STwrench Settings STwrench User Guide

184 (326) 9836 4134 01 Edition 2.9

10.3.2.3 Torque and Angle correction coefficients

Two coefficients to correct the torque and angle reading can be stored on the end-fitting tool. These

coefficients are used to correct the torque and angle measure when an extension is used on the STwrench.

The torque correction coefficient is used also to compensate the torque measurement when a torque

multiplier is used on the STwrench.

WARNING: Starting from firmware version 3.1, the Torque Correction Coefficient is given to

two decimal places. The end-fitting tools programmed with the STwrench using firmware 3.1x

or later cannot be used on STwrenches with firmware 3.0x or before (however, they will work if

re-programmed with firmware version 3.0x or before).

NOTE: These coefficients are not considered in the Free Mode.

Neither are they considered if the tool recognition function on the STwrench is disabled.

When using an extension, the black end-fitting tool should be welded to the extension in

order to maintain the automatic tool recognition and correction coefficients utilization.

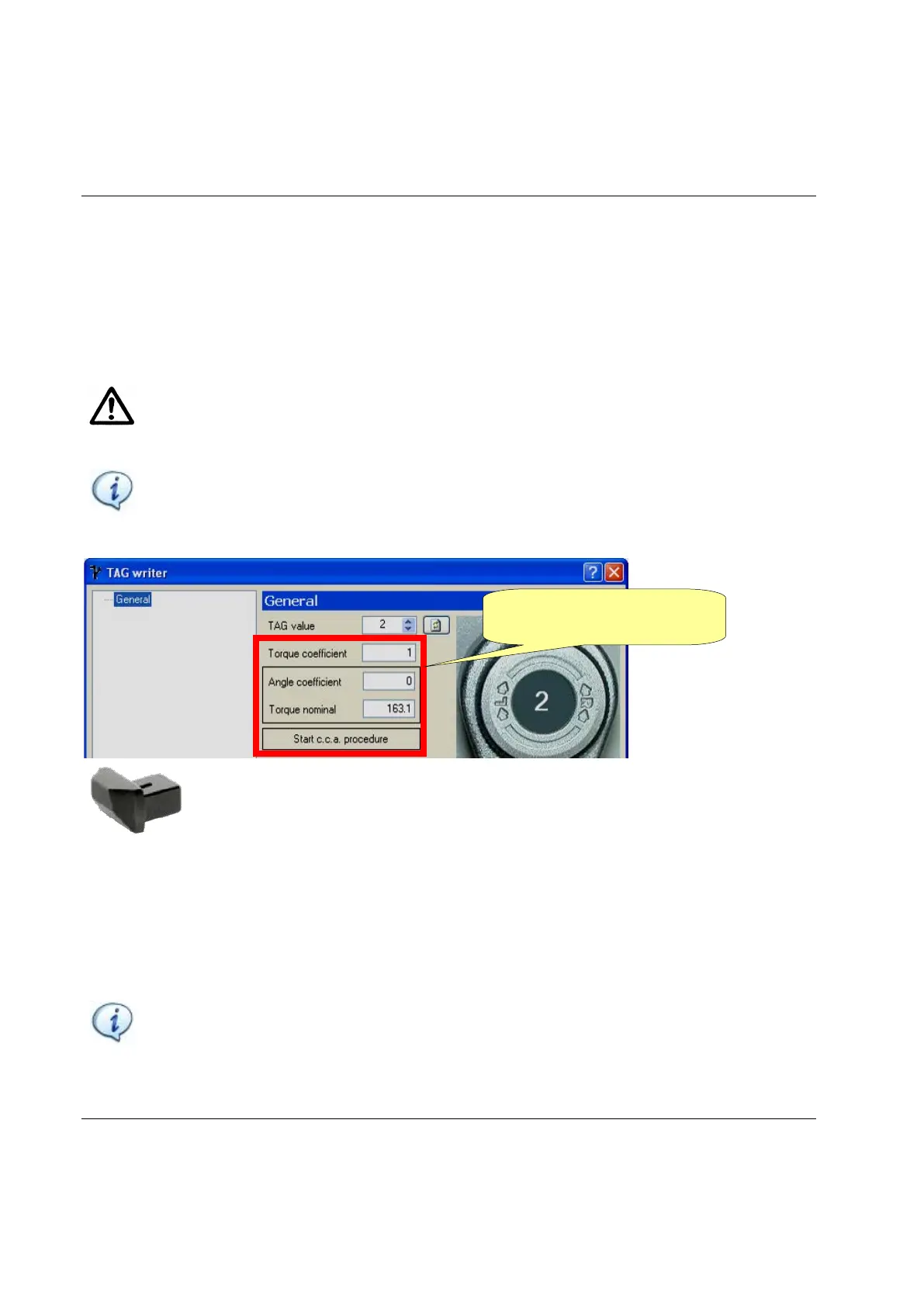

If these two coefficients are already known, simply write them in this window and click on Set to store

them in the RFID TAG of the end-fitting tool plugged into the smartHEAD. The Angle coefficient is

referred to a Torque nominal, which must be specified together with the coefficient. The Torque Nominal

is the torque value at which the bending angle has been measured.

If these two coefficients are not already known, see the chapter Appendix A – Calculating Torque and

Angle Correction Coefficients for a detailed description on how to calculate them.

NOTE: It is also possible to define these coefficients in the Pset parameters (see the Pset

Options) instead of writing them in the end-fitting tool TAG. This can be used when you use an

extension without the black end-fitting tool.

Torque and Angle correction

coefficients

Loading...

Loading...