Chapter 51-00-00 Standard Practices

51-00-10 Safety Wiring

Safety wire is used to secure fasteners to prevent them from coming lose. It's used a lot in aviation

and racing. To safety wire fasteners you will need safety wire, safety wire pliers, wire cutters (dykes),

and needle nose pliers. In a pinch, you can make do with the wire and needle-nose pliers with a

cutting edge. The hardest part of safety wiring is drilling the holes in the hardened fasteners. There

are jigs available to hold nuts and bolts so they can be drilled more easily. You may also be able to

purchase pre-drilled fasteners and save yourself some time. Safety wire comes in many types and

sizes. You must first select the correct type and size of wire for the job. Annealed corrosion-resistant

steel or stainless steel wire is used in race preparation.

51-00-11 The following Alternator rules apply to safety wiring

1. All safety wires must be tight after installation, but not under so much tension that

normal handling or vibration will break the wire.

2. The wire must be applied so that all pull exerted by the wire tends to tighten the nut.

3. Twists should be tight and even, and the wire between nuts as taut as possible

without over-twisting. Safety wire pliers can easily twist the wire too far, breaking or

weakening it.

4. Twist ends should routed so that no injured ours

For this reason, wire between nuts should be twisted with the hands. The use of pliers may damage

the wire. Pliers should be used only for final end twist before cutting excess wire

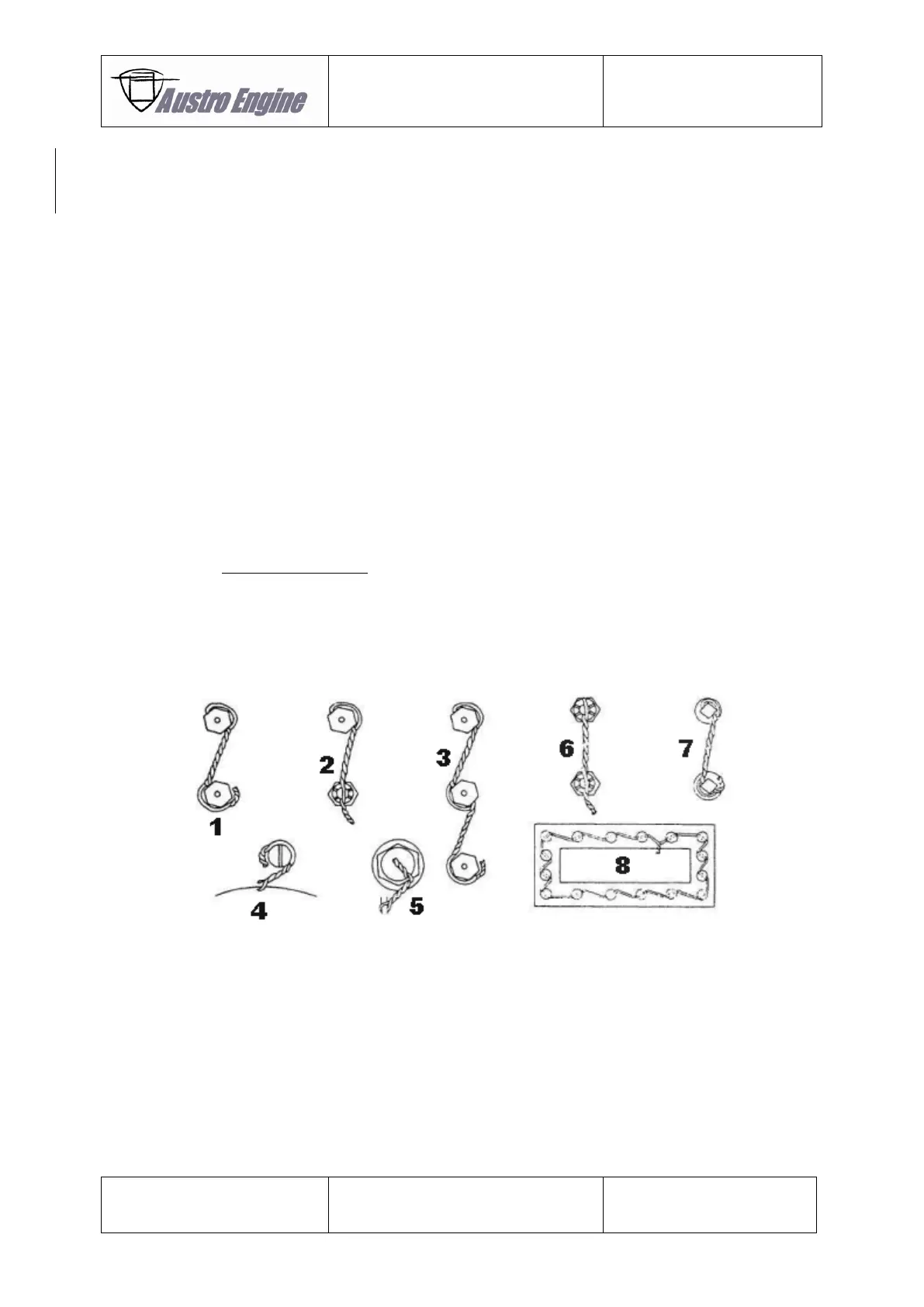

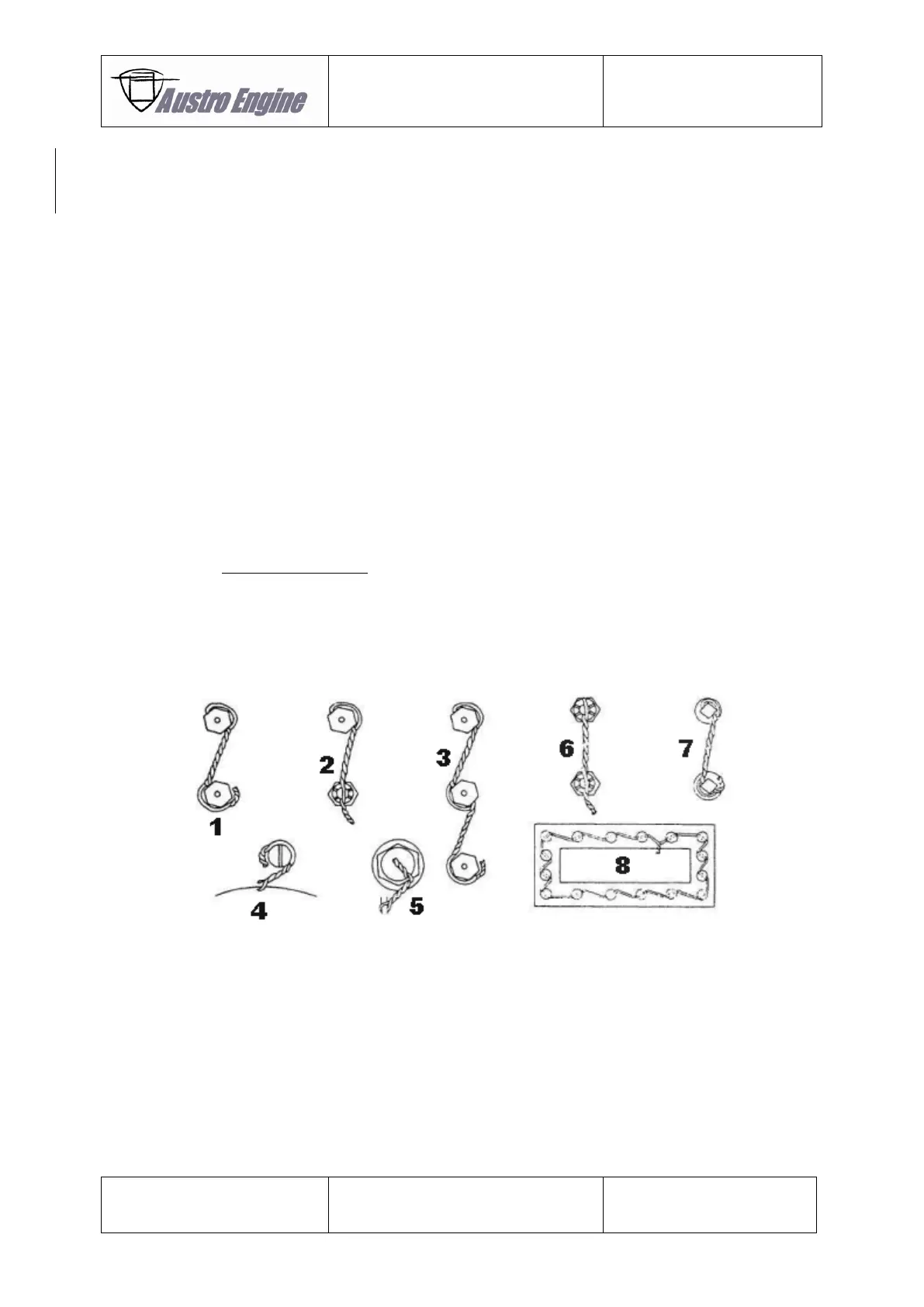

Fig. 51 - 1

Patterns

All critical nuts except the self-locking types must be safe tied; the method used depends upon the

particular installation. The illustration at left shows various methods commonly used in safety wiring

nuts, bolts, and screws. Examples 1, 2, and 7 show the proper method of safety wiring bolts, screws,

square head plugs, and similar parts when wired in pairs. Examples 4 and 5 show a single threaded

component wired to a housing or lug. Example 3 shows several components wired in series. Example

6 shows the proper method of wiring castellated nuts and studs. Note that there is no loop around the

nut. Example 8 shows several components in a closely spaced, closed geometrical pattern, using the

single-wire method.

Loading...

Loading...