Agilent 5110/5100 ICP-OES Service Manual Agilent Restricted 47

3 General Information

Spraychambers

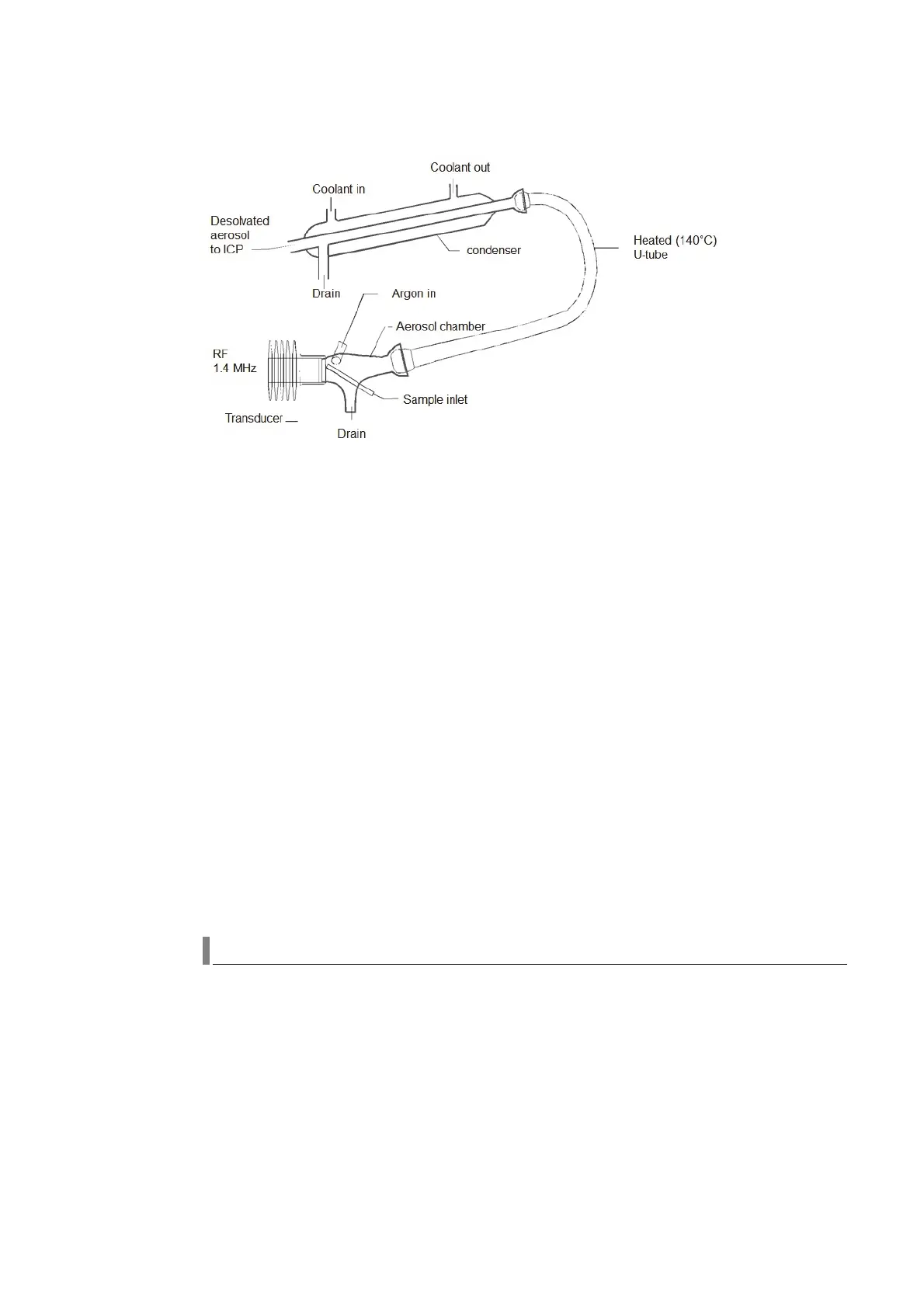

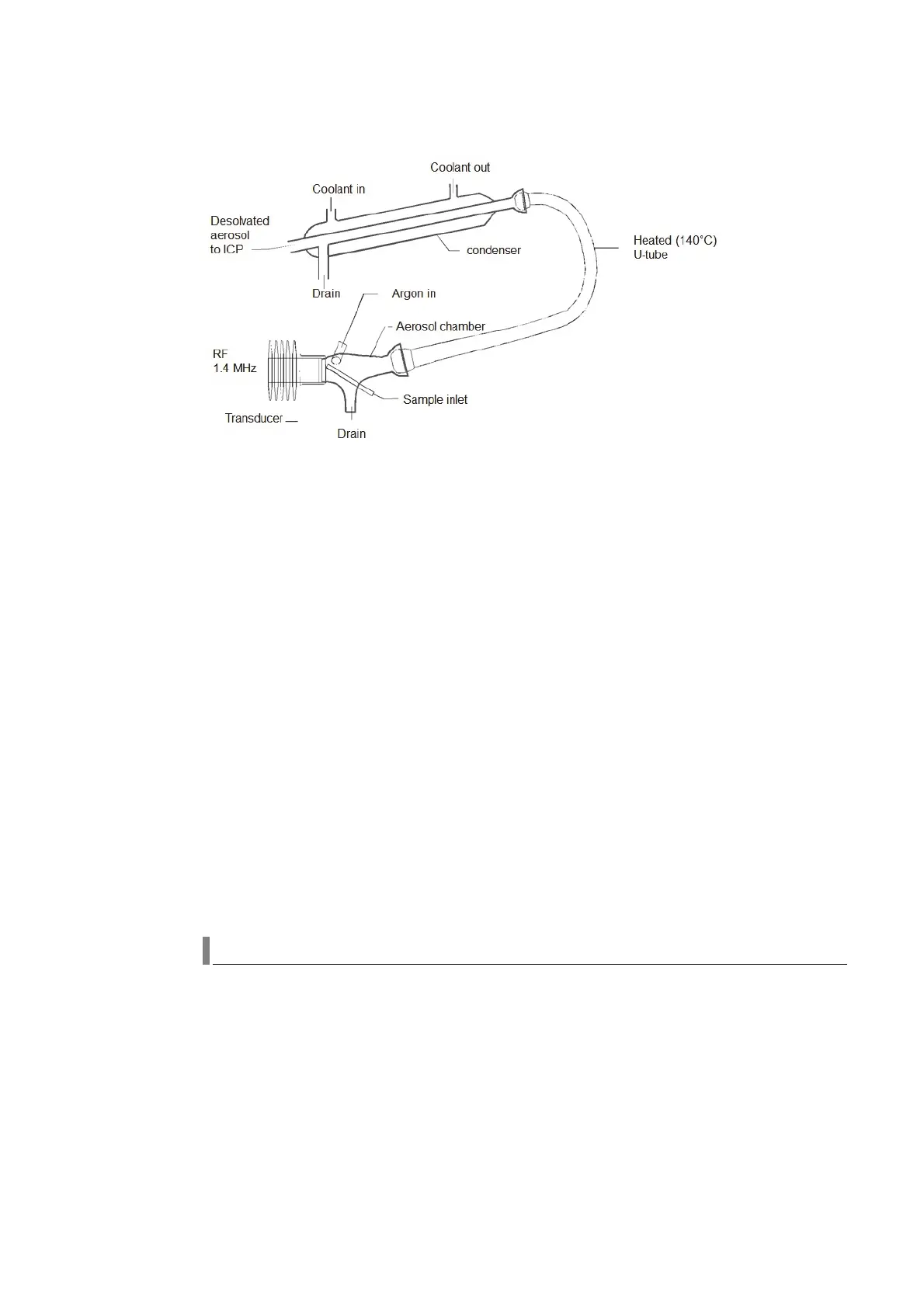

Figure 6. Ultrasonic nebulizer

The sample flows over a glass plate fixed to the transducer where ultrasonic vibrations cause

the aerosol to form. The carrier gas sweeps the sample aerosol into a desolvator and the dried

sample is then introduced into the plasma.

Spraychambers

The combined carrier gas and sample aerosol generated by the nebulizer are introduced into the

spraychamber.

The aerosol must be injected into the plasma at a uniform rate without causing plasma

destabilisation. In addition to this, the aerosol that is injected into the torch must also contain a

sufficient number of small droplets that are reproducible and representative of the sample. A

spraychamber is used to remove the larger droplets from the aerosol while providing a uniform

flow of aerosol to the torch. The spraychamber provides an interface to pass the aerosol to the

torch. The design transports a fine spray to the torch, while larger droplets coalesce, fall to the

bottom and are removed through the spraychamber drain by the pump and pump tubing.

Typical spraychambers used with the Agilent 5110 ICP-OES instruments include:

• Glass single-pass cyclone (Cyclonic)

• Glass double-pass cyclone (Cyclonic)

Double-pass glass cyclonic (Twister)

The Twister cyclonic Spraychamber features a central transfer tube which is more efficient in

removing larger aerosol droplets compared to the single-pass glass cyclonic spraychamber.

This reduces solvent load in the plasma making it better suited to more difficult sample types,

such as those containing higher dissolved solids (>5%) and low volatility organic solvents.

• Material: Borosilicate glass

• Volume: 50ml

• Physical reproducibility: ~1%

• Low RSD’s - highly accurate construction. Application uptake range 0.2 to 3.0ml/min

Loading...

Loading...