STwrench User Guide Pset

9836 4134 01 Edition 2.9 127 (326)

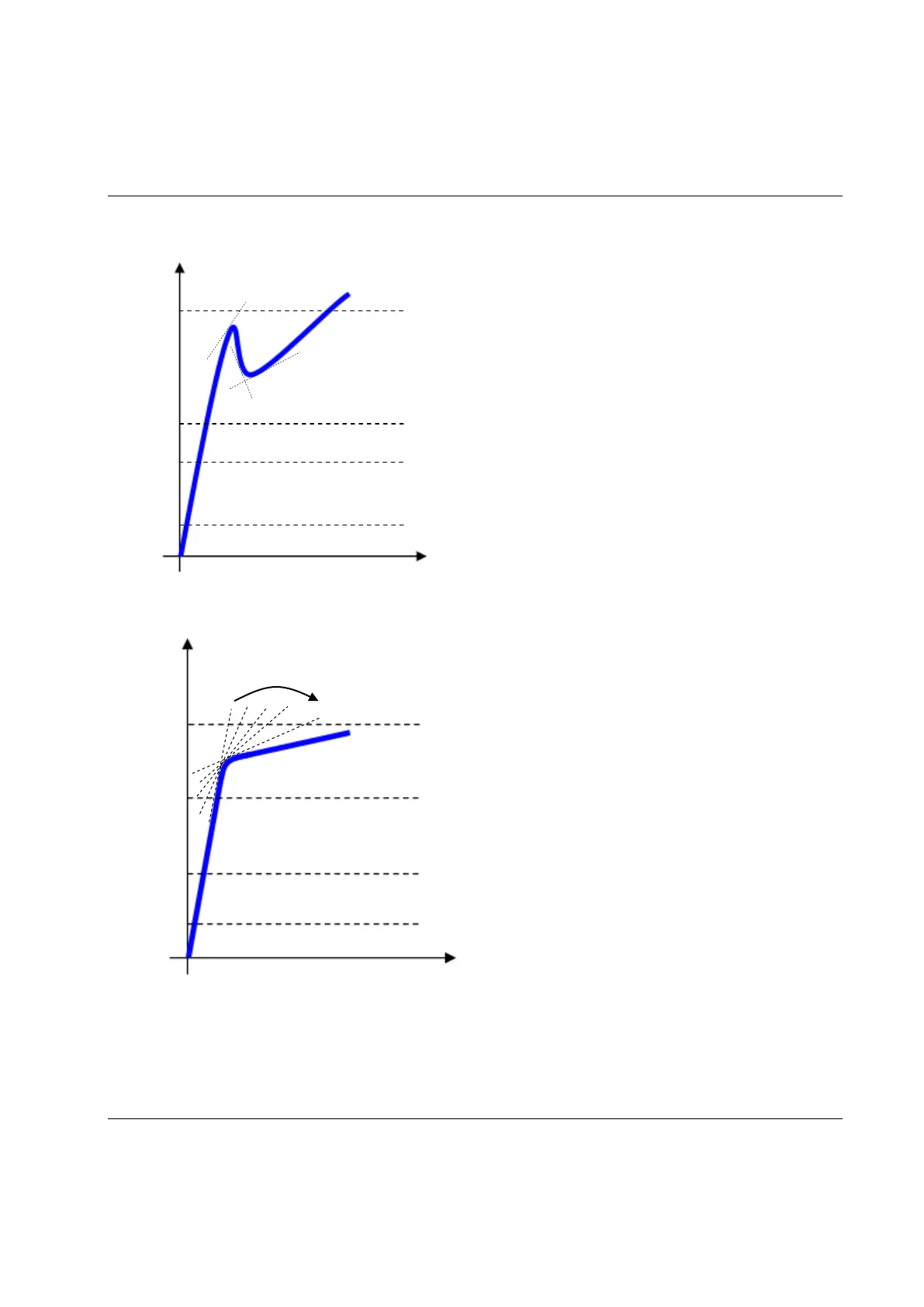

CASE A:

Sometimes very high static friction is built into the joint

(for instance, for no lubrication, conical seat). In that

case, as soon as the bolt moves, the torque decreases and

the real residual torque is lower than the peak torque

necessary to overcome the static friction.

The STwrench algorithm monitors the α

average

; if it goes

to a negative value, it waits until the α

average

goes back to

a positive value.

The point in which the α

average

goes back to a positive

value is considered as the residual torque.

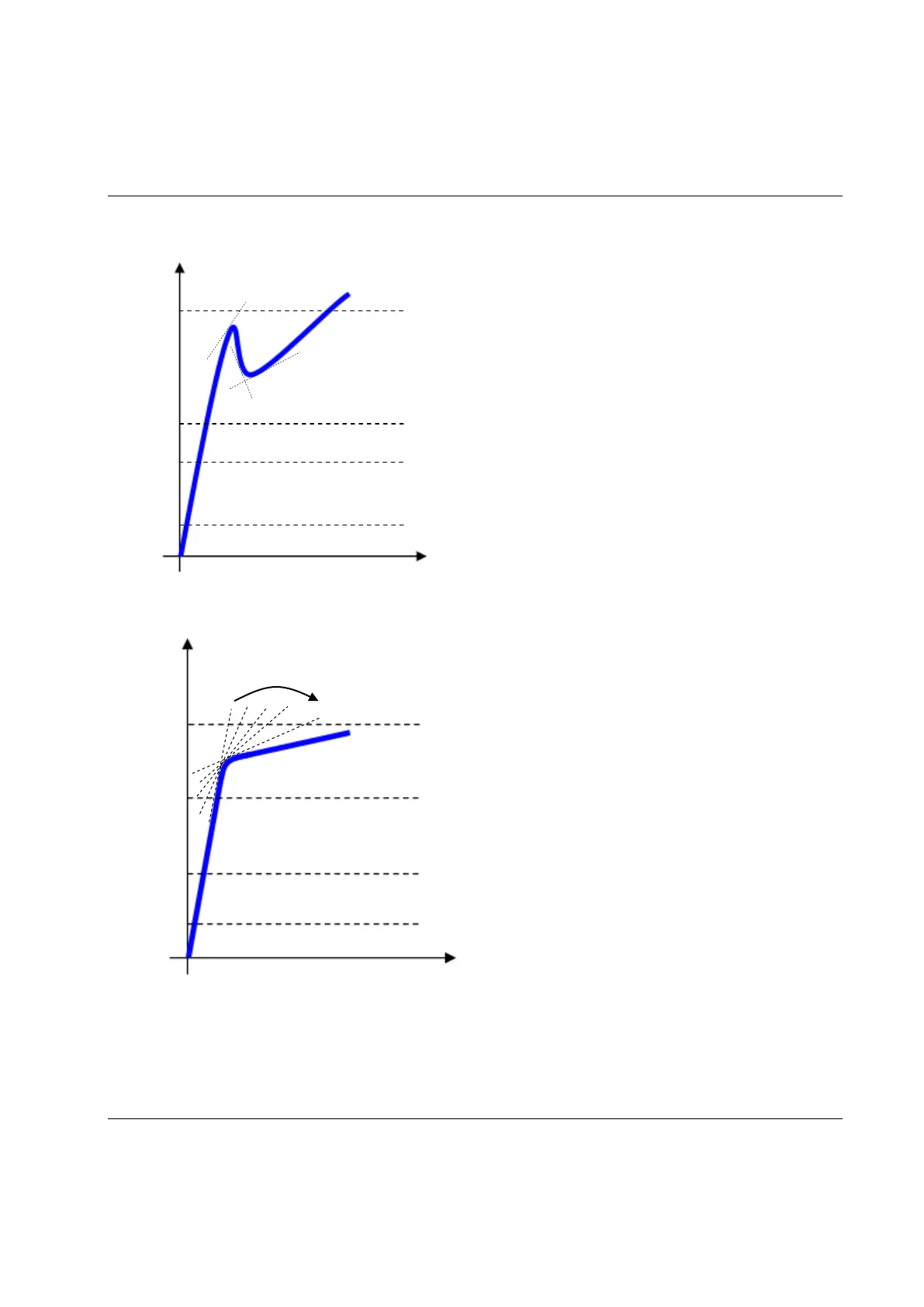

CASE B:

Normally during breakaway, there is a rapid change

of the gradient of the torque/time function when the

bolt starts moving.

The STwrench algorithm monitors the last 14

values α

average

: If all of them are decreasing, and the

last one is less than the 40% of the first one, the

breakaway/residual point is detected.

NOTE: When the algorithm detects the breakaway,

it still waits for 30 milliseconds in order to monitor

if the gradient goes to a negative value; in that case

the algorithm continues analyzing the torque/time

trace as described in CASE A.

How to set parameters:

- Cycle start: This is the point from where the torque is measured. Set to a low value, but

greater than the wrench minimum load.

- Torque min: Minimum residual value for having result OK.

average

> 0

average

> 0

average

< 0

Torque

Torque max

Cycle start

Start final angle

Loading...

Loading...