Pset STwrench User Guide

124 (326) 9836 4134 01 Edition 2.9

6.7.2.1 Yield Point (JOINT ANALYSIS)

This strategy is the same used for the yield point production strategy; in quality control you can use this to

evaluate the stiffness of a joint, extracting information about the yield point.

You need to specify the torque limits within which to look for the yield point (outside the limits the torque

trace in not analyzed).

In joint analysis, the target angle is normally left set to zero; a specific target angle can be used for

tightening to the yield point (see the Yield Point chapter).

In joint analysis, instead of setting the torque limits in a narrow range, define a wider area in which to look

for the yield point. At the end of the tightening operation, you can download the trace to analyze the joint

in details.

Define a wide range for the angle limits (i.e. Min. Angle set to 0 and Max. Angle set to 999 degrees).

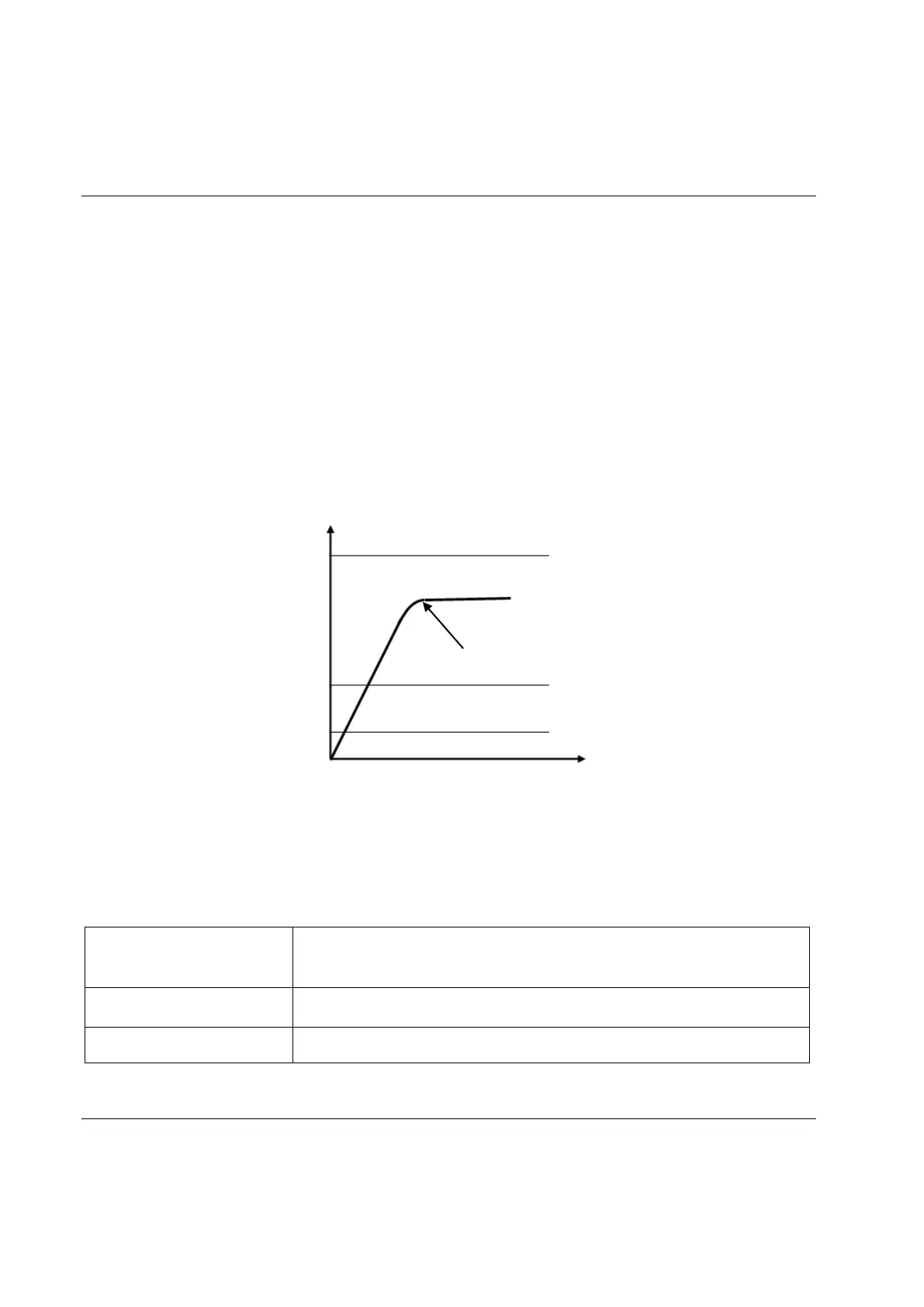

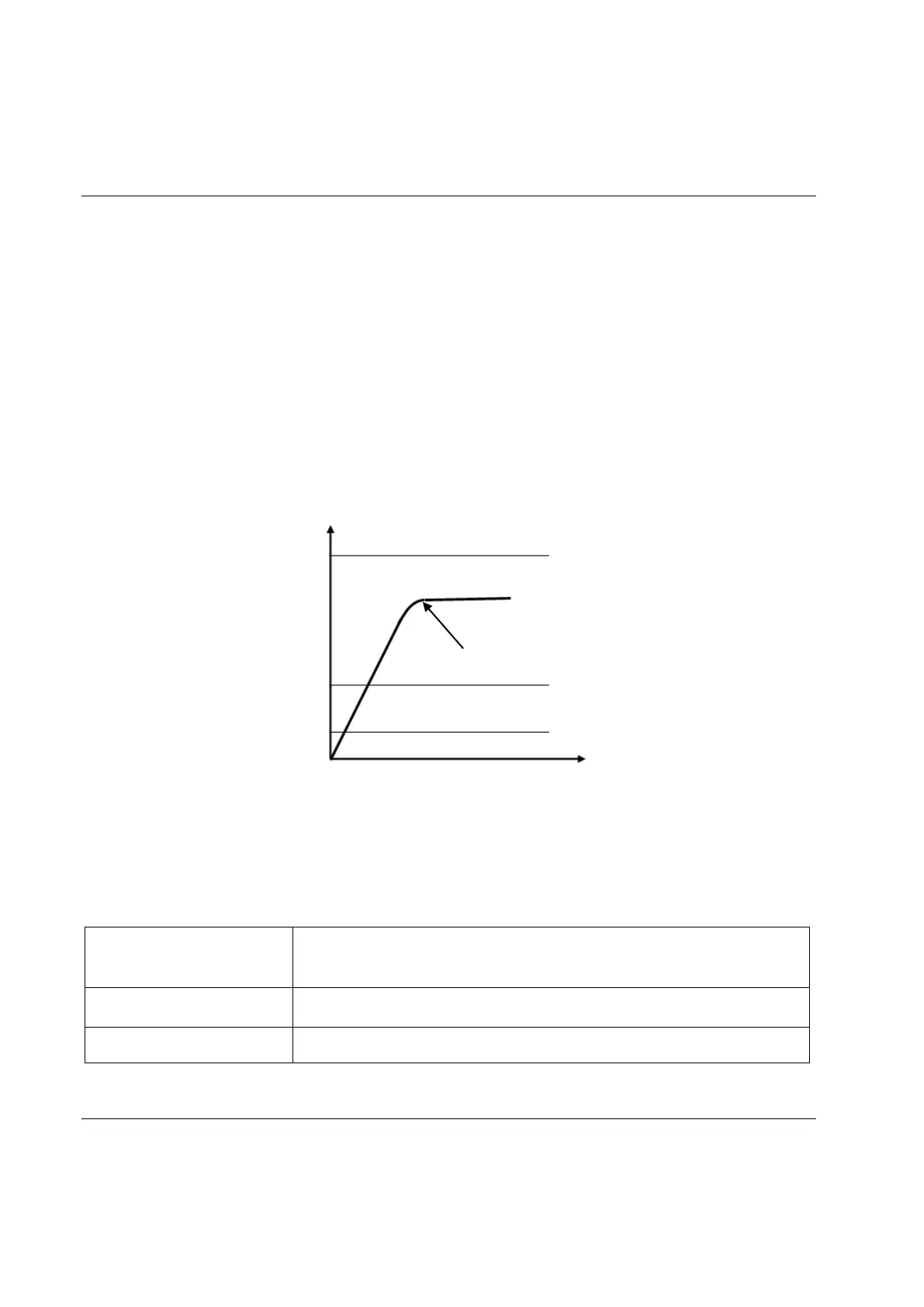

The STwrench LEDs, buzzer and vibration devices are activated as follows:

Torque result between the Cycle Start and the Min. Torque value, or Min.

Torque or Max. Torque but the yield point has not been detected.

Yield point is detected (within torque limits).

Torque result over Max. Torque or angle result over Max. Angle.

Loading...

Loading...