Agilent 5110/5100 ICP-OES Service Manual Agilent Restricted 157

5 Troubleshooting

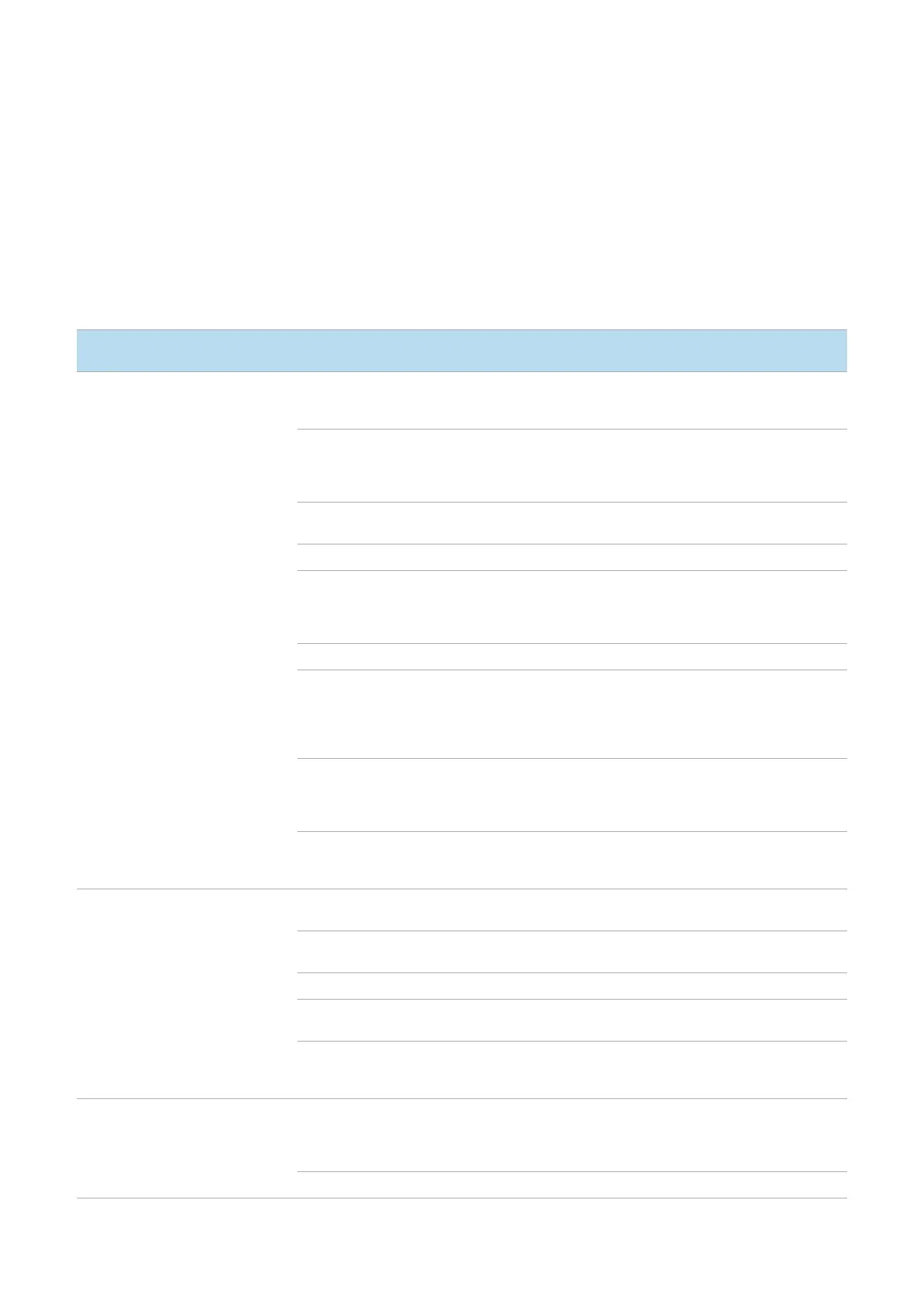

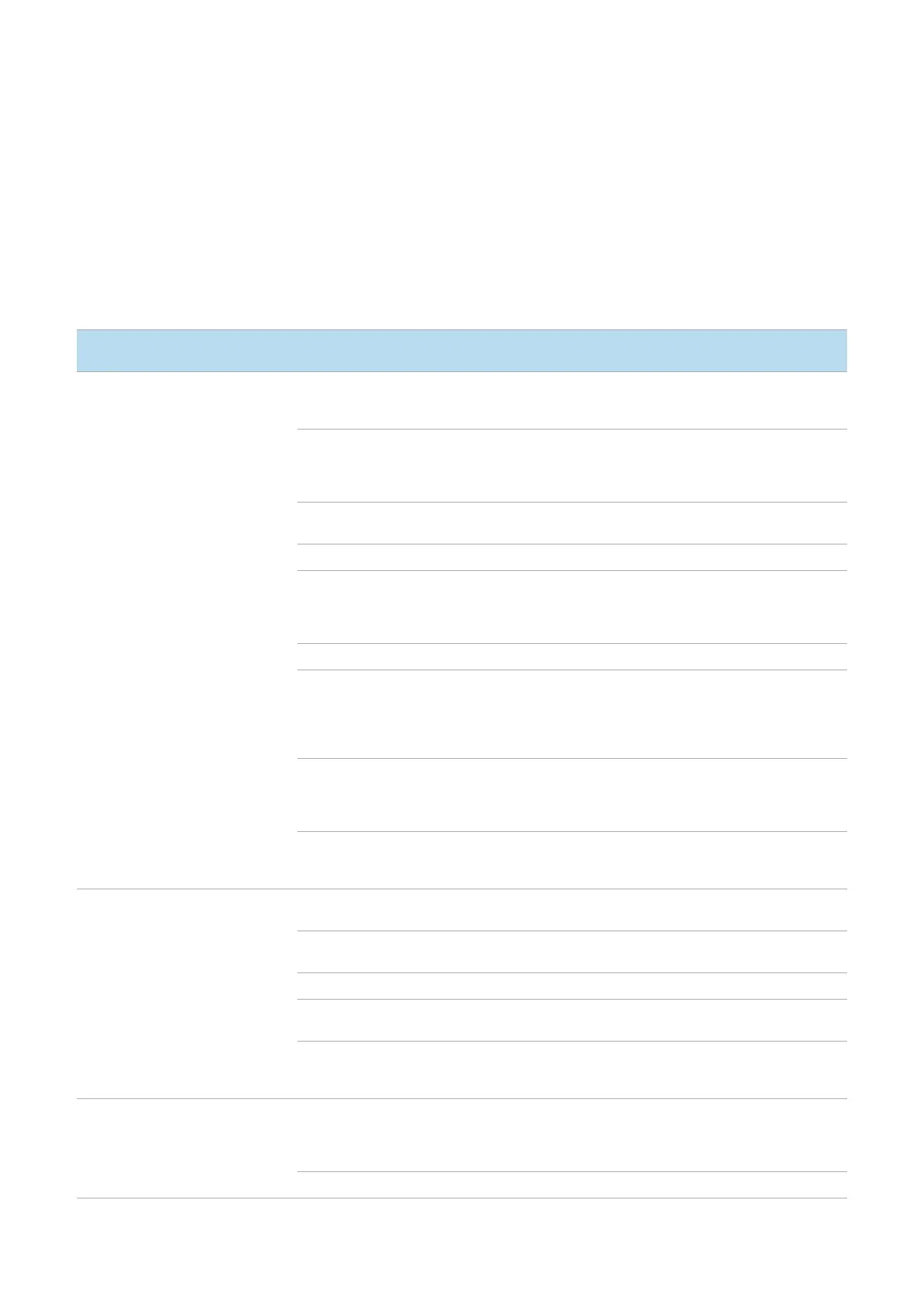

Sensitivity Failure - Analysis Table

Failing Sensitivity test will verify a problem exists. Check which Wavelengths are failing and by

how much. Compare to installation or past IQ numbers. The table below will give some direction

as to failure mode and possible cause.

Sensitivity Failure - Analysis Table

Failure Mode (Intensity) Possible cause Possible cause (Next level)

Red indicates a probable service call required

All Wavelengths very low Sample Introduction major blockage Nebulizer Blocked

Tubing kinked, blocked, dirty (including accessories)

Torch injector blocked

Leaking fitting Nebulizer

Pump tubing

Sampler

Bubbles in tubing

Sample delivery Pump Tube Tension

Pump Tube stretched

Standard Concentration Standard Preparation

Optimization of parameters Nebulizer Flow

Viewing height (Radial)

Plasma Power

Pump Speed

Wavelengths off peak Instrument Calibration

Dark current values high Detector Calibration

Light Leak

Shutter problem

Optical Alignment

Camera Fault

Argon ratio incorrect Instrument Warm up

Polychromator temperature control

Pre Optics alignment

Polychromator alignment

Optical Alignment Preoptics

Polychromator

Camera Fault

Some Wavelengths failing Random peaks missing or low due to

moisture forming on Detector Lens

Moisture in Optics Purge lines. Refer to “Contaminated purge

gas” section in this Chapter

Contaminated Blank Sample preparation

Housekeeping

Sample Matrix Interference from EIE’s

Wavelengths off peak Instrument warm up

Instrument Calibration

Dark current values high Detector Calibration

Shutter problem

Camera Fault

Short Wavelengths Failing Air present in optics (Lack of Purging) Optics Purge

Boost Purge

Cone Purge

Snout Purge

Window Contamination Axial/Radial Windows

Loading...

Loading...