Pset STwrench User Guide

100 (326) 9836 4134 01 Edition 2.9

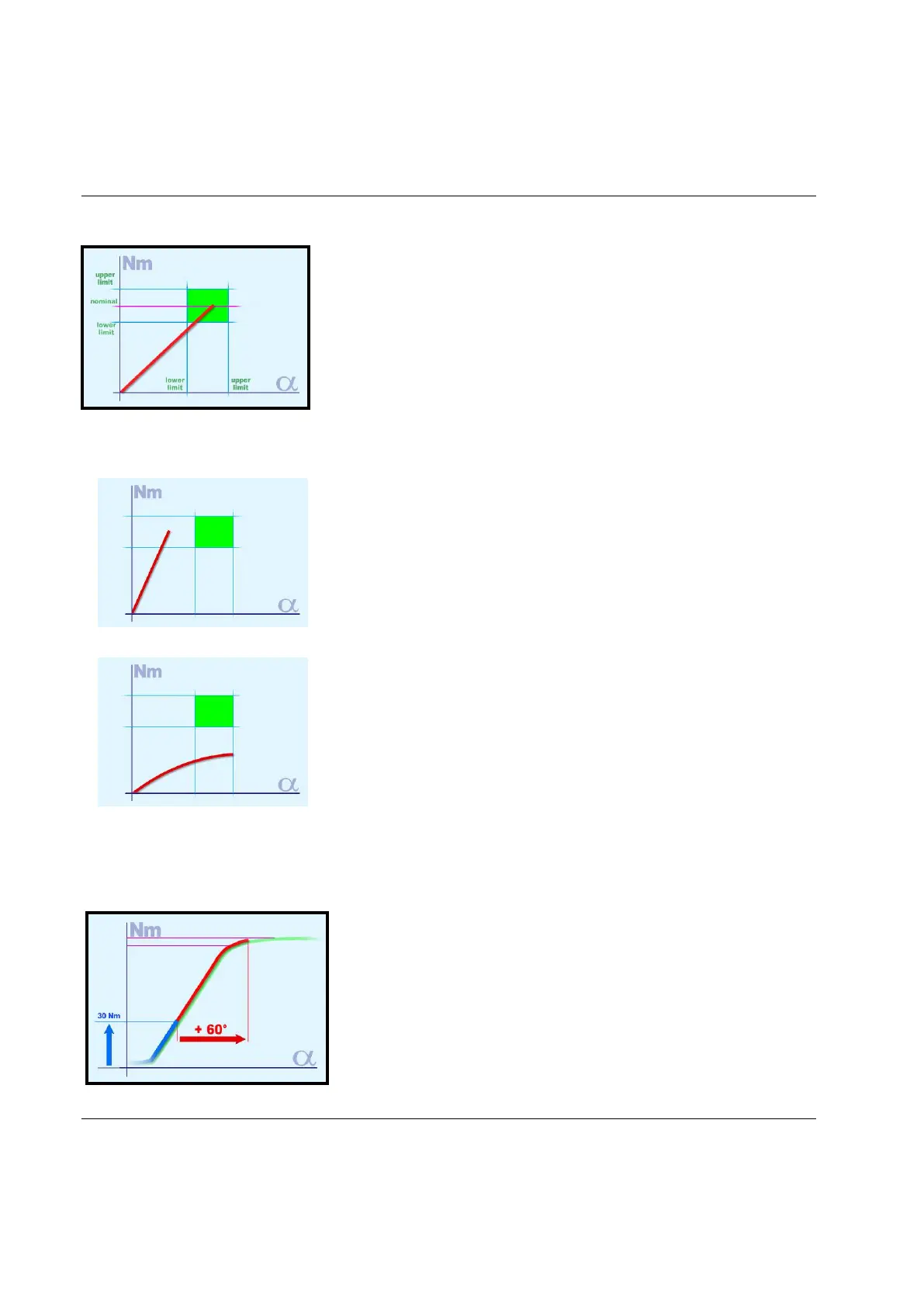

This is a more accurate way to tighten, as we use additional

information (angle) during the tightening process.

You can detect possible problems on the joint using this method:

Tor

que is correct, but angle is too short:

• Misalignment problem

• The hole is not completely threaded (or it is not deep enough)

• The bolt is stopped by oil in a dead hole

• There is dirt in the threads

• The threads are damaged

• The screw is already tightened

Angle is correct, but torque is too low:

• The thread may be stripped out

• The screw is too soft (tightened over yield)

• Unexpected low µ (friction coefficient)

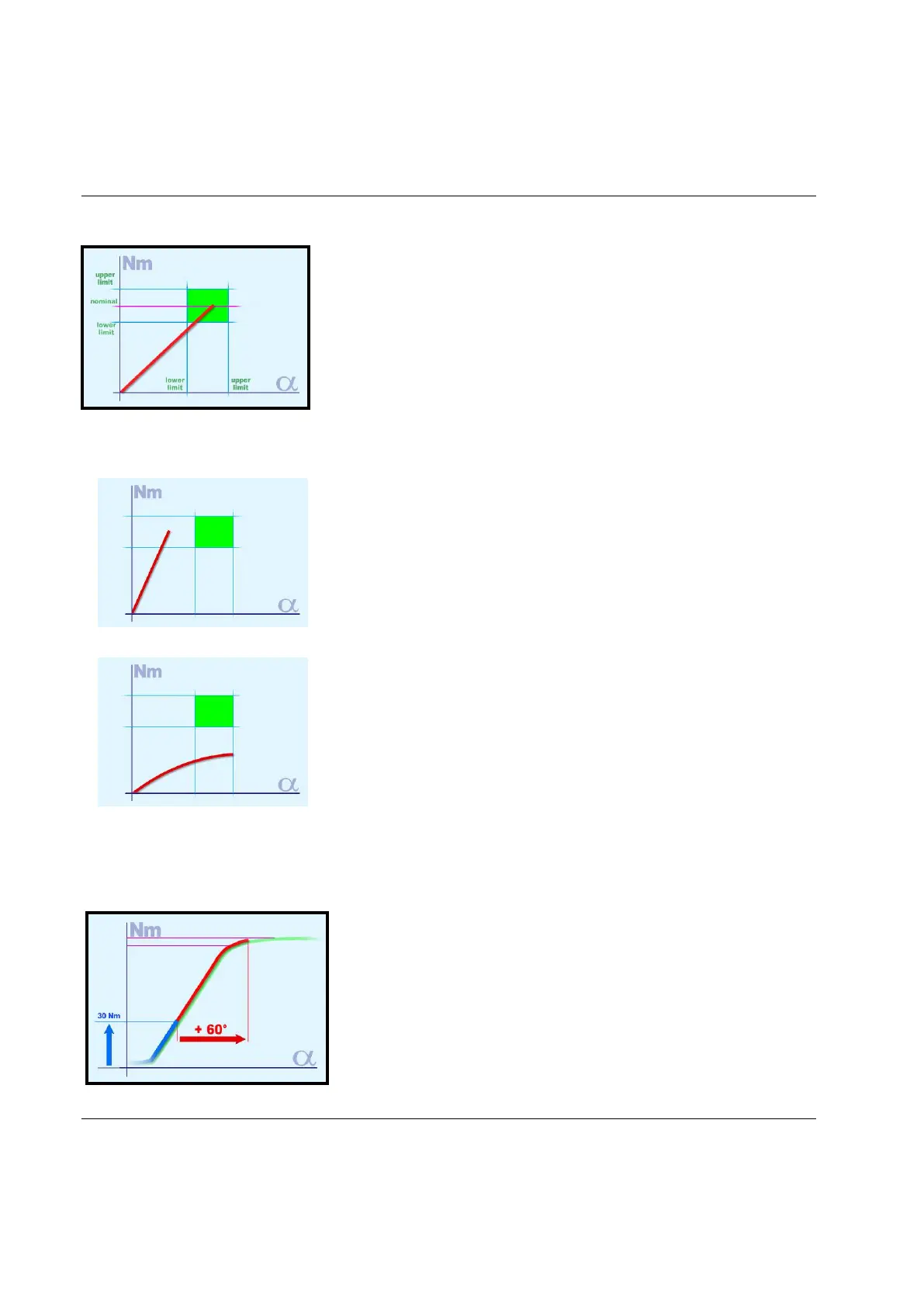

3. Tightening with torque and additional angle rotation (torque + angle)

The bolt is first tightened to a certain torque and then it is further

tightened to a specific angle.

Loading...

Loading...