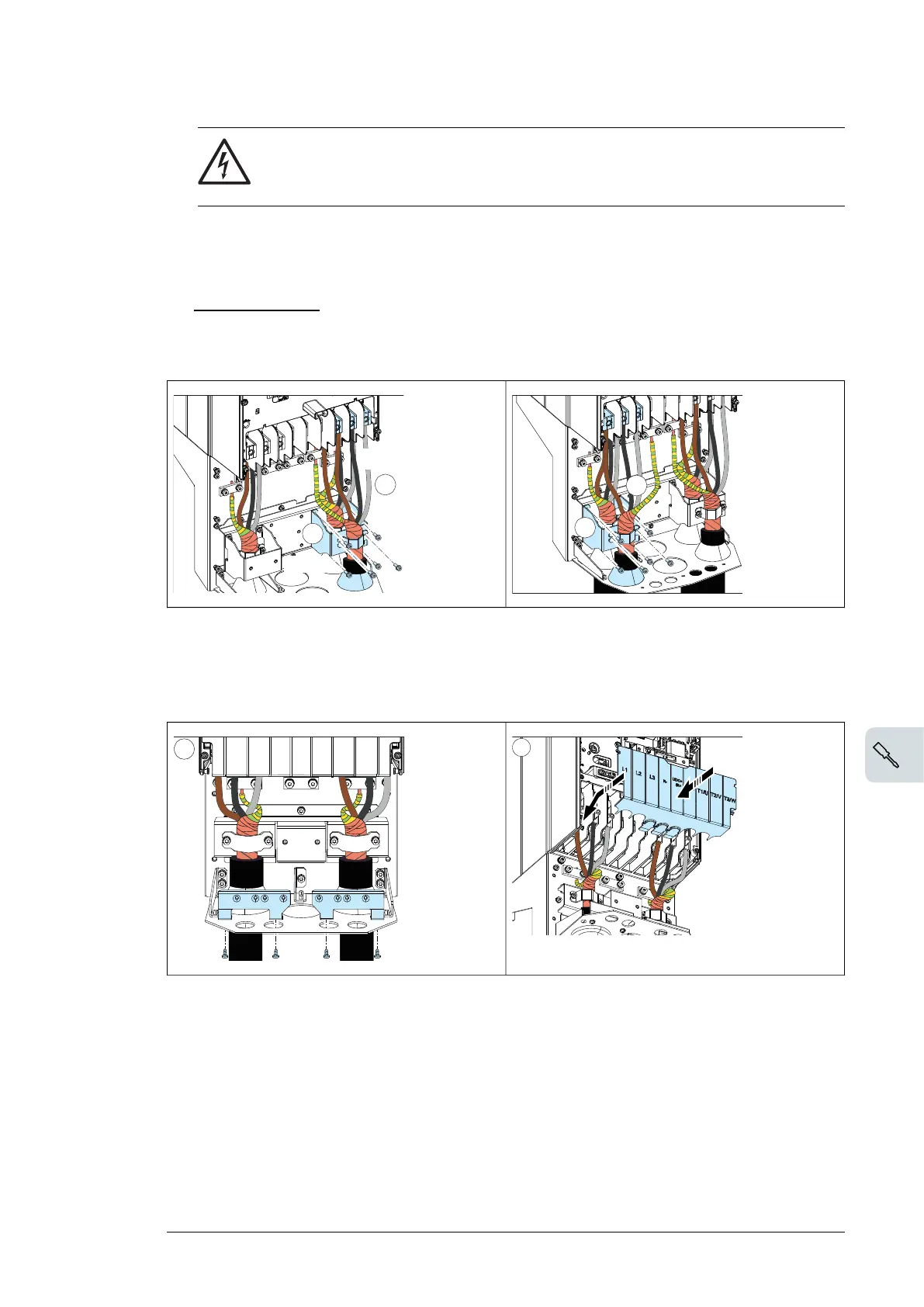

11. Frames R8 only: If you install parallel cables, install the second grounding shelf for the

parallel power cables (11a). Repeat steps 6...11 (11b).

Frame R8:

Electrical installation 89

Terminals L1, L2 and L3

• Remove the combi screw that attaches the connector to its terminal post, and

pull the connector off.

• Put the conductor under the connector pressure plate and pre-tighten the

conductor.

• Put the connector back onto the terminal post. Start the combi screw, and turn

it at least two rotations by hand.

WARNING! Before using tools, make sure that the nut/screw is not cross-

threading. Cross-threading will damage the drive and cause danger.

• Tighten the combi screw to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m

(52 lbf·ft) for frame R8.

11. Frames R8

If you install parallel cables, install the second grounding shelf for the

parallel power cables (11a). Repeat steps 6...11 (11b).

12. Install the grounding shelf of the control cables.

M5×25

M5×12

11a

11b

11a

11b

R8 R8

Electrical installation 89

Terminals L1, L2 and L3

• Remove the combi screw that attaches the connector to its terminal post, and

pull the connector off.

• Put the conductor under the connector pressure plate and pre-tighten the

conductor.

• Put the connector back onto the terminal post. Start the combi screw, and turn

it at least two rotations by hand.

WARNING! Before using tools, make sure that the nut/screw is not cross-

threading. Cross-threading will damage the drive and cause danger.

• Tighten the combi screw to a torque of 30 N·m (22 lbf·ft).

• Tighten the conductor(s) to 40 N·m (30 lbf·ft) for frame R8 or to 70 N·m

(52 lbf·ft) for frame R8.

11. Frames R8

If you install parallel cables, install the second grounding shelf for the

parallel power cables (11a). Repeat steps 6...11 (11b).

12. Install the grounding shelf of the control cables.

M5×25

M5×12

11a

11b

11a

11b

R8 R8

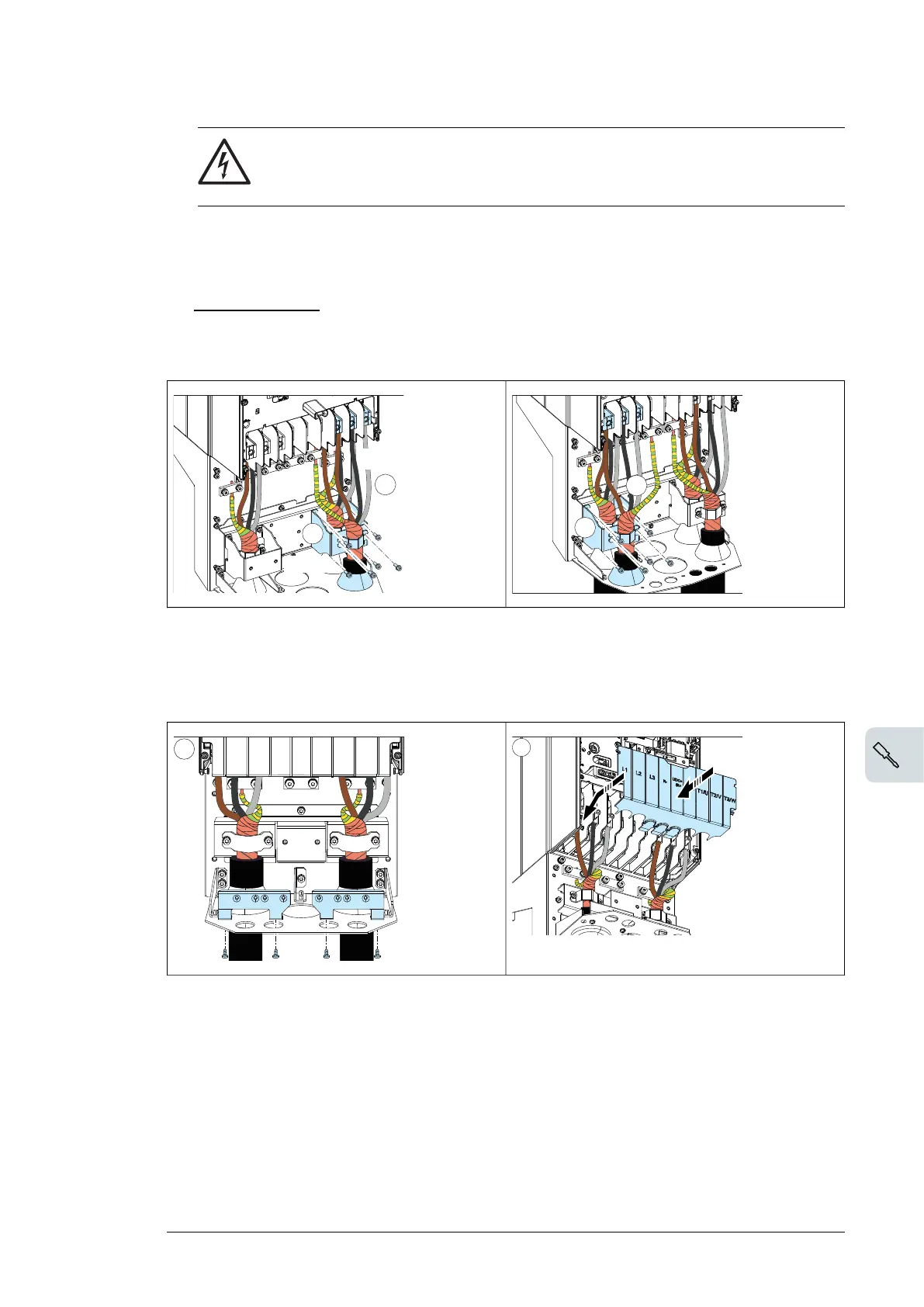

12. Install the grounding shelf of the control cables.

13. Reinstall the shroud on the power terminals.

14. Secure the cables outside the unit mechanically.

90 Electrical installation

13. Reinstall the shroud on the power terminals.

14. Secure the cables outside the unit mechanically.

15. Ground the motor cable shield at the motor end. For minimum radio frequency

interference, ground the motor cable shield 360 degrees at the lead-through of

the motor terminal box.

DC connectio n

The UDC+ and UDC- terminals (as standard in frames R4…R8) are for using external

brake chopper units.

1312

15

90 Electrical installation

13. Reinstall the shroud on the power terminals.

14. Secure the cables outside the unit mechanically.

15. Ground the motor cable shield at the motor end. For minimum radio frequency

interference, ground the motor cable shield 360 degrees at the lead-through of

the motor terminal box.

DC connection

The UDC+ and UDC- terminals (as standard in frames R4…R8) are for using external

brake chopper units.

1312

15

Electrical installation 83

Loading...

Loading...